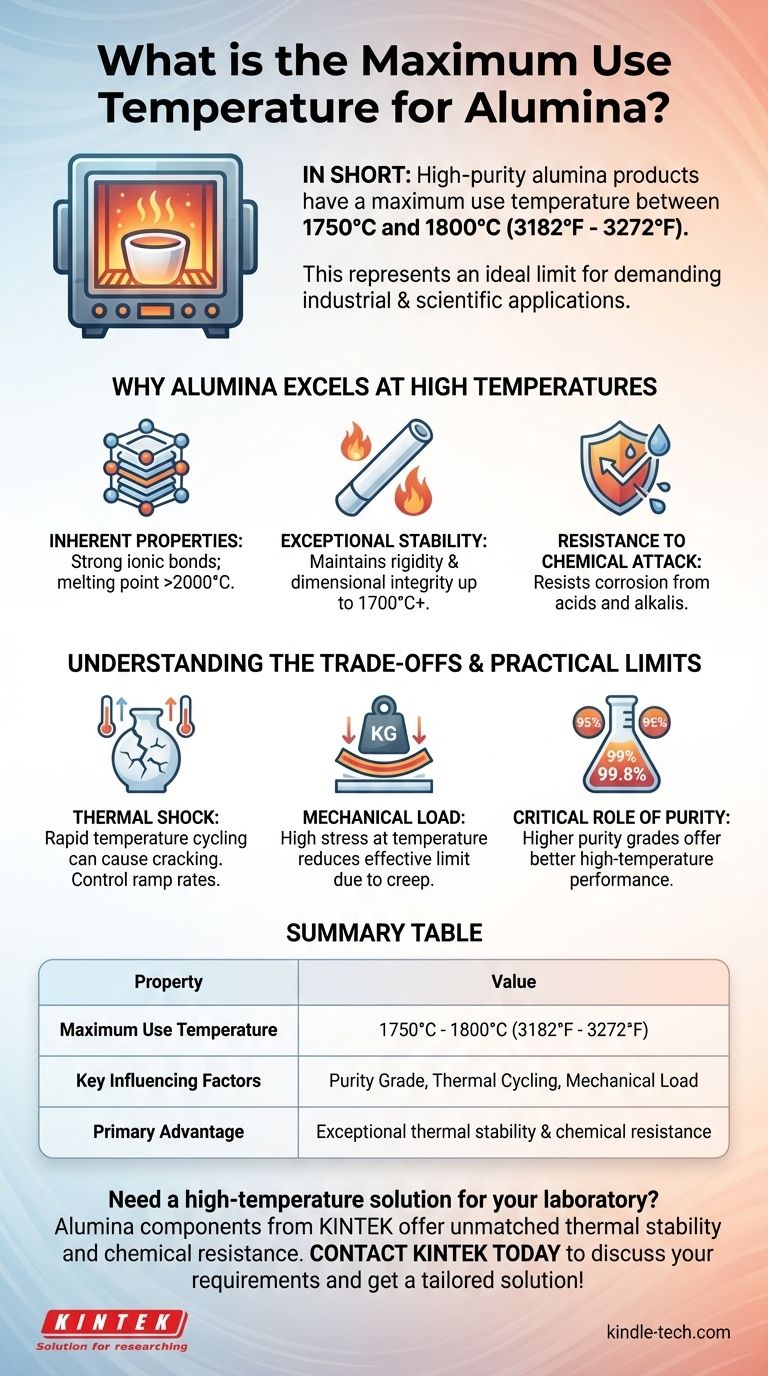

In short, high-purity alumina products have a maximum use temperature between 1750°C and 1800°C (3182°F - 3272°F). This remarkable thermal stability makes it a default choice for many demanding industrial and scientific applications, from furnace components to high-tech manufacturing. However, this number represents an ideal limit, not a universal guarantee.

The true value of alumina isn't just its high-temperature tolerance but its ability to maintain structural integrity and chemical resistance under extreme heat. The practical temperature limit for your specific application will depend heavily on factors like thermal cycling, mechanical load, and chemical environment.

Why Alumina Excels at High Temperatures

Alumina, or aluminum oxide (Al₂O₃), is not simply a material that resists melting. Its performance at high temperatures is a result of its fundamental atomic structure and resulting physical properties.

Inherent Material Properties

The melting point of pure alumina is over 2000°C. Its maximum use temperature is lower but is still exceptionally high due to the strong ionic bonds between aluminum and oxygen atoms, which require immense thermal energy to disrupt.

Exceptional Thermal Stability

Unlike metals that soften significantly as they approach their melting point, alumina remains rigid and dimensionally stable. This ensures that components like tubes, rods, and insulators maintain their precise shape and function even when heated to over 1700°C.

Resistance to Chemical Attack

High temperatures accelerate corrosion and chemical reactions. Alumina is highly resistant to both acids and alkalis, preventing degradation and contamination in aggressive environments, such as inside an electric furnace or in chemical processing.

Understanding the Trade-offs and Practical Limits

While the 1800°C figure is impressive, it's critical to understand the real-world conditions that can reduce the effective service temperature. An expert selects a material based on its performance under stress, not just its datasheet limits.

The Impact of Thermal Shock

Thermal shock occurs when a material is heated or cooled too rapidly, causing internal stresses that can lead to cracks and catastrophic failure.

While alumina has good thermal shock resistance for a ceramic, it is still a brittle material. Rapid temperature cycling is one of the most common causes of failure in alumina components.

Mechanical Load at Temperature

The maximum use temperature assumes minimal mechanical stress. If an alumina component must bear a significant load, its effective temperature limit will be lower due to a phenomenon called creep, where the material slowly deforms over time.

The Critical Role of Purity

Commercial alumina comes in various purity grades (e.g., 95%, 99%, 99.8%). Higher purity grades generally have a higher maximum service temperature and better overall performance, as impurities can create weak points in the ceramic's structure.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to the primary demands of your task. Consider your goal to determine if alumina is the optimal choice.

- If your primary focus is maximum temperature in a stable, controlled environment: Alumina is an excellent choice, capable of performing reliably up to 1750-1800°C.

- If your application involves rapid heating and cooling cycles: You must carefully control ramp rates or consider a material with superior thermal shock resistance, like boron nitride or silicon carbide.

- If the component must withstand high mechanical stress at temperature: You must de-rate the maximum use temperature or investigate advanced ceramics designed specifically for high-temperature structural applications.

Ultimately, understanding these trade-offs is key to leveraging alumina's incredible thermal properties for a long and reliable service life.

Summary Table:

| Property | Value |

|---|---|

| Maximum Use Temperature | 1750°C - 1800°C (3182°F - 3272°F) |

| Key Influencing Factors | Purity Grade, Thermal Cycling, Mechanical Load |

| Primary Advantage | Exceptional thermal stability & chemical resistance |

Need a high-temperature solution for your laboratory?

Alumina components from KINTEK offer unmatched thermal stability and chemical resistance, making them ideal for furnace linings, tubes, and crucibles that must withstand extreme conditions. Our experts can help you select the right grade of alumina or other advanced ceramics to ensure reliability and longevity in your specific application.

Contact KINTEK today to discuss your high-temperature requirements and get a tailored solution!

Visual Guide

Related Products

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Electrode Polishing Material for Electrochemical Experiments

- Conductive Carbon Cloth Carbon Paper Carbon Felt for Electrodes and Batteries

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- How does Alumina (Al2O3) ceramic coating influence CdS tribocatalytic activity? Boost Degradation Rates by 6X

- What are the properties of ceramic surfaces? Discover Their Extreme Hardness and Stability

- What happens to a ceramic material when it is sintered? The Transformation from Powder to Dense Solid

- What type of structure is silicon carbide? A Covalent Network Solid for Extreme Performance

- What metrics were used to evaluate the grinding process of the composite ceramic (AlSiTi)? Optimize Your Grinding Result

- How does sintering affect density? Achieve Precise Control Over Material Properties

- What is the purpose of using ceramic fiber insulation in molten salt pipelines? Ensure Fluidity and Energy Efficiency

- What is the sintering temperature of ceramic? Master the Thermal Journey for Durable Results