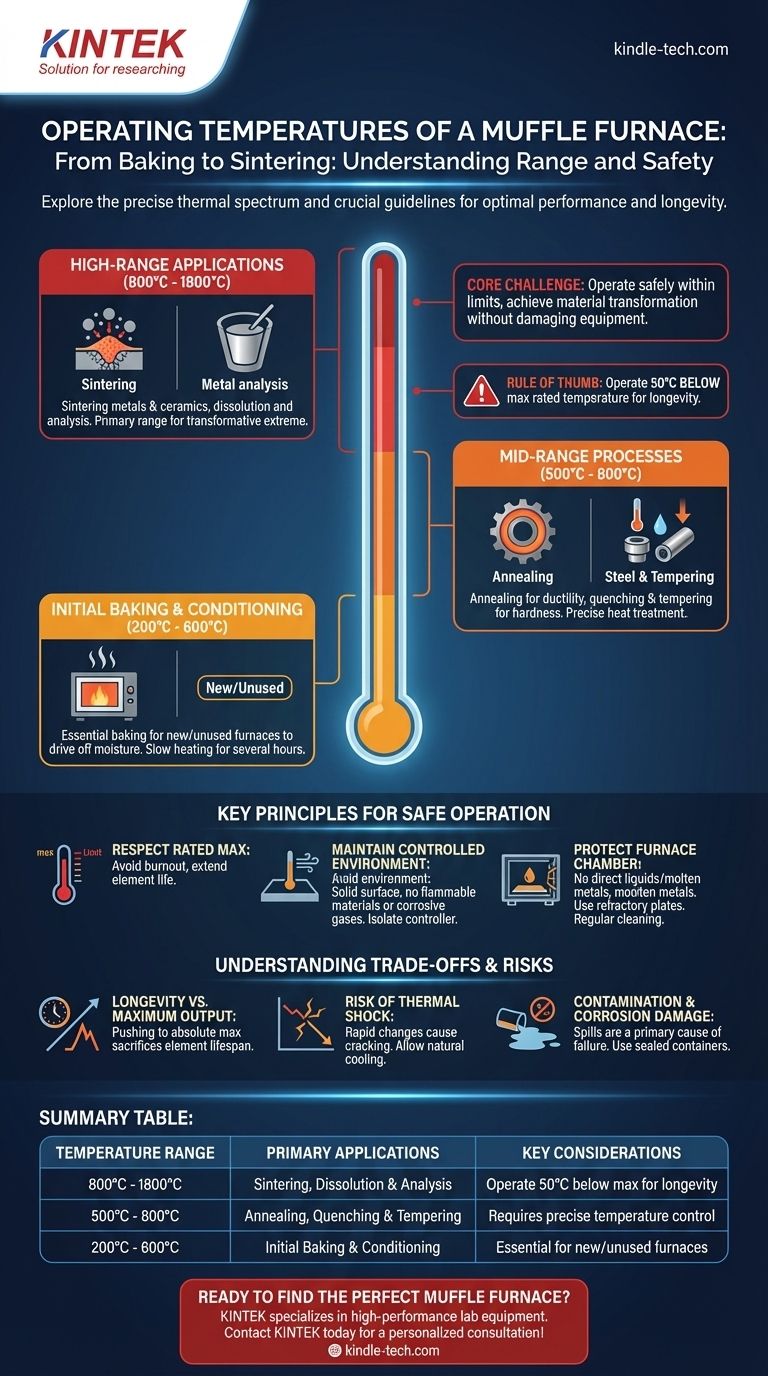

In short, a muffle furnace operates at high temperatures, typically ranging from 800°C to as high as 1800°C. The specific temperature depends entirely on the furnace's design and the intended application, such as sintering metals or annealing steel parts.

A muffle furnace is not defined by a single operating temperature, but by its rated temperature range. The core challenge is not just reaching a high temperature, but operating the furnace safely and effectively within its specific limits to achieve your desired material transformation without damaging the equipment.

The Temperature Spectrum and Its Applications

A muffle furnace's utility comes from its ability to achieve precise temperatures for different processes. These can be broken down into distinct operational ranges.

High-Range Applications (800°C - 1800°C)

This is the primary range for transformative processes that require extreme heat. It is commonly used in industrial and scientific settings for tasks like sintering, where powdered materials are fused together.

This range is also used for the dissolution and analysis of durable materials like metals and ceramics, which require high thermal energy to break down their structure.

Mid-Range Processes (500°C - 800°C)

The lower end of the high-temperature spectrum is critical for heat treatment processes. This includes annealing, which alters a material's microstructure to make it more ductile and workable.

It is also used for quenching and tempering small steel components, processes that carefully control heating and cooling to achieve specific hardness and durability characteristics.

Initial Baking and Conditioning (200°C - 600°C)

Before a new muffle furnace (or one that has been unused for a long time) is put into service, it must be baked. This conditioning process involves heating the furnace slowly to between 200°C and 600°C for several hours to safely drive off any moisture from the insulation.

Key Principles for Safe Operation

Achieving high temperatures safely requires strict adherence to operational protocols. The primary goal is to protect both the operator and the longevity of the furnace itself.

Respect the Rated Maximum Temperature

Never exceed the furnace's rated temperature. Doing so can burn out the electric heating elements, leading to expensive and time-consuming repairs.

For optimal equipment life, it is best practice to operate at least 50°C below the maximum rated temperature. This reduces stress on the heating elements and extends the furnace's lifespan significantly.

Maintain a Controlled Environment

A muffle furnace must be placed on a solid, stable surface like a concrete table, away from any flammable or explosive materials. The surrounding air must be free of corrosive gases or conductive dust.

The furnace's controller is sensitive to heat and vibration. It should be positioned away from the main furnace body to prevent its electronic components from overheating.

Protect the Furnace Chamber

The internal furnace chamber is highly susceptible to damage. Never pour liquids or easily melted metals directly onto the furnace floor, as this can cause corrosion and thermal shock.

When heating materials that can release corrosive substances (like alkaline materials), use a refractory plate to protect the chamber lining. Regularly clean the chamber to remove any oxides or debris.

Understanding the Trade-offs and Risks

Using a muffle furnace involves balancing performance with equipment longevity and safety. Understanding these trade-offs is crucial for effective use.

Longevity vs. Maximum Output

Pushing a furnace to its absolute maximum rated temperature provides the highest thermal output but comes at a significant cost to the lifespan of the heating elements. The "50°C below max" rule is a direct trade-off that prioritizes long-term reliability over short-term peak performance.

Risk of Thermal Shock

Rapid temperature changes can cause thermal shock, cracking the furnace's ceramic insulation or damaging the thermocouple used for temperature measurement. This is why you must avoid removing items suddenly at high temperatures and always allow the furnace to cool down naturally after use.

Contamination and Corrosion Damage

Spills are a primary cause of furnace failure. Any liquid or molten material that touches the hot chamber floor can cause immediate, irreversible corrosion. This is why strict protocols against direct filling and the use of sealed containers for volatile substances are non-negotiable.

How to Apply This to Your Project

Your operational strategy should be dictated by your specific goal and the capabilities of your equipment.

- If your primary focus is industrial sintering or melting: Select a furnace with a maximum rated temperature well above your target process temperature to ensure you can operate reliably without stressing the components.

- If your primary focus is laboratory heat treatment: A mid-range furnace may be sufficient, but prioritize one with precise temperature control and ramping features to properly execute annealing or tempering cycles.

- If you are a first-time user or setting up a new furnace: Your absolute first step is to perform the initial baking procedure and thoroughly review all safety guidelines for your specific model.

Ultimately, mastering a muffle furnace is about treating it as a precision instrument, not just a simple oven.

Summary Table:

| Temperature Range | Primary Applications | Key Considerations |

|---|---|---|

| 800°C - 1800°C | Sintering, Dissolution & Analysis | Operate 50°C below max for longevity |

| 500°C - 800°C | Annealing, Quenching & Tempering | Requires precise temperature control |

| 200°C - 600°C | Initial Baking & Conditioning | Essential for new/unused furnaces |

Ready to find the perfect muffle furnace for your temperature requirements?

KINTEK specializes in high-performance lab equipment, including muffle furnaces designed for precise temperature control and durability. Whether your application requires sintering up to 1800°C or precise annealing cycles, our experts can help you select the right model to ensure safety, efficiency, and long-term reliability for your laboratory.

Contact KINTEL today for a personalized consultation and let us help you achieve superior thermal processing results!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the applications of muffle furnace in pharmaceutical industry? Ensure Drug Purity and Quality

- What precautions you will take while handling the muffle furnace? Ensure Safe and Efficient Operation

- Which gas is used in a muffle furnace? Choosing the Right Atmosphere for Your Lab Process

- What is an example of quenching? Achieve Optimal Hardness with Precise Cooling

- What energy transfer happens in a furnace? Master Convection, Conduction & Radiation for Your Process