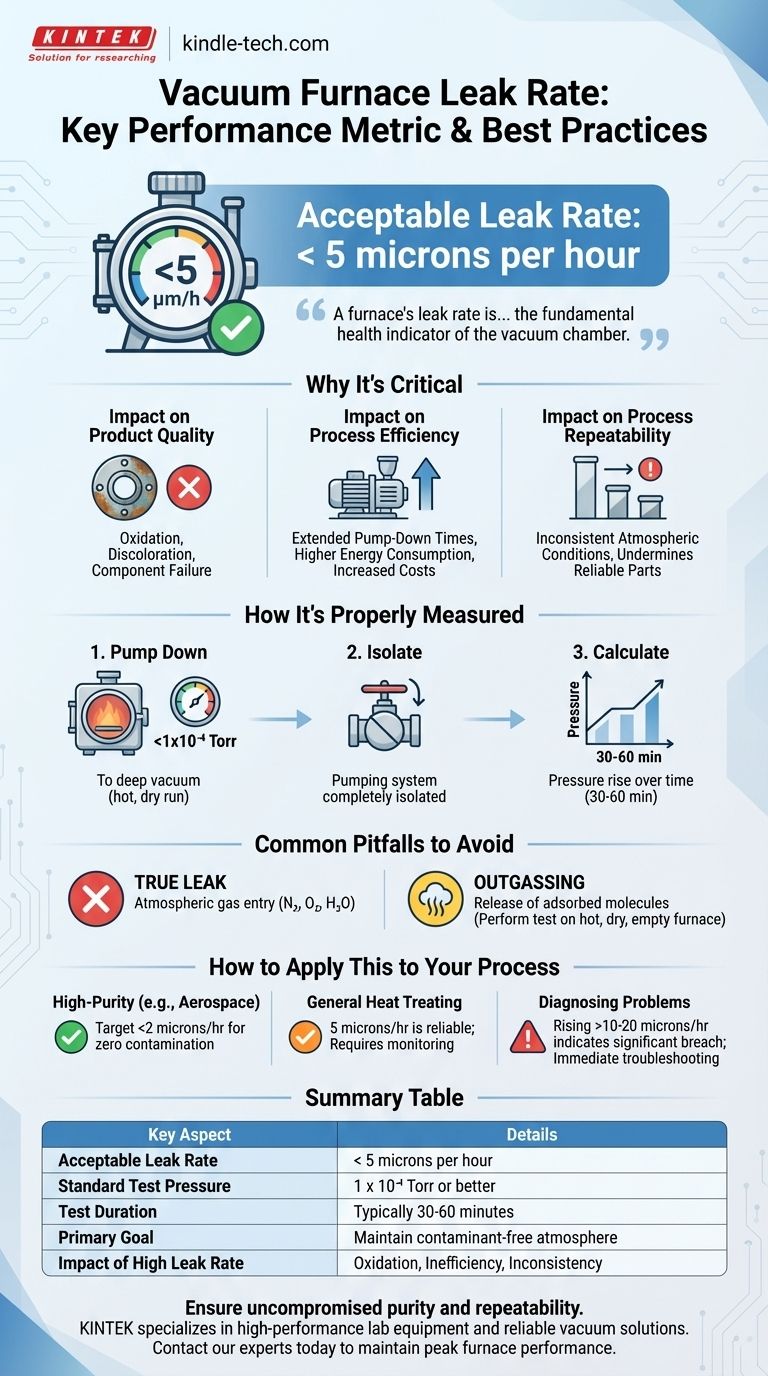

An acceptable leak rate for a high-vacuum furnace is typically less than 5 microns per hour. This specification is a critical benchmark for performance, ensuring the furnace can maintain the required low-pressure environment for a given process. A rate below this level indicates that the vessel is sufficiently sealed to prevent atmospheric contaminants from compromising product quality.

A furnace's leak rate is more than a simple metric; it is the fundamental health indicator of the vacuum chamber. It directly reflects the furnace's ability to create a pure, controlled atmosphere, which is essential for achieving repeatable, high-quality results in sensitive processes like brazing and heat treating.

Why Leak Rate is a Critical Performance Metric

A vacuum furnace is designed to create a controlled environment, free from the reactive gases present in our atmosphere. A leak, no matter how small, works directly against this primary objective.

Impact on Product Quality

The most significant contaminant introduced by a leak is atmospheric air, which consists of nitrogen, oxygen, and water vapor. These elements can cause oxidation, discoloration, and poor metallurgical bonds on the surfaces of parts being processed, leading to component failure.

Impact on Process Efficiency

A leaky furnace forces the high-vacuum pumping system to work continuously to overcome the incoming gas load. This extends pump-down times, increases energy consumption, and puts additional wear on the pumps, raising operational costs.

Impact on Process Repeatability

An inconsistent or unmeasured leak rate makes it impossible to guarantee the same atmospheric conditions from one cycle to the next. This lack of control undermines the ability to produce consistent, reliable parts.

How Leak Rate is Properly Measured

A standardized test ensures that the leak rate measurement is both accurate and repeatable. The procedure is designed to isolate leaks into the chamber from other sources of gas.

The Standard Test Procedure

The test is typically performed immediately after a hot, dry run cycle. The furnace is pumped down to a deep vacuum level, often 1 x 10⁻⁴ Torr or better, to ensure internal surfaces are free of trapped gas and water vapor (outgassed).

The Isolation Phase

Once the ultimate vacuum is reached, the pumping system is completely isolated from the furnace chamber using a main valve. This step is critical; it ensures the test measures only the gas entering the chamber from the outside, not the performance of the pumps themselves.

Calculation and Acceptance

After isolation, the vacuum level is recorded over a set period, typically 30 and 60 minutes. The rise in pressure over this time is calculated to determine the leak rate, which is then compared to the acceptance criterion, such as the common <5 microns/hour standard.

Common Pitfalls to Avoid

Interpreting a leak rate test requires understanding the difference between a true leak and other phenomena that can cause pressure to rise inside the chamber.

Confusing Leaks with Outgassing

Outgassing is the release of molecules (primarily water vapor) that were adsorbed onto the internal surfaces and insulation of the furnace. A pressure rise from outgassing can be mistaken for a leak. This is why a leak test must be performed on a hot, dry, and empty furnace to minimize the effects of outgassing.

Masking Leaks with Pumping Power

A powerful pumping system can sometimes hide the effects of a moderate leak during operation by removing the incoming gas as fast as it enters. However, the contamination is still occurring. The isolation test is the only definitive way to know the true integrity of the chamber.

How to Apply This to Your Process

Your acceptable leak rate depends directly on the sensitivity of your application and your operational goals.

- If your primary focus is high-purity processes (e.g., aerospace brazing): A leak rate below 5 microns/hour is the minimum standard, and a target of less than 2 microns/hour is best practice to ensure zero contamination.

- If your primary focus is general heat treating: The 5 microns/hour standard is a reliable benchmark. Exceeding this slightly may be tolerable, but it requires vigilant monitoring for signs of product oxidation.

- If you are diagnosing a furnace problem: A leak rate rising above 10-20 microns/hour indicates a significant breach that requires immediate troubleshooting, often with a helium leak detector, to find and repair the source.

Ultimately, a disciplined approach to measuring and maintaining a low leak rate is the foundation of reliable and repeatable vacuum furnace operations.

Summary Table:

| Key Aspect | Details |

|---|---|

| Acceptable Leak Rate | < 5 microns per hour |

| Standard Test Pressure | 1 x 10⁻⁴ Torr or better |

| Test Duration | Typically 30-60 minutes |

| Primary Goal | Maintain a contaminant-free, controlled atmosphere |

| Impact of High Leak Rate | Oxidation, process inefficiency, inconsistent results |

Ensure your vacuum furnace delivers uncompromised purity and repeatability.

A controlled, leak-free environment is non-negotiable for sensitive processes like brazing and heat treating. KINTEK specializes in high-performance lab equipment and consumables, providing the reliable vacuum solutions your laboratory needs to protect product quality and maximize efficiency.

Contact our experts today to discuss how we can support your specific application requirements and help you maintain peak furnace performance.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the temperature range of the brazing process? Achieve Perfect Joints with Precise Heat Control

- Can an arc occur in a vacuum? Uncover the Hidden Dangers of High-Voltage Vacuum Systems

- What is the VAR process for steel? Achieve Ultimate Purity and Structural Integrity

- Which furnace removes most air to prevent decarburization? The Definitive Guide to Vacuum Furnaces

- What is the significance of using a solution treatment furnace for 316L cladding? Restore Corrosion Resistance

- Which type of furnace can be used at high temperature? Choose the Right Tool for Your Process

- What is physical vapor transport? A Guide to High-Purity Crystal Growth

- What materials are used in vacuum braze? A Guide to Metals, Alloys, and Filler Selection