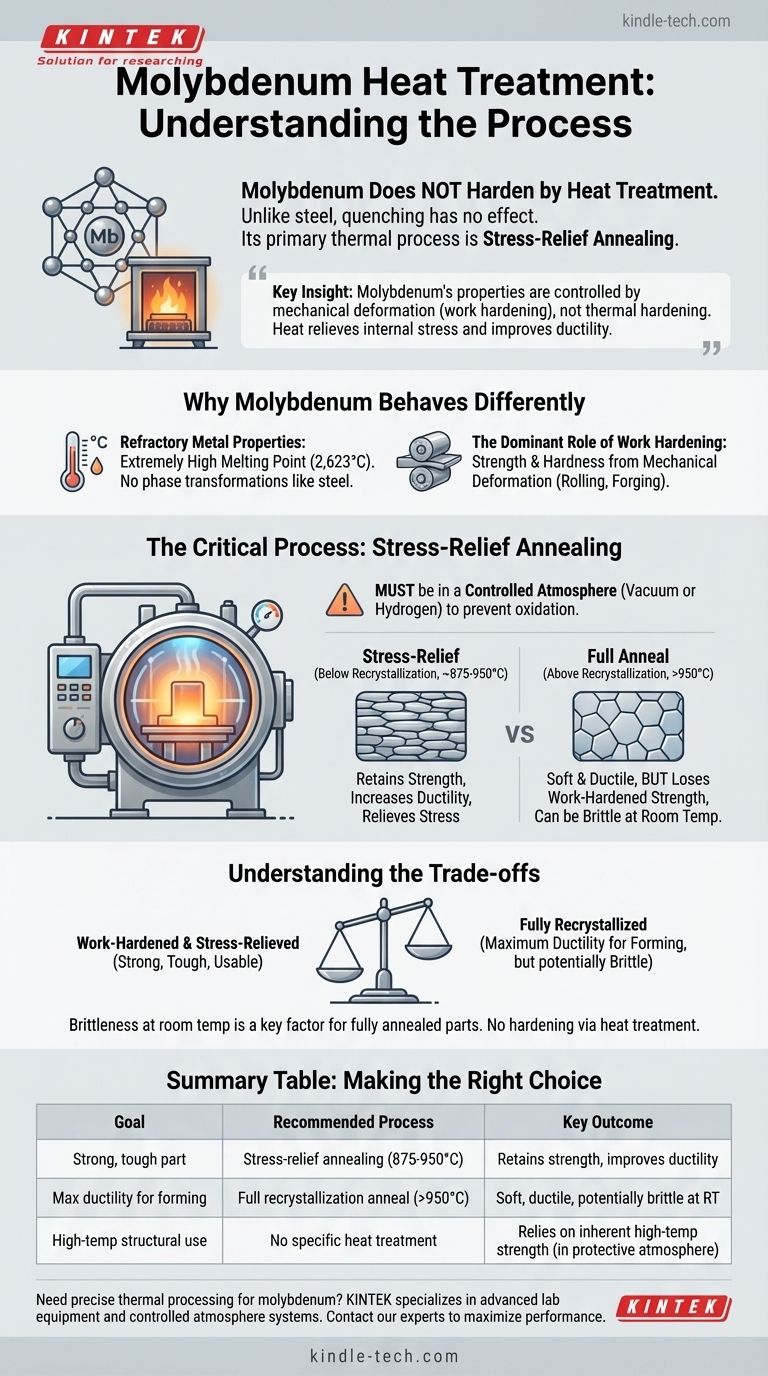

For molybdenum, "heat treatment" is fundamentally different from the hardening processes used for steel. Molybdenum does not respond to quenching and tempering to increase its hardness. Instead, the primary thermal process it undergoes is stress-relief annealing, which is used to increase its ductility and reduce the risk of fracture after it has been strengthened through mechanical work.

The key to understanding molybdenum is realizing its properties are controlled by mechanical deformation (work hardening), not thermal hardening. Heat is applied primarily to relieve internal stress and improve ductility, a process that must be done in a vacuum or hydrogen atmosphere to prevent catastrophic oxidation.

Why Molybdenum Behaves Differently

To effectively work with molybdenum, one must first understand why its metallurgy diverges so significantly from common alloys like steel.

Refractory Metal Properties

Molybdenum is a refractory metal, defined by its extremely high melting point (2,623 °C or 4,753 °F). Unlike steel, it does not undergo the phase transformations at lower temperatures that enable hardening through processes like quenching.

The Dominant Role of Work Hardening

The primary method for increasing the strength and hardness of molybdenum is work hardening (or cold working). This involves mechanically deforming the metal—through rolling, forging, or drawing—at a temperature below its recrystallization point. This process elongates the grain structure and introduces dislocations that make the material stronger but also more brittle.

The Purpose of Thermal Treatment: Relieving Stress

After work hardening, molybdenum is left with significant internal stresses. Applying heat—a process known as stress-relieving or process annealing—allows these internal stresses to relax without fundamentally changing the work-hardened grain structure. This restores some ductility and makes the material far more usable.

The Critical Process: Stress-Relief Annealing

This is the most common and important thermal process for molybdenum. The goal is to make the material tougher and less brittle without sacrificing the strength gained from work hardening.

Temperature and Recrystallization

The outcome of annealing depends entirely on the temperature.

- Stress-Relief (Below Recrystallization): Heating molybdenum to a temperature below its recrystallization point (typically 875-950°C) relieves stress, slightly reduces hardness, and significantly increases its ductility. The work-hardened strength is mostly retained.

- Full Anneal (Above Recrystallization): Heating above the recrystallization temperature causes new, stress-free grains to form. This makes the molybdenum very soft and ductile, ideal for extensive forming operations, but it erases the strength benefits of work hardening.

The Necessity of a Controlled Atmosphere

Molybdenum begins to oxidize rapidly in air at temperatures above 400°C. Therefore, any stress-relieving or annealing process must be performed in a protective atmosphere, such as a high vacuum or dry hydrogen. Heating molybdenum in air will destroy the material.

Understanding the Trade-offs

Working with molybdenum requires acknowledging its unique limitations and metallurgical trade-offs.

The Brittleness of Recrystallized Molybdenum

While a full recrystallization anneal makes molybdenum highly ductile for forming, the large grain structure it creates can make the final part very brittle at room temperature. This phenomenon, known as the ductile-to-brittle transition temperature (DBTT), is a critical design consideration. Stress-relieved molybdenum generally has better room-temperature toughness.

The Oxidation Challenge

The need for a vacuum or hydrogen atmosphere is an absolute, non-negotiable requirement for any high-temperature processing. This adds significant complexity and cost compared to working with metals that are stable in air.

No Hardening via Heat Treatment

It is critical to repeat: you cannot harden molybdenum through heat treatment. Attempting to quench it from a high temperature will not increase its hardness and will likely introduce thermal stress and cracking. Strength is built through mechanical work, not thermal cycles.

Making the Right Choice for Your Goal

The correct thermal process for molybdenum is entirely dependent on your desired outcome.

- If your primary focus is a strong, tough, and usable final part: Use stress-relief annealing on a work-hardened component to retain strength while improving toughness.

- If your primary focus is maximum ductility for severe forming or bending: Use a full recrystallization anneal, but be prepared for the final part to be softer and potentially brittle at room temperature.

- If your primary focus is high-temperature structural use: The material's inherent high-temperature strength is key; the main consideration is ensuring the operating environment is a vacuum or reducing atmosphere to prevent oxidation.

Ultimately, controlling molybdenum's properties is a precise balance between mechanical deformation and subsequent thermal stress relief, not traditional hardening.

Summary Table:

| Goal | Recommended Process | Key Outcome |

|---|---|---|

| Strong, tough final part | Stress-relief annealing (875-950°C) | Retains work-hardened strength, improves ductility |

| Maximum ductility for forming | Full recrystallization anneal (>950°C) | Soft, ductile material (may be brittle at room temp) |

| High-temperature structural use | No specific heat treatment required | Relies on inherent high-temp strength in protective atmosphere |

Need precise thermal processing for your molybdenum components? KINTEK specializes in advanced lab equipment and consumables for high-temperature applications. Our expertise in controlled atmosphere systems ensures your molybdenum parts are processed correctly, maximizing their performance and durability. Contact our experts today to discuss your specific laboratory needs and discover the right solution for your project.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How can the temperature rise of a furnace be reduced if it is too high? Fix Airflow Issues for Safe & Efficient Heating

- What is the critical temperature of heat treatment? Unlock the Key to Steel's Hardness and Performance

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- How hot does a furnace heat exchanger get? Understand Safe Operating Temperatures to Prevent Hazards

- Can an arc happen in a vacuum? Yes, and here's how to prevent it in your high-voltage design.