For accurate X-Ray Fluorescence (XRF) analysis, the ideal particle size for your powdered sample should be below 50 micrometers (µm). This fine, flour-like consistency is critical for creating a homogeneous sample, which minimizes analytical errors and ensures the results are truly representative of the bulk material.

The ultimate goal of sample preparation is not just to reduce particle size, but to eliminate analytical errors caused by sample heterogeneity. A smaller, uniform particle size ensures that the X-ray beam interacts with a sample that is chemically and physically consistent, leading to precise and repeatable measurements.

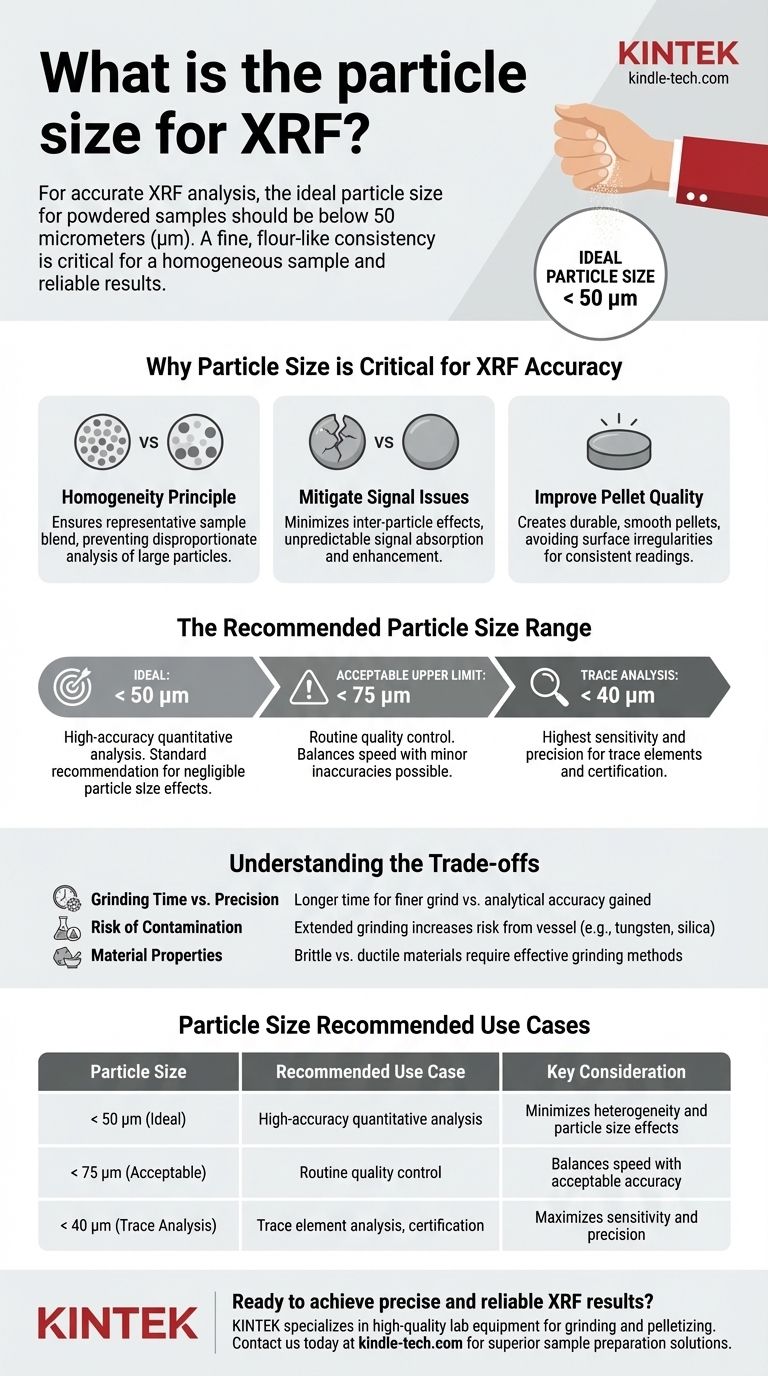

Why Particle Size is Critical for XRF Accuracy

The reliability of your XRF data is directly tied to the quality of your sample preparation. Inconsistent or large particle sizes introduce significant uncertainty, a phenomenon known as the "particle size effect."

The Principle of Homogeneity

XRF analyzes a relatively small surface area of your sample. If the sample contains large, distinct particles of different minerals or phases, the X-ray beam may disproportionately strike one type of particle.

This leads to a result that reflects that single particle, not the average composition of the entire sample. Grinding the material into a fine, uniform powder ensures that every portion of the sample is a representative blend of the whole.

Mitigating Signal Absorption and Enhancement

Large particles create microscopic voids and uneven surfaces within a pressed pellet. These irregularities can cause the emitted fluorescent X-rays from one element to be erratically absorbed or enhanced by neighboring particles.

This effect is unpredictable and element-dependent, leading to inaccurate quantification. A fine powder (sub-50 µm) packs tightly, minimizing these inter-particle effects and creating a dense, uniform medium for analysis.

Improving Pressed Pellet Quality

When preparing samples by pressing them into pellets, a fine particle size is essential for mechanical stability. Smaller particles have a greater surface area-to-volume ratio, which allows them to bind together more effectively under pressure.

This creates a durable pellet with a smooth, flat analytical surface. A rough or cracked surface can scatter the primary X-ray beam and lead to inconsistent, unreliable readings.

The Recommended Particle Size Range

While a single number is often cited, the acceptable range depends on your analytical goals.

The Ideal Target: Below 50 µm

For most quantitative applications requiring high accuracy, grinding your sample to a particle size of less than 50 µm is the standard recommendation. Some protocols suggest going even finer, to 40 µm or below.

This ensures that particle size effects are negligible for the majority of elements being analyzed. The target consistency should be similar to that of dry flour.

The Acceptable Upper Limit: Up to 75 µm

In some contexts, particularly for routine quality control where high precision is less critical than speed, a particle size of up to 75 µm can be acceptable.

However, be aware that at this size, particle size effects may begin to introduce minor inaccuracies, especially for lighter elements.

Understanding the Trade-offs

Achieving the ideal particle size involves balancing analytical requirements with practical limitations.

Grinding Time vs. Desired Precision

Reducing a sample to a sub-50 µm powder requires significant energy and time. You must decide if the analytical accuracy gained from finer grinding justifies the increased preparation time for your specific application.

Risk of Contamination

Extended grinding increases the risk of contamination from the grinding vessel itself (e.g., tungsten from a carbide mill or silica from an agate mortar). This is a critical consideration when performing trace element analysis, as the contamination could be higher than the element's concentration in the sample.

Material Properties

Not all materials grind equally. Brittle materials pulverize easily, while ductile or fibrous materials can be difficult to reduce in size. The chosen grinding method must be effective for your specific sample matrix.

Making the Right Choice for Your Goal

Select your target particle size based on the required data quality for your project.

- If your primary focus is routine process control: A particle size of less than 75 µm is often a sufficient and practical goal for achieving consistent results.

- If your primary focus is high-accuracy quantitative analysis: Aim for a particle size of less than 50 µm to minimize heterogeneity errors and ensure data reliability.

- If your primary focus is trace element analysis or certification: Grinding to the finest practical size, often below 40 µm, is necessary to achieve the highest sensitivity and precision.

Ultimately, consistent and methodical sample preparation is the foundation upon which all accurate XRF analysis is built.

Summary Table:

| Particle Size Range | Recommended Use Case | Key Consideration |

|---|---|---|

| < 50 µm (Ideal) | High-accuracy quantitative analysis | Minimizes heterogeneity and particle size effects |

| < 75 µm (Acceptable) | Routine quality control | Balances speed with acceptable accuracy |

| < 40 µm (Trace Analysis) | Trace element analysis, certification | Maximizes sensitivity and precision |

Ready to achieve precise and reliable XRF results in your lab?

Proper sample preparation is the foundation of accurate analysis. KINTEK specializes in high-quality lab equipment and consumables for grinding and pelletizing, ensuring your powdered samples meet the ideal particle size specifications for XRF.

Our solutions help you:

- Minimize analytical errors with consistent, homogeneous samples.

- Improve data reliability for both routine and high-precision applications.

- Streamline your workflow with robust and efficient grinding tools.

Contact us today to discuss your specific laboratory needs and let our experts help you select the right equipment for superior sample preparation. Get in touch via our contact form to get started!

Visual Guide

Related Products

- Three-dimensional electromagnetic sieving instrument

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- Laboratory Disc Cup Vibratory Mill for Sample Grinding

- Laboratory High Throughput Tissue Grinding Mill Grinder

- Laboratory Hybrid Tissue Grinding Mill

People Also Ask

- What is powder sieving? A Guide to Accurate Particle Size Separation

- What are the applications of sieving machine? From Mining to Pharmaceuticals

- What is the use of vibrating sieve machine? Achieve Precise Particle Size Analysis for Your Lab

- What is the operating procedure of a sieve shaker? Master Accurate Particle Size Analysis

- What are the different types of sieving machines? Choose the Right Motion for Your Material