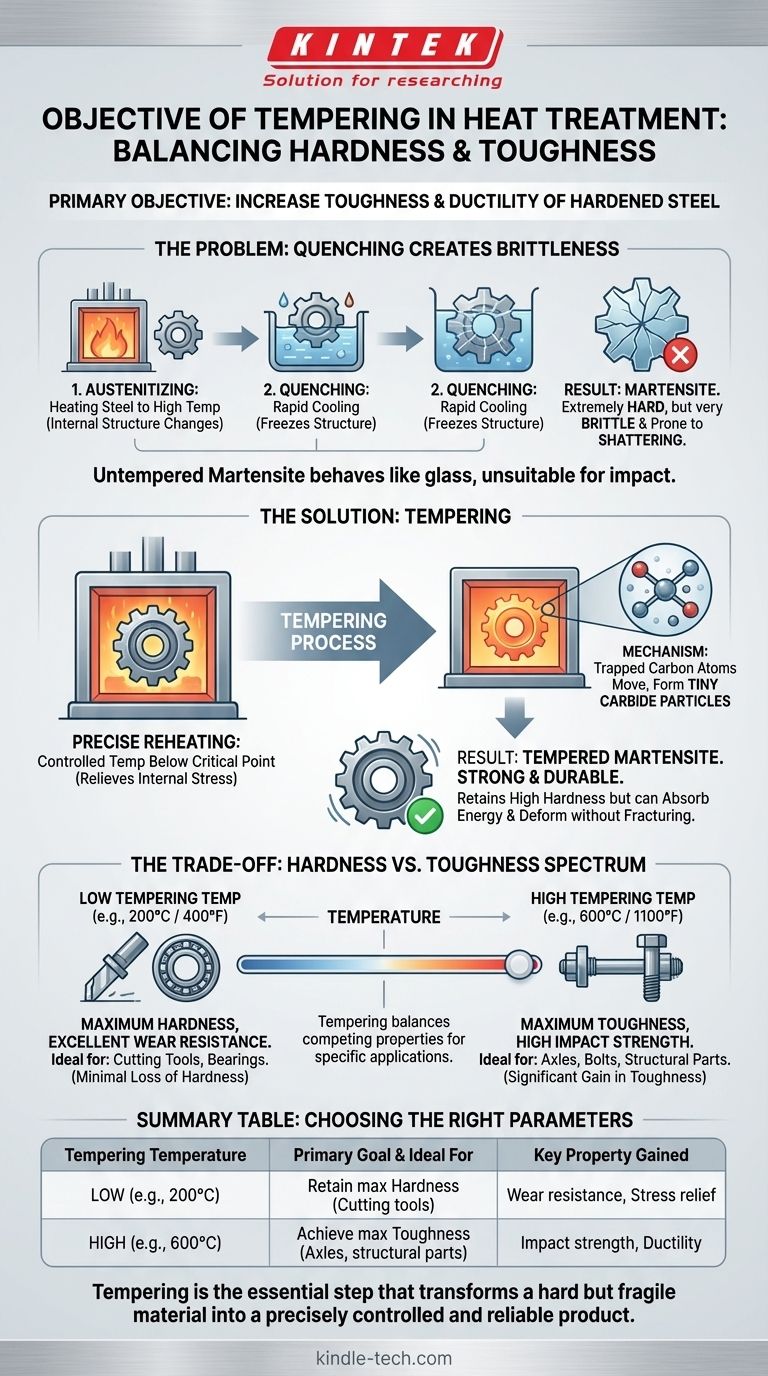

The primary objective of tempering is to increase the toughness and ductility of a hardened metal, especially steel. After a process called quenching makes steel extremely hard, it also becomes very brittle and prone to shattering. Tempering is the crucial follow-up step that reduces this brittleness, creating a more durable and resilient final product.

After hardening steel to its maximum strength, it is often too brittle for practical use. Tempering is the controlled process of trading a small amount of that peak hardness for a significant and necessary gain in toughness, preventing catastrophic failure under stress.

The Problem: Why Hardened Steel Needs Tempering

To understand tempering, you must first understand the process that precedes it: quenching. These two procedures work together to achieve specific mechanical properties that neither can accomplish alone.

The Quenching Process and Martensite

The journey begins by heating steel to a very high temperature (a process called austenitizing), where its internal crystal structure changes. If the steel is then cooled very rapidly—or quenched—in a medium like water or oil, this new structure is frozen in place.

This new, ultra-hard microstructure is called martensite. It is incredibly strong and hard due to the immense internal stresses created by trapping carbon atoms within the iron crystals.

The Brittleness of Martensite

While martensite provides exceptional hardness and wear resistance, it comes at a steep price: extreme brittleness. A part made of untempered martensitic steel behaves much like glass. It can withstand immense compressive force but will shatter suddenly if subjected to a sharp impact or bending force.

This makes the material unsuitable for most real-world applications, from automotive components to tools, where some degree of flex and impact resistance is essential.

How Tempering Solves the Problem

Tempering is a precise reheating process designed to relieve the internal stresses locked inside the martensitic structure, transforming the brittle material into a tough, usable one.

The Tempering Mechanism

After quenching, the hardened part is reheated to a specific temperature, always below the critical temperature used for the initial hardening. It is held at this tempering temperature for a set amount of time and then allowed to cool.

This controlled heating gives the trapped carbon atoms just enough energy to move slightly and form tiny, well-dispersed particles of a compound called carbide.

The Resulting Properties

This micro-level change has a profound effect on the material's macro properties. Relieving the internal stresses and forming these carbide precipitates significantly increases the steel's toughness and ductility.

The final structure, known as tempered martensite, is no longer prone to shattering. It retains a high degree of hardness and strength but can now absorb energy and deform slightly under load without fracturing.

Understanding the Trade-offs

Tempering is not a one-size-fits-all process. It is a tool for achieving a precise balance between two competing properties: hardness and toughness.

The Hardness vs. Toughness Spectrum

There is a direct and predictable trade-off controlled by the tempering temperature.

- Low Tempering Temperatures (e.g., 200°C / 400°F): Result in a minimal loss of hardness, retaining excellent wear resistance while adding just enough toughness to prevent chipping. This is ideal for cutting tools.

- High Tempering Temperatures (e.g., 600°C / 1100°F): Result in a significant reduction in hardness but a massive gain in toughness and ductility. This is perfect for structural components like axles or bolts that must withstand high impacts.

Tempering vs. Other Treatments

It is critical not to confuse tempering with other heat treatments. For example, annealing also involves heating a metal, but its goal is to achieve maximum softness and machinability, effectively erasing the effects of hardening. Tempering, in contrast, refines the properties created by hardening.

Making the Right Choice for Your Goal

The decision to temper and the specific parameters used are dictated entirely by the component's intended application.

- If your primary focus is maximum wear resistance and edge retention: Use quenching followed by a low-temperature temper to relieve stress without sacrificing significant hardness.

- If your primary focus is high impact strength and durability: Use quenching followed by a high-temperature temper to achieve the best possible toughness, even at the cost of some hardness.

- If your primary focus is making the metal as soft as possible for forming or machining: Annealing is the correct process, not quenching and tempering.

Ultimately, tempering is the essential engineering step that transforms a hard but fragile material into one with a precisely controlled and reliable balance of strength and durability.

Summary Table:

| Tempering Temperature | Primary Goal | Ideal For | Key Property Gained |

|---|---|---|---|

| Low (e.g., 200°C / 400°F) | Retain maximum hardness | Cutting tools, bearings | Wear resistance, stress relief |

| High (e.g., 600°C / 1100°F) | Achieve maximum toughness | Axles, bolts, structural parts | Impact strength, ductility |

Ready to achieve the perfect material properties for your components?

At KINTEK, we specialize in providing the precise lab equipment and consumables needed for controlled heat treatment processes like tempering. Whether you are developing cutting-edge tools or durable structural parts, our solutions help you achieve the critical balance between hardness and toughness.

Contact our experts today to discuss how we can support your laboratory's heat treatment needs and ensure your materials meet the highest standards of performance and reliability.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the difference between a tubular furnace and a muffle furnace? Choose the Right Tool for Your Application

- What is the role of a high-temperature box furnace in 9Cr-1Mo steel normalizing? Achieve Precise Microstructure Control

- What affects ash content? Uncover the Key Factors in Material Analysis

- What is a sintering furnace? The Precision Tool for Transforming Powder into Dense, Strong Parts

- How do the requirements for temperature control in sintering equipment affect Cu-Al2O3 internal oxidation at 950°C?

- What kind of environment does a muffle furnace provide for Ca3Co4O9 sintering? Achieve Stable Oxidation for Materials

- What are the primary applications of muffle and tube furnaces in photocatalysts? Optimize Metal Loading & Support Synthesis

- What is the power rating of a muffle furnace? Choose the Right Voltage & Power for Your Lab