In freeze drying, ultimate vacuum serves as a critical diagnostic metric, not a processing target. It primarily indicates the health of your system—specifically, the efficiency of your vacuum pump and the absence of leaks—rather than the ideal condition for the drying process itself.

The core principle to understand is that while a machine's ability to achieve a very high ultimate vacuum is a sign of good health, running the actual drying process at that maximum vacuum level is counterproductive and will significantly slow it down.

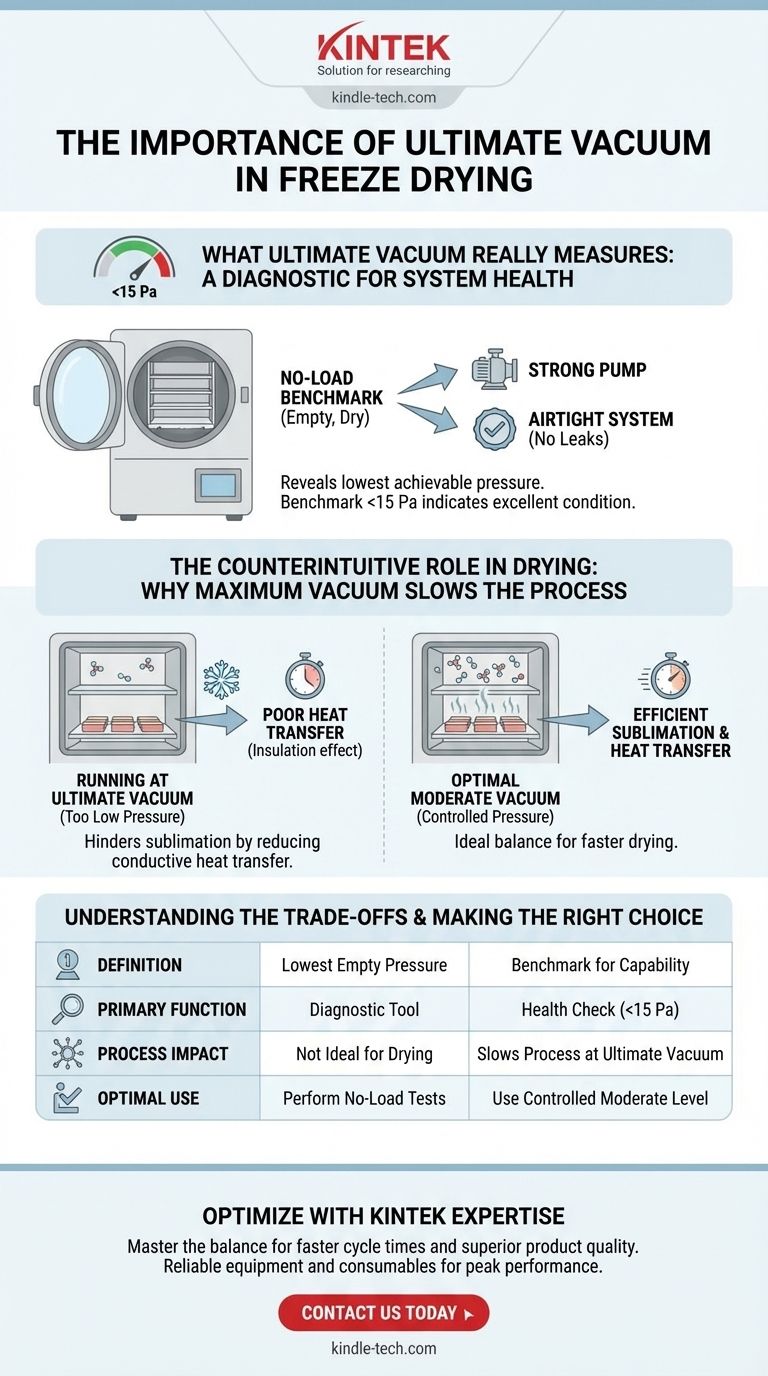

What Ultimate Vacuum Really Measures

Ultimate vacuum is a performance benchmark for the equipment, typically measured when the freeze dryer is clean, dry, and empty (a "no-load" condition). It reveals the lowest pressure your system can possibly achieve.

A Diagnostic for System Health

Think of the ultimate vacuum test as a pressure test for your entire system. A low pressure reading (e.g., below 15 Pascals) signals two positive things: your vacuum pump is strong, and your chamber, seals, and connections are airtight.

If the system cannot reach its specified ultimate vacuum, it almost always points to an air leak or a failing pump.

The No-Load Benchmark

This test is performed without any product in the chamber. The goal is to see what the machine is capable of on its own. A common industry benchmark is for a system to be able to pull down to at least 15 Pa under no-load conditions. A lower number signifies a higher-performing, tighter system.

The Counterintuitive Role of Vacuum in Drying

The goal of freeze drying is sublimation—turning solid ice directly into water vapor. While this requires a vacuum, the process also requires energy in the form of heat. This is where the paradox of vacuum level comes into play.

The Need for Heat Transfer

Sublimation is an energy-intensive process. For the ice within your product to turn into vapor, it must absorb energy from the warmer shelves in the freeze dryer.

How Extreme Vacuum Hinders Drying

This energy transfer relies on conduction. The few remaining gas molecules in the vacuum chamber act as messengers, carrying heat from the shelf to your product.

When you pull an extremely high vacuum (a very low pressure), you remove too many of these gas molecules. This effectively insulates your product from the shelf, starving it of the energy needed for sublimation. The result is a dramatically slower drying time.

Understanding the Trade-offs

The distinction between the system's capability and the process requirement is crucial.

High Ultimate Vacuum: A Good Sign

An empty system that can achieve a very low pressure (a high ultimate vacuum) is a healthy system. This capability gives you the control and precision needed to run an effective drying cycle.

Running at High Vacuum: A Bad Practice

Actually running your product at the machine's ultimate vacuum is a common but critical mistake. It creates a condition of poor heat transfer, which extends drying cycles and reduces overall efficiency. The optimal pressure for drying is always higher than the ultimate vacuum level.

Making the Right Choice for Your Goal

Use your understanding of ultimate vacuum to diagnose your machine and optimize your process separately.

- If your primary focus is diagnosing equipment health: Perform a no-load test. Achieving a low ultimate vacuum (typically below 15 Pa) confirms your pump and seals are in excellent condition.

- If your primary focus is efficient drying: Do not chase the lowest possible pressure. Instead, set a controlled, moderate vacuum level that provides the ideal balance between sublimation and the conductive heat transfer required to drive it.

Ultimately, mastering freeze drying is about using vacuum as a precise tool, not just pursuing its maximum level.

Summary Table:

| Aspect | Role of Ultimate Vacuum | Key Insight |

|---|---|---|

| Definition | Lowest pressure an empty system can achieve | A benchmark for equipment capability, not a process setting. |

| Primary Function | Diagnostic tool for system health | Indicates a strong vacuum pump and airtight seals (e.g., <15 Pa). |

| Process Impact | Not the ideal pressure for drying | Running at ultimate vacuum slows drying by hindering heat transfer. |

| Optimal Use | Perform no-load tests to check equipment | Use a moderate, controlled vacuum level for efficient sublimation. |

Optimize your freeze-drying process with KINTEK's expertise.

Understanding the delicate balance between vacuum level and heat transfer is key to efficient lyophilization. Whether you need a high-performance freeze dryer capable of excellent ultimate vacuum for precise control, or consumables and support to maintain your system's integrity, KINTEK is here to help.

We specialize in providing reliable lab equipment and consumables that ensure your freeze dryer operates at peak diagnostic and processing performance. Let our experts assist you in achieving faster cycle times and superior product quality.

Contact us today to discuss your laboratory's specific needs!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis

- Why is a freeze dryer preferred for reduced graphene oxide (Hh-RGO) powders? Preserve Nano-Structure and Performance

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure

- What is the function of a freeze dryer in the ice-templating process? Preserving Aligned Pore Scaffolds for LAGP