At its core, an electric muffle furnace is a high-temperature oven designed for processes that demand exceptional temperature uniformity and a contamination-free environment. It achieves this by using a distinct inner chamber, the "muffle," which isolates the material being heated from the furnace's electric heating elements, ensuring clean and consistent results.

While many ovens can produce high temperatures, a muffle furnace is specifically engineered for applications where the purity of the sample and the precision of the heat treatment are paramount. Its function is not just to heat, but to heat cleanly and uniformly.

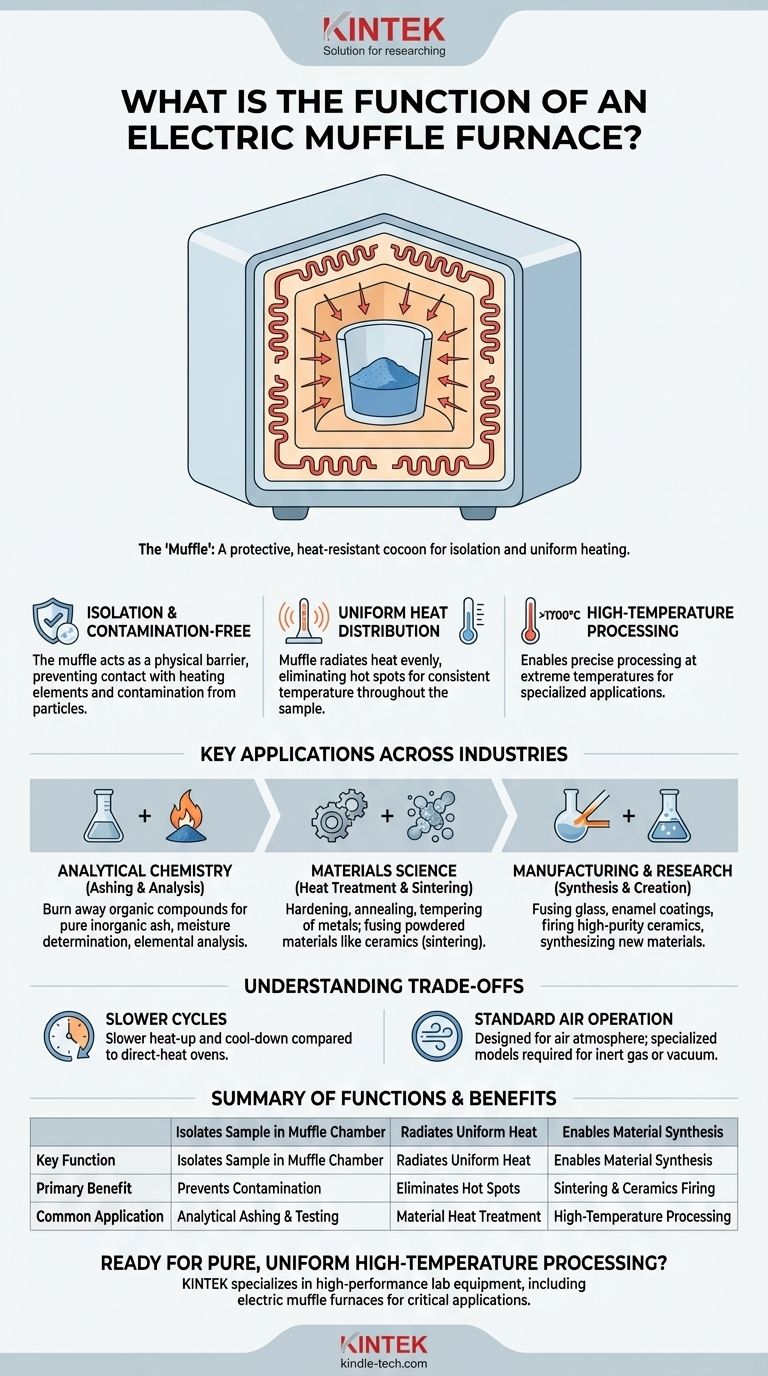

The Defining Principle: What Is the "Muffle"?

The key to understanding the furnace's function lies in the muffle itself. This component is not just a container; it is the central element that defines the furnace's unique capabilities.

The Role of Isolation

Think of the muffle as a protective cocoon for your sample. It's a heat-resistant box, typically made of ceramic, that sits inside the main furnace cavity. The heating elements heat the muffle, and the muffle then radiates that heat evenly onto the sample inside.

This design prevents the sample from being exposed to the harsh, direct radiation of the heating coils.

Ensuring Contamination-Free Processing

Historically, muffles were designed to protect materials from soot and fumes produced by fuel combustion. In a modern electric furnace, the principle remains vital.

The muffle acts as a physical barrier, preventing any microscopic particles from the degrading heating elements or insulation from falling onto and contaminating the sample. This is critical for sensitive analytical work.

Delivering Uniform Heat

By absorbing and then radiating energy, the muffle eliminates hot spots. It ensures the entire sample experiences the same temperature, which is essential for predictable chemical reactions, consistent material transformations, and accurate analysis.

Key Applications Across Industries

The muffle's unique properties make the furnace indispensable for specific high-temperature tasks where precision is non-negotiable.

Analytical Chemistry: Ashing and Analysis

The most common use in a laboratory is ashing. This process involves heating a sample to burn away all organic compounds, leaving only the inorganic ash behind for measurement and analysis.

The muffle's clean environment ensures that the final weight is purely the sample's inorganic content, without added contaminants. It is also used to determine moisture, volatile matter, and perform elemental analysis.

Materials Science: Heat Treatment and Sintering

In metallurgy and materials science, muffle furnaces are used for precise heat treatments like hardening, annealing (softening), and tempering of metals.

They are also used for sintering, a process where powdered materials (like ceramics or metals) are heated below their melting point until their particles fuse into a solid, coherent mass.

Manufacturing and Research: Synthesis and Creation

These furnaces are used to fuse glass, create durable enamel coatings on metal, and fire high-purity ceramics. In research and development, they are essential for synthesizing new materials at high temperatures in a controlled air atmosphere.

Understanding the Trade-offs

While powerful, a muffle furnace is a specialized tool. Understanding its limitations is key to using it effectively.

Slower Heating and Cooling Cycles

Because the heat must first saturate the muffle before reaching the sample, these furnaces generally have slower heat-up and cool-down times compared to direct-heat ovens. This can impact throughput in a busy lab.

Standard Operation in Air

A standard electric muffle furnace is designed to operate in a normal air atmosphere. Processes requiring an inert gas (like argon) or a vacuum to prevent oxidation require significantly more complex and expensive specialized furnace models.

Not a Simple Drying Oven

Using a muffle furnace for simple low-temperature applications, like drying glassware, is inefficient. A standard laboratory or convection oven is faster and more energy-efficient for tasks that do not require high temperatures or a protected atmosphere.

Making the Right Choice for Your Goal

Selecting the correct heating instrument depends entirely on your objective.

- If your primary focus is analytical purity (ashing, elemental analysis): The muffle furnace is the correct tool, as it provides the necessary contamination-free environment for accurate results.

- If your primary focus is materials transformation (heat treating, sintering, ceramics): The uniform and high heat of a muffle furnace ensures predictable and consistent material properties.

- If your primary focus is simple drying or low-temperature heating (below 250°C): A standard convection or gravity oven is a more efficient and cost-effective choice.

Ultimately, understanding the role of the muffle transforms the furnace from a simple heat source into a precision instrument for material analysis and creation.

Summary Table:

| Key Function | Primary Benefit | Common Application |

|---|---|---|

| Isolates Sample in Muffle Chamber | Prevents Contamination | Analytical Ashing & Testing |

| Radiates Uniform Heat | Eliminates Hot Spots | Material Heat Treatment |

| High-Temperature Processing (up to 1700°C+) | Enables Material Synthesis | Sintering & Ceramics Firing |

Ready to achieve pure, uniform high-temperature processing in your lab?

KINTEK specializes in high-performance lab equipment, including electric muffle furnaces designed for critical applications like ashing, heat treatment, and sintering. Our furnaces deliver the contamination-free environment and precise temperature control your work demands.

Contact our experts today to find the perfect muffle furnace for your specific laboratory needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the working principle of a muffle furnace? Achieve Precise, Contamination-Free Heating

- What precautions should be taken while heating and cooling the crucible? Prevent Thermal Shock and Ensure Safety

- What is the melting temperature of ceramics? Understanding High-Temperature Material Performance

- What is the burning temperature of a furnace? From 200°C to 3000°C, It Depends on Your Needs

- What is a muffle furnace used for in microbiology? Essential for Depyrogenation and Ashing