The heating rate of induction is not a single value; it is a highly controllable variable and one of the technology's primary advantages. The rate is determined by the power density applied to the workpiece, the operating frequency of the system, and the physical properties of the material being heated. Induction heating is capable of raising the temperature of steel above its Curie point in a matter of seconds.

The speed of induction heating is its defining feature. It is not an inherent constant but a direct result of how much power you can precisely deliver to a specific area of a part, making it one of the fastest heating methods available for industrial processes.

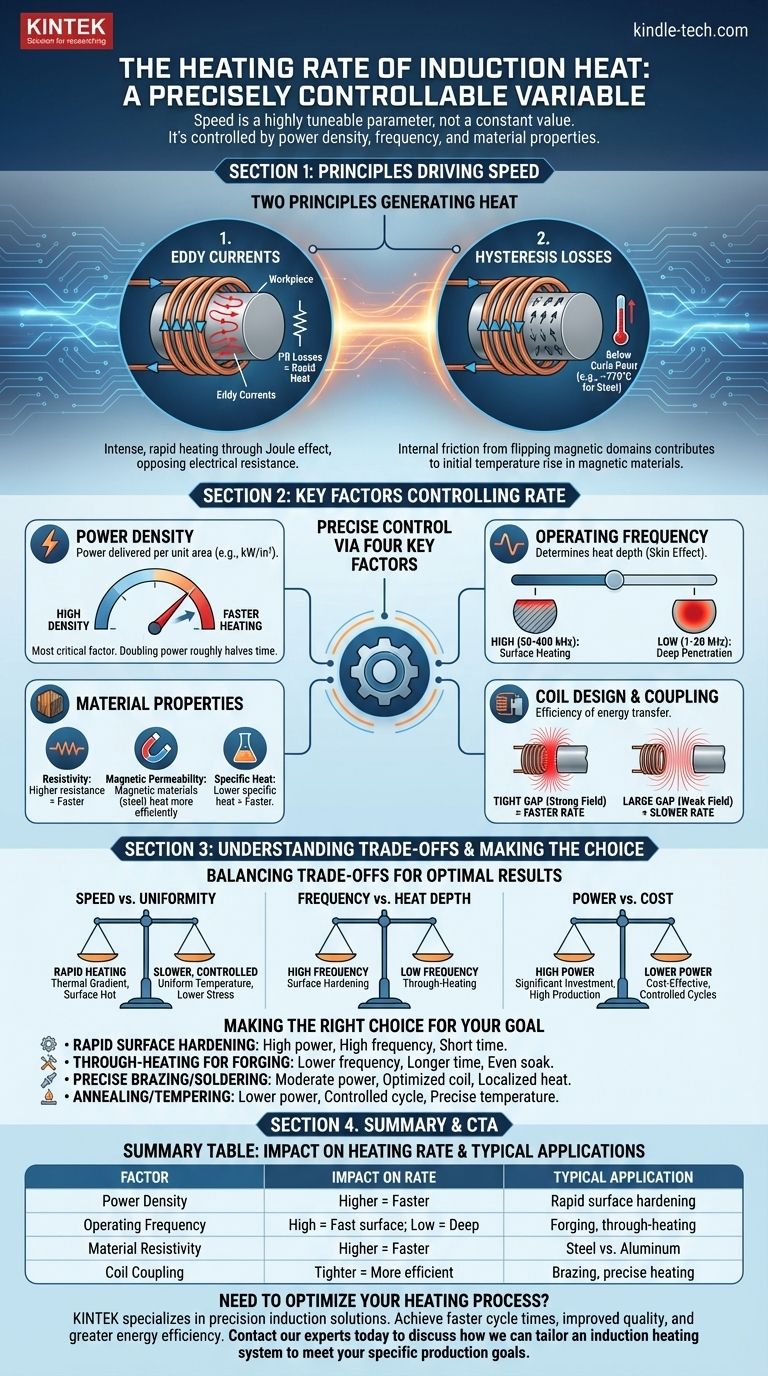

The Principles Driving Induction's Speed

To understand what controls the heating rate, we must first understand how induction generates heat. It relies on two fundamental physical principles that occur when an electrically conductive material is placed within a strong, alternating magnetic field.

Eddy Currents

The primary source of heat is from eddy currents. The alternating magnetic field generated by the induction coil induces these strong, localized electrical currents within the workpiece. The material's natural electrical resistance opposes the flow of these currents, resulting in intense, rapid heating through the Joule effect (I²R losses).

Hysteresis Losses

For magnetic materials like iron and steel, a secondary heating effect occurs. The alternating magnetic field rapidly flips the magnetic domains within the material. This internal friction, called hysteresis loss, generates additional heat below the material's Curie temperature (around 770°C for steel), contributing to the initial rapid temperature rise.

Key Factors Controlling the Heating Rate

You can precisely control the heating rate by manipulating several key system parameters. The "recipe" for your process depends on balancing the following factors.

Power Density

This is the most critical factor. Power density refers to the amount of power from the induction power supply delivered per unit of surface area (e.g., kilowatts per square inch). A higher power density results in a faster heating rate. Doubling the power delivered to the same area will roughly halve the time it takes to reach a target temperature.

Operating Frequency

The frequency of the alternating current determines the depth to which the eddy currents penetrate the material, a phenomenon known as the skin effect.

- High Frequencies (50 kHz - 400 kHz): Current flows in a thin layer at the surface, leading to extremely fast surface heating. This is ideal for surface hardening.

- Low Frequencies (1 kHz - 20 kHz): Current penetrates deeper into the part, which is necessary for through-heating large billets for forging or forming.

Material Properties

The material of the workpiece itself plays a crucial role.

- Resistivity: Materials with higher electrical resistance heat more quickly because they generate more heat from the same amount of induced current.

- Magnetic Permeability: Magnetic materials like steel heat far more efficiently than non-magnetic materials like copper or aluminum due to the added effect of hysteresis.

- Specific Heat: This is the amount of energy required to raise the material's temperature. Materials with lower specific heat will heat up faster with the same power input.

Coil Design and Coupling

The induction coil acts as the "applicator" that transfers energy to the part. Coupling efficiency—the proximity of the coil to the workpiece—is vital. A small gap between the coil and the part ensures a strong magnetic field and efficient energy transfer, resulting in a faster heating rate.

Understanding the Trade-offs

While speed is a major benefit, achieving the optimal heating rate requires balancing competing factors. Pushing for the maximum possible speed is not always the best solution.

Speed vs. Temperature Uniformity

Heating a part extremely quickly can create a significant thermal gradient, where the surface is much hotter than the core. For processes like through-hardening or tempering, a slower, more controlled heating rate using a lower frequency is required to ensure a uniform temperature distribution and prevent internal stresses or cracking.

Frequency vs. Heat Depth

The choice of frequency is a direct trade-off. If you need to heat the entire cross-section of a thick bar, a high frequency that only heats the surface will be ineffective. You must select a frequency that allows the heat to penetrate to the desired depth for your specific application.

Power vs. Cost

A power supply capable of delivering very high power for rapid heating represents a significant capital investment. The required heating rate must be justified by the production demands of the process to ensure a positive return on investment.

Making the Right Choice for Your Goal

The "correct" heating rate is entirely dependent on your application's objective. To determine your needs, consider the desired outcome.

- If your primary focus is rapid surface hardening: Use high power density and a high operating frequency to heat only the surface layer in a few seconds.

- If your primary focus is through-heating a large part for forging: Use a lower frequency and a longer heating time to allow the thermal energy to soak evenly through the entire workpiece.

- If your primary focus is precise brazing or soldering: Use a moderate power level with a carefully designed coil to heat a very specific joint area without affecting surrounding components.

- If your primary focus is annealing or tempering: Use lower power and a controlled cycle time to achieve and hold a precise temperature for metallurgical purposes.

Ultimately, the heating rate in an induction system is a precisely engineered parameter, not an accidental outcome.

Summary Table:

| Factor | Impact on Heating Rate | Typical Application |

|---|---|---|

| Power Density | Higher power = Faster rate | Rapid surface hardening |

| Operating Frequency | High frequency = Fast surface heating; Low frequency = Deep heating | Forging, through-heating |

| Material Resistivity | Higher resistance = Faster heating | Steel vs. Aluminum |

| Coil Coupling | Tighter gap = More efficient transfer | Brazing, precise heating |

Need to optimize your heating process?

KINTEK specializes in precision lab equipment and industrial heating solutions. Whether you require rapid surface hardening, uniform through-heating for forging, or precise temperature control for brazing, our expertise in induction technology can help you achieve faster cycle times, improved product quality, and greater energy efficiency.

Contact our experts today to discuss how we can tailor an induction heating system to meet your specific production goals.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

People Also Ask

- Which furnace is for melting most non ferrous metals? Induction Furnaces for Superior Purity & Efficiency

- Is an induction furnace AC or DC? Discover the Core Principle of Induction Heating

- What is the difference between arc melting and induction melting? Power vs. Precision for Your Metal Melting Needs

- What are the factors affecting choice of frequency in induction heating? Optimize Your Heat Treatment Process

- How does providing a high-purity argon gas environment within an induction melting furnace affect Cantor alloys?

- What is the temperature range of an induction furnace? From 1250°C to Over 2000°C for Your Specific Application

- What is the temperature of the glass-melting furnace? Achieve Perfect Melting from 1600°C to 2000°C

- What is the basic lining material for induction furnace? The Critical Choice for Safe & Efficient Melting