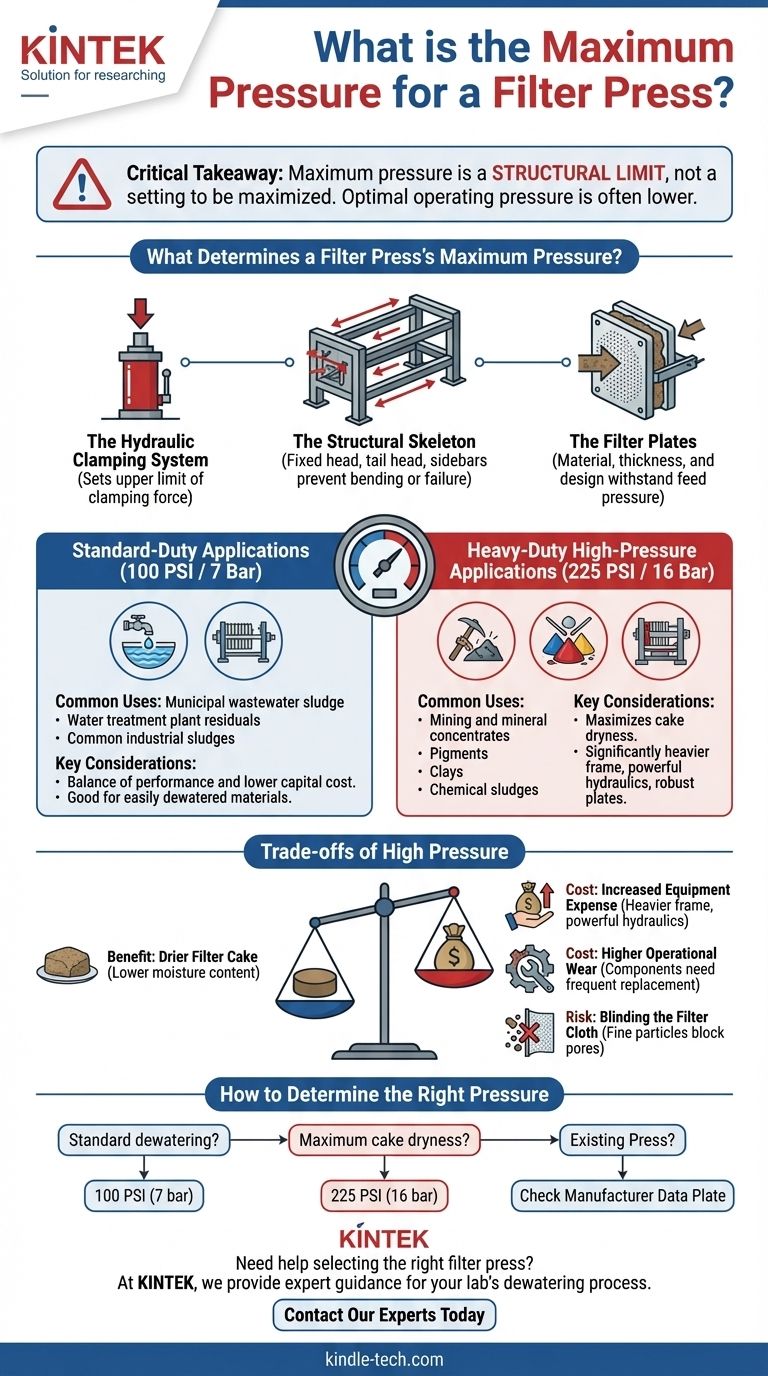

The maximum pressure for a filter press typically falls into one of two categories: 100 PSI (7 bar) for standard-duty applications or 225 PSI (16 bar) for heavy-duty, high-pressure applications. However, this is not a universal figure; the true maximum is a specific engineering limit determined entirely by the design and construction of the individual press.

The critical takeaway is that a filter press's maximum pressure is not a setting to be maximized, but a structural limit that must be respected. The optimal operating pressure is often lower than the maximum and is dictated by your slurry characteristics and process goals.

What Determines a Filter Press's Maximum Pressure?

The maximum pressure rating is a function of the machine's ability to withstand immense forces. Several key components work together to define this limit, and the weakest link determines the system's overall rating.

The Hydraulic Clamping System

The process begins with the hydraulic system. A hydraulic cylinder clamps the stack of filter plates together with a predetermined force, creating a seal. The pressure rating of the hydraulic pump and cylinder sets the upper limit on the clamping force that can be achieved.

The Structural Skeleton

The clamping force generated by the hydraulics is contained by the press's "skeleton." This consists of the fixed head, the movable tail head, and the steel sidebars connecting them. A press rated for 225 PSI will have a significantly heavier and more robust steel frame than one rated for 100 PSI to prevent bending or catastrophic failure under load.

The Filter Plates

The filter plates themselves must be strong enough to withstand the feed pressure of the slurry being pumped into them. The material (polypropylene is the modern standard), thickness, and internal design of the plate dictate its pressure rating. High-pressure plates are heavier and more robustly designed than standard plates.

Standard vs. High-Pressure Applications

The choice between a standard or high-pressure system is driven entirely by the dewatering requirements of the slurry.

Standard Pressure Systems (100 PSI / 7 Bar)

These are the workhorses for a vast range of applications. They are highly effective for materials that dewater relatively easily, such as municipal wastewater sludge, water treatment plant residuals, and many common industrial sludges. They represent a balance between good performance and lower capital cost.

High-Pressure Systems (225 PSI / 16 Bar)

These systems are specified for slurries that are difficult to dewater or when achieving the absolute maximum cake dryness is economically critical. The higher pressure forces more water out of the filter cake. Common applications include mining and mineral concentrates, pigments, clays, and certain chemical sludges where disposal costs are high or the cake is a valuable final product.

Understanding the Trade-offs of High Pressure

Operating at higher pressures involves a series of critical trade-offs that go beyond the initial purchase price.

Benefit: Drier Filter Cake

This is the primary reason to invest in a high-pressure system. By exerting more force on the slurry, you can reduce the final moisture content in the filter cake by several percentage points, which can be significant.

Cost: Increased Equipment Expense

A high-pressure press requires a much heavier frame, more powerful hydraulics, and more robust plates. This results in a substantially higher capital investment compared to a standard-pressure press of the same size.

Cost: Higher Operational Wear

Greater pressure means greater stress. Filter cloths, plate sealing surfaces, and hydraulic components will experience accelerated wear, leading to more frequent replacement and higher lifetime maintenance costs.

Risk: Blinding the Filter Cloth

Applying high feed pressure too quickly can force fine particles deep into the weave of the filter cloth. This condition, known as blinding, blocks the cloth's pores, dramatically reducing filtration efficiency and requiring premature, often difficult, cleaning or replacement.

How to Determine the Right Pressure for Your Application

The maximum design pressure is an engineering limit, but the optimal operating pressure is a process decision.

- If your primary focus is standard dewatering (e.g., municipal sludge): A 100 PSI (7 bar) system typically provides the best balance of cake dryness, cycle time, and operational cost.

- If your primary focus is maximum cake dryness (e.g., mining tailings, valuable concentrates): A 225 PSI (16 bar) high-pressure system is necessary, but you must account for the higher capital and maintenance expenses.

- If you are operating an existing press: The definitive maximum pressure is stated on the manufacturer's data plate and in the operational manual. Never attempt to operate a press beyond this specified limit.

Ultimately, choosing and operating a filter press effectively means matching the equipment's capabilities to your specific process goals and material characteristics.

Summary Table:

| Application Type | Typical Max Pressure | Common Uses | Key Considerations |

|---|---|---|---|

| Standard-Duty | 100 PSI (7 bar) | Municipal sludge, water treatment residuals | Cost-effective, good for easily dewatered materials |

| Heavy-Duty | 225 PSI (16 bar) | Mining concentrates, pigments, difficult sludges | Maximizes cake dryness; higher equipment & maintenance costs |

Need help selecting the right filter press for your specific pressure requirements?

At KINTEK, we specialize in lab equipment and consumables, providing expert guidance to match your laboratory's dewatering process with the ideal filter press. Whether you require a standard 100 PSI system or a heavy-duty 225 PSI solution for maximum cake dryness, our team ensures you get a reliable, efficient, and safe system.

Contact our experts today to discuss your application and receive a personalized recommendation!

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- Are thin films used as coatings on lenses? The Key to Superior Optical Performance

- Is natural or synthetic graphite better? Choosing the Right Material for Your Application

- What is the difference between an industrial furnace and a laboratory electric furnace? Choose the Right Heating System

- What temperature is approximately equal to sintering? A Guide Based on Your Material's Melting Point

- What are the types of annealing? Choose the Right Process for Your Metal's Properties

- Why graphite Cannot conduct electricity? Unlocking the Secret of its High Electrical Conductivity

- What is the function of high-temperature thermal treatment equipment in TiO2/G nanocomposites? Optimize Photocatalysts

- What is the main advantage of annealing? Restore Ductility and Relieve Internal Stress for Better Workability