The hottest furnaces can reach temperatures over 3,000°C (5,400°F), but this is only achievable in highly specialized laboratory units. For industrial applications like steelmaking, electric arc furnaces operate around 1,800°C (3,300°F). The term "furnace" covers a vast range of technologies, so the maximum temperature depends entirely on its design and purpose.

The maximum temperature of a furnace is not a single number but is instead dictated by its underlying heating technology—such as electric arc, induction, or combustion—and its specific application, from industrial metal melting to precise laboratory experiments.

Why Furnace Type Dictates Temperature Limits

A furnace is fundamentally a tool designed to apply a specific amount of heat for a particular task. A home heating furnace and one used to melt steel solve vastly different problems and are built on different principles.

The core factors determining a furnace's maximum temperature are its heating method, the durability of its construction materials (like refractory linings), and its intended use.

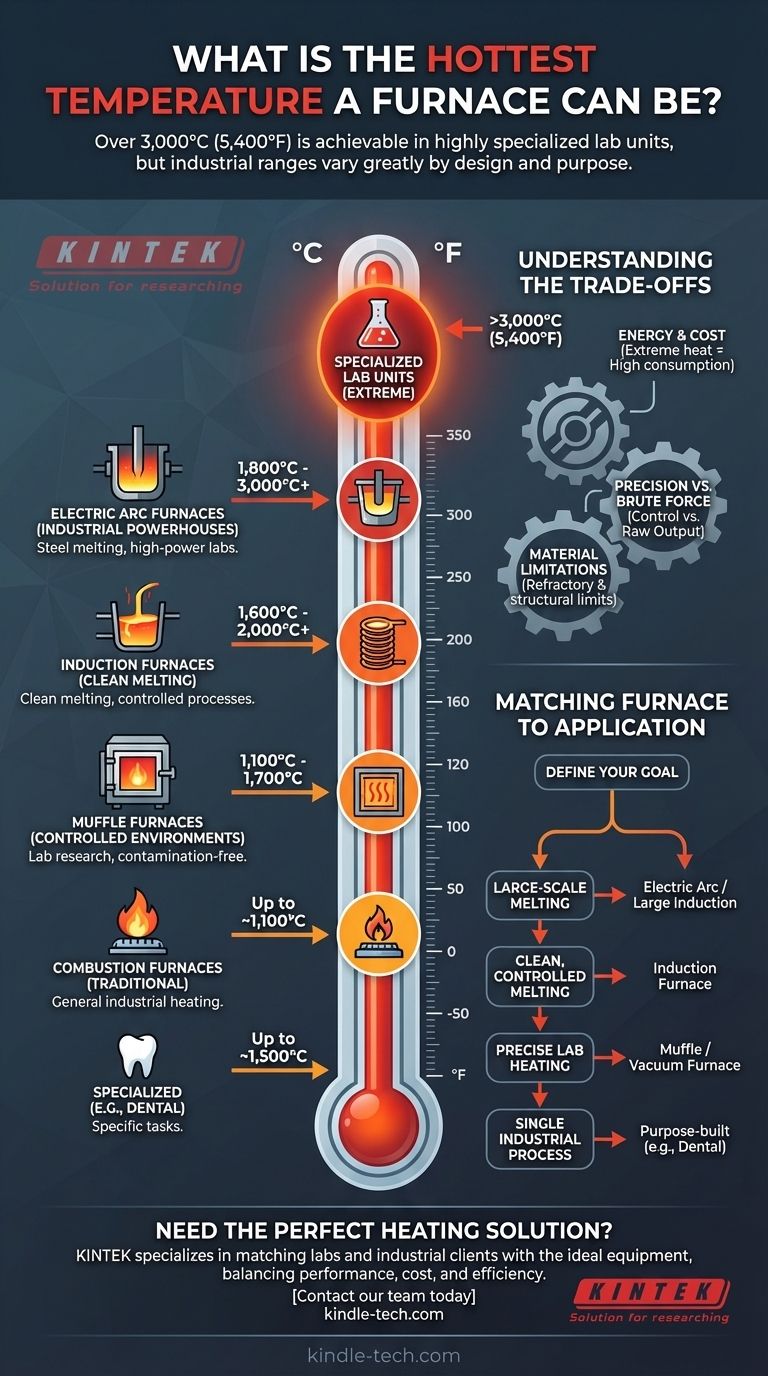

A Breakdown of Furnace Types and Their Temperatures

Different heating technologies have fundamentally different thermal ceilings. Understanding these categories is key to understanding temperature capabilities.

Electric Arc Furnaces: The Industrial Powerhouses

Electric arc furnaces are the workhorses of heavy industry, particularly for melting steel. They use a high-power electric arc between electrodes to generate immense heat.

Industrial models regularly reach 1,800°C (3,300°F), while smaller, highly specialized laboratory versions can exceed 3,000°C (5,400°F).

Induction Furnaces: Heating with Electromagnetism

Induction furnaces use electromagnetic fields to heat conductive materials without direct contact. This allows for clean and controlled melting.

Their maximum temperatures vary by design, with small melting units reaching 1600°C (2900°F) and more powerful industrial models reaching 1800°C or higher. A vacuum induction furnace, which operates in a controlled atmosphere, can achieve temperatures up to 2000°C.

Combustion Furnaces: The Traditional Approach

These furnaces burn fuel, such as natural gas, to create heat. This technology is common but generally has lower temperature limits than its electric counterparts.

A typical natural gas furnace can reach temperatures of up to 1,093°C (2,000°F).

Muffle Furnaces: For Controlled Environments

A muffle furnace isolates the material being heated from the direct heat source, providing a controlled atmosphere and preventing contamination.

These are common in laboratories and for specialized applications. Their temperature ranges vary significantly by design, typically falling between 1,100°C and 1,700°C.

Specialized Furnaces: Designed for a Single Task

Many furnaces are built for one specific purpose, with a temperature range optimized for that task.

A dental furnace, used for processing zirconium oxides in dental crowns, operates up to 1,530°C. This is more than enough for its specific material needs but far below the limits of an arc furnace.

Understanding the Trade-offs

Reaching the absolute highest temperature is rarely the primary goal. Every furnace design involves a series of trade-offs between temperature, cost, efficiency, and control.

Energy Consumption and Cost

Achieving extreme temperatures requires an immense amount of energy. An industrial arc furnace consumes electricity at a massive scale, making its operating cost far too high for applications that don't require its full power.

Precision vs. Brute Force

An electric arc furnace provides immense, raw heat but offers less precise temperature control compared to a laboratory muffle furnace. For scientific research or delicate material processing, control and stability are often more critical than raw thermal output.

Material Limitations

The furnace itself must be able to withstand the temperatures it generates. The refractory materials lining the chamber, the heating elements, and the structural components all have thermal limits that define the furnace's operational ceiling.

Matching the Furnace to the Application

To select the right approach, you must first define your goal. Different objectives demand entirely different tools.

- If your primary focus is large-scale industrial metal melting: An electric arc furnace or a large induction furnace is the industry standard for raw heating power.

- If your primary focus is clean, controlled melting of metals: An induction furnace provides excellent control without contaminating the material with combustion byproducts.

- If your primary focus is precise laboratory heating in a controlled atmosphere: A muffle furnace or a specialized vacuum furnace is the necessary tool.

- If your primary focus is a single, repeatable industrial process: A purpose-built furnace, like a dental furnace, will be the most efficient and cost-effective solution.

Ultimately, understanding a furnace's capabilities begins with defining the specific problem you need to solve with heat.

Summary Table:

| Furnace Type | Typical Maximum Temperature | Primary Application |

|---|---|---|

| Electric Arc Furnace | 1,800°C - 3,000°C+ | Industrial steel melting, high-power labs |

| Induction Furnace | 1,600°C - 2,000°C+ | Clean metal melting, controlled processes |

| Combustion Furnace | Up to ~1,100°C | General industrial heating |

| Muffle Furnace | 1,100°C - 1,700°C | Laboratory research, contamination-free heating |

| Specialized (e.g., Dental) | Up to ~1,500°C | Specific tasks like dental ceramics |

Struggling to find the right furnace for your specific temperature and application needs? At KINTEK, we specialize in matching laboratories and industrial clients with the perfect heating solutions. Whether you require the extreme heat of a lab furnace or the precise control of a muffle furnace for sensitive materials, our experts will help you select equipment that balances performance, cost, and efficiency.

Contact our team today via our form to discuss your project and discover how KINTEK's lab equipment and consumables can optimize your processes and outcomes.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Are biomass and biodiesel truly sustainable? The Surprising Truth Behind Their 'Green' Label

- What are the two main configurations of ULT freezers? Upright vs. Chest for Your Lab's Needs

- What is the necessity of using a laboratory drying oven when processing MoO3/GO composite nanopowders? Find out here.

- What is the process of thin film formation? A Guide to Atomic-Level Surface Engineering

- Can incubator be used for drying? Avoid damaging your samples and equipment

- What is sputter coating? A High-Performance Thin Film Deposition Process

- Why is it necessary to use a high-precision mass flow controller (MFC) in CO2 reduction? Ensure Accurate SPCE Data

- What is the temperature involved in the brazing process? Master the 4 Critical Phases for Perfect Joints