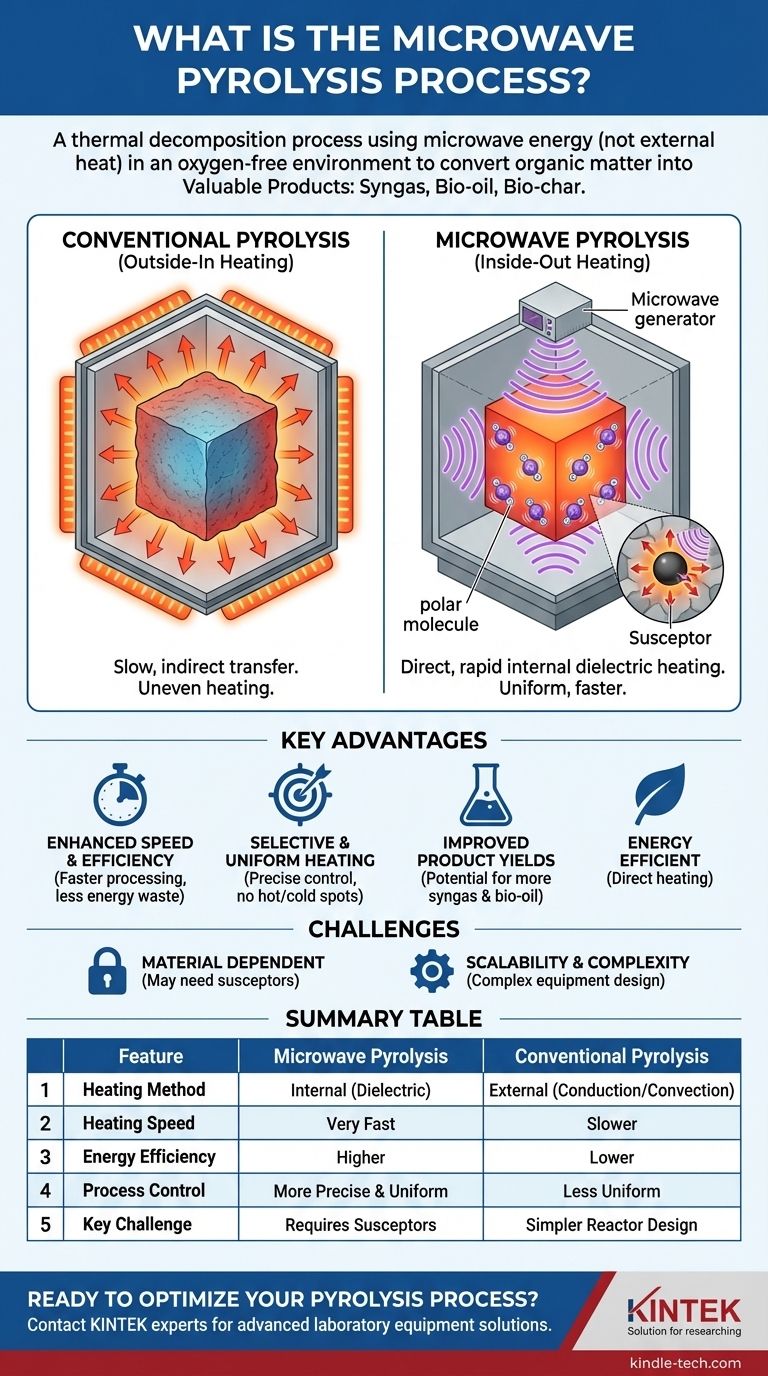

At its core, microwave pyrolysis is a thermal decomposition process that uses microwave energy, rather than conventional external heating, to break down materials in an oxygen-free environment. This advanced method converts organic matter, such as biomass, plastics, or tires, into valuable products like syngas (synthesis gas), bio-oil (a liquid fuel), and bio-char (a solid carbon-rich material).

The fundamental difference between microwave and conventional pyrolysis lies in the heating method. Instead of heating a chamber from the outside-in, microwaves directly and rapidly heat the material from the inside-out, leading to faster processing and potentially higher energy efficiency.

How Microwave Heating Changes the Pyrolysis Equation

To understand microwave pyrolysis, you must first understand that it is not just a different power source; it is a fundamentally different heating mechanism that changes the entire process dynamic.

The Principle of Dielectric Heating

Traditional pyrolysis relies on conduction and convection, where external heating elements heat the walls of a furnace, which then slowly transfers that heat to the material inside.

Microwave pyrolysis uses dielectric heating. The microwaves cause polar molecules within the material to rapidly vibrate and rotate, generating friction and thus, heat, directly inside the material itself.

The Role of Microwave Susceptors

Not all materials absorb microwave energy effectively. For substances with low dielectric properties (like many dry plastics), a microwave susceptor is required.

A susceptor is a highly microwave-absorbent material, such as activated carbon or silicon carbide, that is mixed with the primary feedstock. The susceptor absorbs the microwave energy, converts it to intense thermal energy, and transfers that heat directly to the surrounding material.

From Outside-In to Inside-Out Heating

This "inside-out" heating model is the primary advantage of the microwave approach. It avoids the slow thermal transfer of conventional methods, creating a more uniform and rapid temperature rise throughout the entire volume of the material.

Key Advantages of the Microwave Approach

The unique heating mechanism of microwave pyrolysis offers several distinct operational advantages over its conventional counterpart.

Enhanced Speed and Efficiency

Because the material heats itself directly, the process is significantly faster. There is less wasted energy heating the reactor vessel and surrounding environment, leading to higher overall energy efficiency.

Selective and Uniform Heating

Microwaves can be targeted to heat only the feedstock (and susceptor), not the entire chamber. This results in highly responsive and precise temperature control, ensuring the material is heated uniformly and avoiding hot or cold spots that can lower product quality.

Potentially Improved Product Yields

The rapid and uniform heating profile can alter the chemical reaction pathways. For many feedstocks, this leads to a higher yield of valuable outputs, particularly the gas (syngas) and liquid (bio-oil) fractions, compared to the slower heating rates of conventional pyrolysis.

Understanding the Trade-offs and Challenges

Despite its advantages, microwave pyrolysis is not a universal solution. It comes with its own set of engineering challenges and limitations that must be considered.

Material-Dependent Performance

The process is highly dependent on the feedstock's dielectric properties. Materials that do not absorb microwaves well will not heat effectively without the addition of a susceptor, adding a step to the process.

The Need for Susceptors

While effective, adding a susceptor can introduce complications. It can increase operational costs and, if not separated post-pyrolysis, can contaminate the final bio-char product, potentially reducing its value.

Scalability and Equipment Complexity

Designing large-scale industrial microwave pyrolysis systems is complex. It requires specialized microwave generators, waveguides, and applicator cavities to ensure uniform energy distribution. Furthermore, as noted in similar high-temperature microwave applications, cooling the equipment can become a significant engineering hurdle.

Making the Right Choice for Your Application

Choosing between conventional and microwave pyrolysis depends entirely on your specific goals, feedstock, and operational priorities.

- If your primary focus is rapid processing and energy efficiency: Microwave pyrolysis is a compelling option due to its direct and fast internal heating mechanism.

- If your primary focus is simplicity and handling diverse feedstocks without additives: Conventional pyrolysis often offers a more robust and straightforward setup that is less sensitive to material properties.

- If your primary focus is maximizing the yield of high-quality liquid or gas products: The precise, uniform temperature control of microwave pyrolysis may provide superior results and a more valuable product distribution.

Understanding this fundamental difference in heating is the key to selecting the right technology to achieve your waste-to-value objectives.

Summary Table:

| Feature | Microwave Pyrolysis | Conventional Pyrolysis |

|---|---|---|

| Heating Method | Internal (dielectric heating) | External (conduction/convection) |

| Heating Speed | Very Fast | Slower |

| Energy Efficiency | Higher | Lower |

| Process Control | More Precise & Uniform | Less Uniform |

| Key Challenge | Requires susceptors for some materials | Simpler reactor design |

Ready to optimize your pyrolysis process?

At KINTEK, we specialize in advanced laboratory equipment for cutting-edge thermal processes like microwave pyrolysis. Our expertise can help you select the right technology to maximize your yield of syngas, bio-oil, and bio-char from your specific feedstock.

Contact our experts today to discuss how our solutions can enhance your waste-to-energy or chemical production research.

Get in touch via our Contact Form

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

People Also Ask

- Is plastic pyrolysis eco friendly? A Deep Dive into the Environmental Trade-offs

- What is the thermal regeneration of activated carbon? Restore Performance & Cut Costs

- What is the temperature of carbon reactivation? Optimize Your Process Between 700°C and 900°C

- How does the rotational frequency of a graphite drum influence aluminum bronze castings? Master SHS Process Precision

- What is a fluidized bed chemical reaction? A Guide to Superior Heat Transfer & Continuous Processing

- What is biochar obtained from the pyrolysis? A Key Product of Biomass Conversion

- What is the pyrolysis reaction of biomass? A Guide to Converting Waste into Valuable Biochar, Bio-oil, and Syngas

- What is the difference between regeneration and reactivation of carbon? Clarifying Key Terminology