Sputter deposition is a physical vapor deposition (PVD) process that uses momentum transfer to create a thin film. In a high-vacuum chamber, energetic ions from a plasma bombard a source material, known as the target. This collision physically ejects or "sputters" atoms from the target, which then travel and deposit onto a substrate, forming a highly uniform and adherent coating.

Sputtering is not a chemical or thermal process; it is a mechanical one at the atomic scale. The core mechanism relies on accelerating ions to physically knock atoms off a source material, giving engineers precise control over the growth of materials that are otherwise difficult to deposit.

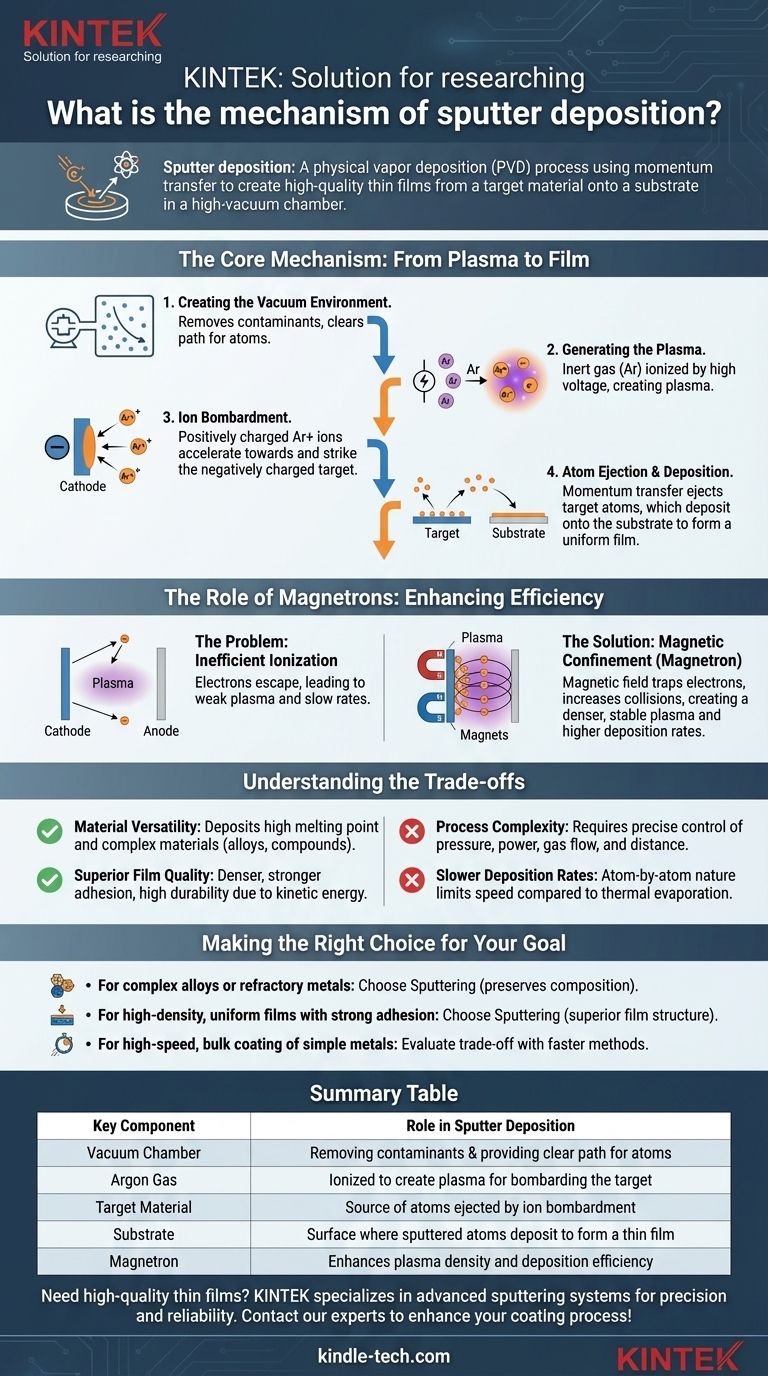

The Core Mechanism: From Plasma to Film

Sputtering is a sequential process that takes place inside a highly controlled vacuum chamber. Each step is critical for achieving a high-quality thin film.

Step 1: Creating the Vacuum Environment

Before deposition begins, the chamber is pumped down to a high vacuum. This serves two crucial purposes: removing contaminants like oxygen and water vapor that could react with the film, and clearing a path for the sputtered atoms to travel from the target to the substrate without colliding with other gas molecules.

Step 2: Generating the Plasma

A small, controlled amount of an inert gas, almost always argon (Ar), is introduced into the chamber. A high voltage is then applied between two electrodes: the cathode (which holds the target material) and the anode (which holds the substrate). This strong electric field energizes the argon gas, stripping electrons from the argon atoms and creating a glowing, ionized gas known as a plasma.

This plasma is a dynamic soup of positively charged argon ions (Ar+), free electrons, and neutral argon atoms.

Step 3: Ion Bombardment

The target material is held at a strong negative voltage (the cathode). The positively charged argon ions (Ar+) in the plasma are naturally and powerfully accelerated toward this negatively charged target.

They strike the target surface with significant kinetic energy.

Step 4: Atom Ejection and Deposition

The impact of an argon ion is a pure momentum transfer event, like a cue ball striking a rack of billiard balls. This collision dislodges or "sputters" atoms from the surface of the target material.

These ejected target atoms travel through the vacuum chamber and land on the substrate, gradually building up, atom by atom, into a thin, dense, and uniform film.

The Role of Magnetrons: Enhancing Efficiency

Most modern sputtering systems are magnetron sputtering systems. The addition of magnets dramatically improves the efficiency and stability of the process.

The Problem: Inefficient Ionization

In a simple DC sputtering system, the free electrons in the plasma are quickly attracted to the grounded anode and lost. This limits the number of ion-creating collisions and results in a weak plasma that requires higher pressures and delivers slow deposition rates.

The Solution: Magnetic Confinement

In magnetron sputtering, a powerful magnetic field is placed behind the target. This field is perpendicular to the electric field, forcing the highly mobile electrons into a long, spiral path directly in front of the target surface.

The Result: A Denser, More Stable Plasma

By trapping the electrons near the target, their path length is increased by orders of magnitude. This drastically increases the probability that they will collide with and ionize neutral argon atoms.

The result is a much denser, self-sustaining plasma that can be maintained at lower pressures. This leads to higher deposition rates and less gas incorporation into the growing film, producing a purer final coating.

Understanding the Trade-offs

While powerful, sputtering is a complex process with distinct advantages and disadvantages that make it suitable for specific applications.

Advantage: Material Versatility

Because sputtering is a physical, not thermal, process, it excels at depositing materials with extremely high melting points (like tungsten or tantalum) and complex materials like alloys or compounds. The composition of the sputtered film is very close to the composition of the target.

Advantage: Superior Film Quality

The kinetic energy of the sputtered atoms as they impact the substrate results in films that are typically much denser and have stronger adhesion than those produced by thermal evaporation. This makes sputtered films highly durable.

Disadvantage: Process Complexity

Sputtering has numerous control parameters, including pressure, power, gas flow, and target-to-substrate distance. While this complexity gives experts fine-grained control over film microstructure, it also makes the process more difficult to manage than simpler methods.

Disadvantage: Slower Deposition Rates

Compared to a high-rate process like thermal evaporation, sputtering is generally slower. The one-atom-at-a-time nature of the ejection process limits the overall speed, making it less ideal for thick, bulk coatings where quality is secondary to speed.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on the material you are using and the film properties you need to achieve.

- If your primary focus is depositing complex alloys or refractory metals: Sputtering is the ideal choice due to its physical, non-thermal nature that preserves material composition.

- If your primary focus is achieving high-density, uniform films with strong adhesion: The momentum transfer inherent in sputtering provides a superior film structure for demanding applications.

- If your primary focus is high-speed, bulk coating of simple metals: You may need to evaluate the trade-off between sputtering's quality and the faster rates of other methods like thermal evaporation.

Ultimately, sputtering provides unparalleled control and quality for producing the high-performance thin films that drive modern technology.

Summary Table:

| Key Component | Role in Sputter Deposition |

|---|---|

| Vacuum Chamber | Removes contaminants and provides a clear path for atoms |

| Argon Gas | Ionized to create plasma for bombarding the target |

| Target Material | Source of atoms ejected by ion bombardment |

| Substrate | Surface where sputtered atoms deposit to form a thin film |

| Magnetron | Enhances plasma density and deposition efficiency |

Need high-quality thin films for your research or production? KINTEK specializes in advanced sputtering systems and lab equipment designed for precision and reliability. Whether you're working with complex alloys, refractory metals, or require superior film adhesion, our solutions deliver the control and consistency your lab demands. Contact our experts today to discuss how our sputtering technology can enhance your coating process!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

People Also Ask

- What are the techniques for thin film deposition? Choose the Right Method for Your Application

- What is the process of HDP CVD? Mastering Void-Free Gap-Fill for Semiconductor Manufacturing

- Which gas serves as carrier gas in CVD graphene synthesis? Mastering H₂ and Ar for Superior Quality

- What is the role of a CVD system in silicon microwire fabrication? Mastering VLS Growth for Precision Arrays

- Which is an example of chemical vapour deposition? The CVD Process for High-Performance Materials

- What is the role of CVD equipment in h-BN anti-corrosion coatings? Engineering Atomic-Level Metal Protection

- What is the mechanism of CVD graphene? Mastering the Process for High-Quality, Large-Area Films

- Which is better CVD or Hpht? Choose the Right Lab-Grown Diamond for Your Needs