Hot Isostatic Pressing (HIP) is a materials processing method that uses high temperature and uniform, high-pressure gas to improve the properties of materials. For ceramics, its primary function is to consolidate powders or eliminate residual internal porosity from a pre-formed part, resulting in a fully dense component with significantly enhanced mechanical strength and reliability.

The core purpose of HIP for ceramics is not simply to form a shape, but to transform a component into its highest-performing state. It closes the microscopic voids left by other processes, unlocking the material's full theoretical strength and consistency.

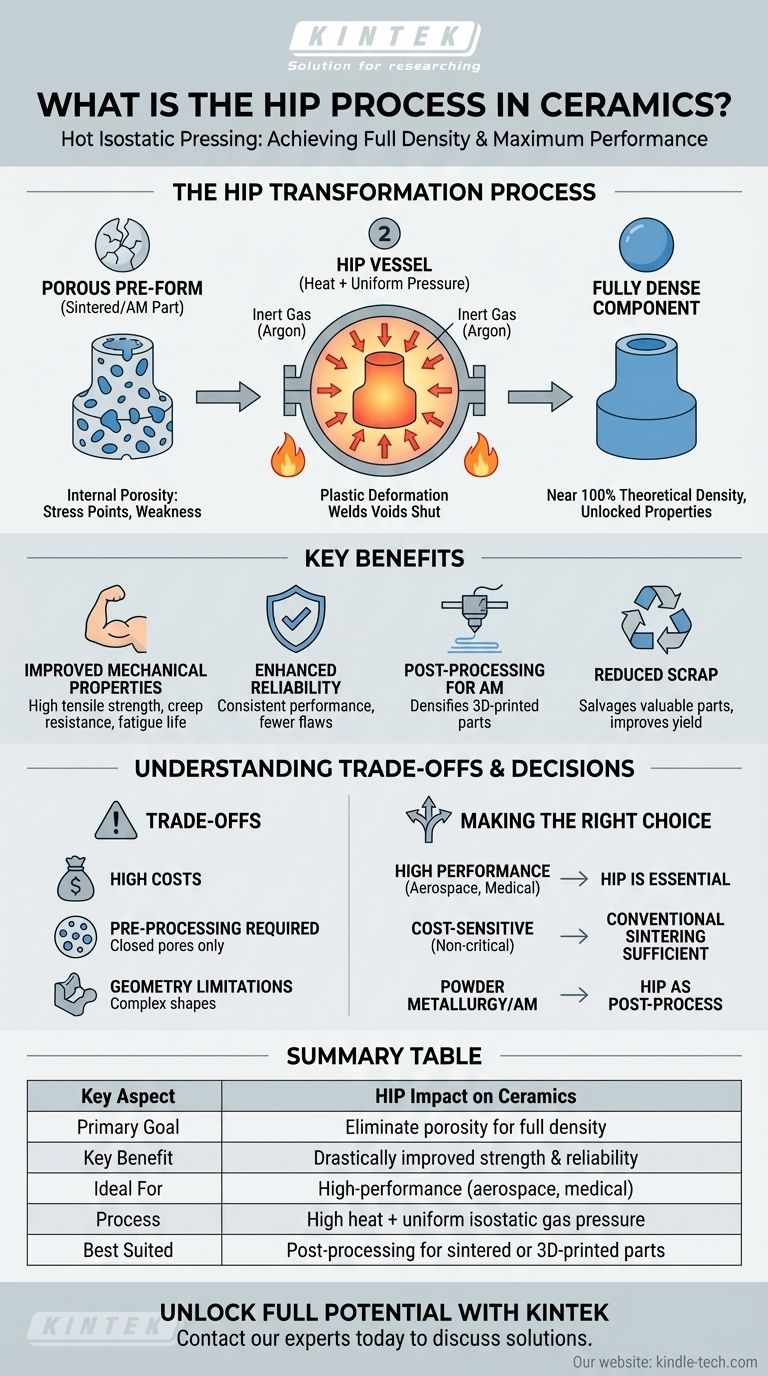

How HIP Transforms Ceramic Materials

To understand the value of HIP, you must first understand the fundamental weakness it solves in ceramics: porosity.

The Problem: Internal Porosity

Most advanced ceramic components begin as a powder. Processes like sintering heat this powder so the particles fuse together, but this often leaves behind tiny, microscopic voids or pores.

This internal porosity acts as a collection of microscopic stress concentration points. When the part is put under load, these voids are the initiation sites for cracks, severely limiting the material's strength, fatigue life, and overall reliability.

The HIP Solution: Heat and Isostatic Pressure

The HIP process places a pre-sintered ceramic part inside a high-pressure vessel. The vessel is heated and filled with a chemically inert gas, typically Argon, creating immense isostatic pressure—pressure that is applied uniformly from all directions.

This combination of high heat and uniform pressure causes the ceramic to plastically deform on a microscopic level. The material "creeps" and collapses into the internal voids, effectively welding them shut and eliminating the porosity.

The Result: Achieving Full Density

The end product is a ceramic component that has reached near 100% of its theoretical maximum density. By eliminating the internal voids that act as failure points, the material's intrinsic properties are unlocked.

Key Benefits of Applying HIP to Ceramics

Applying HIP is an investment that yields significant returns in material performance and manufacturing efficiency.

Drastically Improved Mechanical Properties

By eliminating porosity, HIP significantly improves critical properties like tensile strength, creep resistance, and fatigue life. The material becomes far more durable and resistant to fracture.

Enhanced Reliability and Consistency

HIP reduces the random nature of failures caused by microscopic flaws. This leads to a much smaller variation in material properties from one part to the next, which simplifies design and reduces the need for extensive quality assurance inspections.

Post-Processing for Advanced Manufacturing

HIP is a critical post-processing step for ceramics made via powder metallurgy or additive manufacturing (3D printing). It densifies the "as-printed" or sintered part, transforming it from a porous preform into a high-performance structural component.

Reducing Scrap and Improving Yield

The process can be used to salvage valuable castings or components that would otherwise be rejected due to unacceptable levels of internal porosity found during inspection. This directly improves manufacturing yield and reduces material waste.

Understanding the Trade-offs

While powerful, HIP is not a universal solution. Its application must be weighed against its specific demands and costs.

High Capital and Operational Costs

HIP equipment is expensive to purchase and operate. The high pressures and temperatures require robust, specialized furnaces, making the process cost-prohibitive for non-critical or low-value components. This is why its use is most common in high-stakes industries like aerospace.

Requirement for Pre-Processing

HIP is a densification process, not a shaping one. It requires a part that has already been formed and sintered to a state of "closed porosity," where the internal voids are not connected to the surface. If pores are open to the surface, the pressure gas will simply fill them without closing them.

Limitations on Geometry

While HIP itself applies uniform pressure, the component must be able to withstand the process without distortion. Complex or very thin-walled structures may require careful planning or specialized tooling to maintain their shape during the HIP cycle.

Making the Right Choice for Your Goal

Deciding whether to incorporate HIP depends entirely on the performance requirements of your final component.

- If your primary focus is maximum performance and reliability (e.g., aerospace, medical implants, turbine blades): HIP is often a non-negotiable step to eliminate potential failure points and ensure component safety and longevity.

- If your primary focus is cost-sensitive, non-critical applications: The significant expense of HIP is likely not justified, and conventional sintering will provide sufficient performance for the cost.

- If you are using powder metallurgy or additive manufacturing: View HIP as an essential post-processing step to elevate your component from a porous preform to a fully dense, high-strength part.

Ultimately, HIP is the definitive tool for achieving the absolute peak of a ceramic's potential performance.

Summary Table:

| Key Aspect | HIP Impact on Ceramics |

|---|---|

| Primary Goal | Eliminate internal porosity to achieve full density |

| Key Benefit | Drastically improved mechanical strength & reliability |

| Ideal For | High-performance applications (aerospace, medical) |

| Process | High heat + uniform isostatic gas pressure |

| Best Suited | Post-processing for sintered or 3D-printed parts |

Unlock the Full Potential of Your Ceramic Components with KINTEK

Are you developing high-performance ceramic parts for aerospace, medical, or industrial applications? The HIP process is essential for achieving maximum strength, reliability, and 100% density by eliminating internal porosity.

KINTEK specializes in advanced lab equipment and consumables, including solutions for materials processing like HIP. Our expertise can help you transform your sintered or 3D-printed ceramic preforms into fully dense, high-strength components ready for critical applications.

Contact our experts today to discuss how our solutions can enhance your ceramic manufacturing process and deliver superior material performance.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- How does the high-temperature and high-pressure environment provided by vacuum hot press equipment improve the interfacial bonding between Mo fibers and the TiAl matrix?

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?

- How does a vacuum hot pressing furnace facilitate the preparation of high-density Nb-22.5Cr-5Si alloy bulks? Achieve 99% Density

- What are the advantages of using a vacuum hot pressing furnace over HIP? Optimize Fiber-Foil Composite Production

- Why is it essential to maintain a high vacuum state during hot press sintering? Optimize SiCp/2024Al Quality