To maintain carbon felt in flow batteries, a monthly chemical regeneration is recommended. This procedure involves flushing the felt with a 5% hydrogen peroxide (H₂O₂) solution, allowing it to sit for approximately two hours to dissolve organic blockages, followed by a thorough rinse with deionized water and drying with an inert gas like nitrogen.

This maintenance is not an electrical "deep cycle," but a chemical cleaning protocol designed to restore the felt's performance by removing contaminants that block the electrode's active surface area and impede electrolyte flow.

The Role of Carbon Felt in Flow Batteries

Carbon felt serves as the porous electrode in a flow battery, a critical component where the electrochemical energy conversion takes place. Its performance is directly tied to its physical properties.

The Importance of Porosity and Surface Area

The felt's high porosity allows the liquid electrolyte to flow through it with minimal pressure drop. Its vast microscopic surface area provides the necessary sites for the electrochemical reactions (reduction and oxidation) to occur efficiently.

Direct Impact on Battery Performance

The condition of the carbon felt directly dictates the battery's power density and overall efficiency. A clean, unobstructed felt ensures that the maximum amount of electrolyte is reacting at any given moment, enabling the battery to deliver its designed performance.

Why Maintenance is Critical: The Problem of Fouling

Over time, the performance of carbon felt degrades due to a process known as fouling or clogging. This is the core issue that monthly maintenance aims to solve.

The Source of Contaminants

Fouling is caused by the accumulation of unwanted materials within the felt's porous structure. These "organic blockages" can originate from side reactions, gradual degradation of electrolyte components, or impurities introduced into the system.

How Fouling Degrades Performance

These contaminants physically block the pores of the felt. This blockage restricts electrolyte flow, leading to an increased pressure drop across the stack, and masks the active sites on the carbon fibers, reducing the available surface area for reaction. The result is a noticeable drop in power output and energy efficiency.

The Chemical Regeneration Protocol: A Step-by-Step Analysis

The recommended procedure is a targeted chemical attack on the organic foulants that accumulate in the electrode.

Step 1: 5% H₂O₂ Injection (Oxidation)

Hydrogen peroxide (H₂O₂) is a strong oxidizing agent. When introduced into the system, it chemically breaks down the complex organic molecules clogging the felt into simpler, soluble substances that can be easily flushed away. The 5% concentration is chosen as a balance between being effective enough to clean the felt and mild enough to minimize damage to the carbon fibers themselves.

Step 2: Dwell Time (Reaction)

Letting the solution sit for approximately two hours provides the necessary time for the H₂O₂ to penetrate deep into the porous felt structure and fully react with the contaminants.

Step 3: Water Wash (Rinsing)

After the reaction period, the system is flushed thoroughly with deionized (DI) water. This step is critical for removing both the broken-down contaminants and any residual hydrogen peroxide, which could cause unwanted side reactions if left in the system.

Step 4: Nitrogen Drying (Inert Preparation)

Finally, the felt is dried using dry nitrogen gas. Using an inert gas is crucial because it removes moisture without introducing oxygen or other reactive atmospheric components that could contaminate the electrolyte or compromise the system's electrochemical stability upon restart.

Understanding the Trade-offs and Risks

While effective, this maintenance procedure is not without risks and must be implemented with care.

The Risk of Over-Oxidation

Hydrogen peroxide is aggressive. If the concentration is too high, the dwell time is too long, or the frequency of cleaning is excessive, the H₂O₂ can begin to oxidize the carbon felt itself. This damages the electrode, potentially reducing its structural integrity and electrical conductivity over the long term.

The Misnomer of a "Deep Cycle"

It is critical to distinguish this chemical cleaning from an electrical deep cycle (a full discharge and recharge). An electrical deep cycle is sometimes used to rebalance the state-of-charge between cells but does nothing to remove physical, organic blockages. Confusing the two can lead to improper maintenance and unresolved performance issues.

Manufacturer and Chemistry-Specific Needs

This procedure is a general guideline. Always prioritize the specific maintenance protocols provided by the battery manufacturer. Different electrolyte chemistries (e.g., Vanadium, Zinc-Bromine) may have unique degradation pathways requiring different cleaning agents or procedures.

How to Apply This to Your System

Base your maintenance strategy on measured performance indicators, not just the calendar.

- If your primary focus is routine preventative maintenance: Implement this procedure on a set schedule, but track key metrics like pressure drop and cell resistance. A significant rise in these indicators is a clear signal that cleaning is required.

- If you are diagnosing a sudden performance drop: This chemical regeneration is a primary troubleshooting step to rule out or correct electrode fouling as the cause of the problem.

- If you are developing a new flow battery system: Use this protocol as a starting point. Validate its effectiveness and assess any potential damage to your specific carbon felt material through controlled experiments.

Properly maintaining the carbon felt electrode is fundamental to ensuring the long-term reliability and performance of your flow battery system.

Summary Table:

| Maintenance Step | Purpose | Key Details |

|---|---|---|

| 1. H₂O₂ Injection | Oxidize and break down organic blockages | Use a 5% hydrogen peroxide solution. |

| 2. Dwell Time | Allow for complete chemical reaction | Let the solution sit for approximately 2 hours. |

| 3. Water Wash | Rinse away contaminants and residual H₂O₂ | Flush thoroughly with deionized (DI) water. |

| 4. Nitrogen Drying | Prepare the system for operation | Dry with inert nitrogen gas to prevent contamination. |

Maximize the lifespan and performance of your flow battery system. Proper maintenance of critical components like carbon felt electrodes is key to operational efficiency. KINTEK specializes in high-quality lab equipment and consumables for advanced energy storage applications. Our experts can help you select the right materials and develop optimal maintenance protocols for your specific needs.

Contact our team today to discuss how we can support your laboratory's flow battery research and maintenance goals.

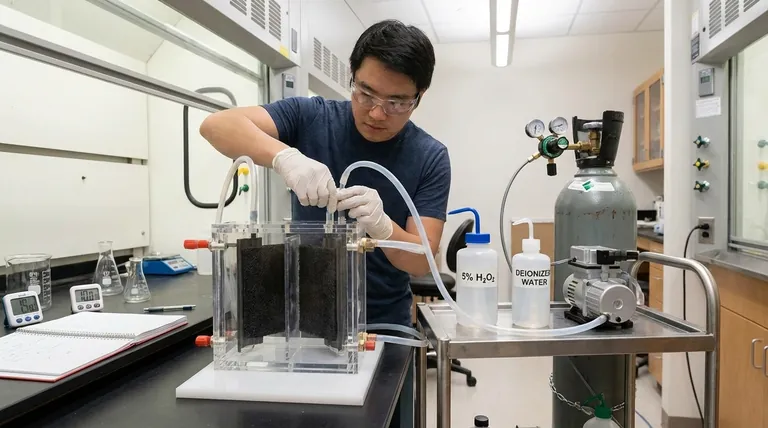

Visual Guide

Related Products

- Glassy Carbon Electrochemical Electrode

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Aluminum Foil Current Collector for Lithium Battery

- Gold Disc Electrode

People Also Ask

- How should carbon paper be handled during cutting? Prevent Fractures with a Delicate, Precise Approach

- What are the advantages of using a vacuum drying oven for silver-carbon films? Enhance Conductivity and Density

- What is the synthesis method of graphene? Top-Down vs. Bottom-Up Approaches for Your Application

- How does high-temperature heating contribute to the performance of Pt/FTO cathodes? Unlock Maximum DSSC Efficiency

- What is the role of a laboratory coin cell crimping machine? Precision Sealing for Solid-State Battery Success

- Why evaluate high-nickel cathode thermal safety with high-sensitivity gas analysis? Ensure Battery Stability.

- What precautions should be taken when cutting carbon cloth? Avoid Short Circuits and Ensure Device Safety

- In which fields is nickel foam widely used? A Key Material for Advanced Engineering