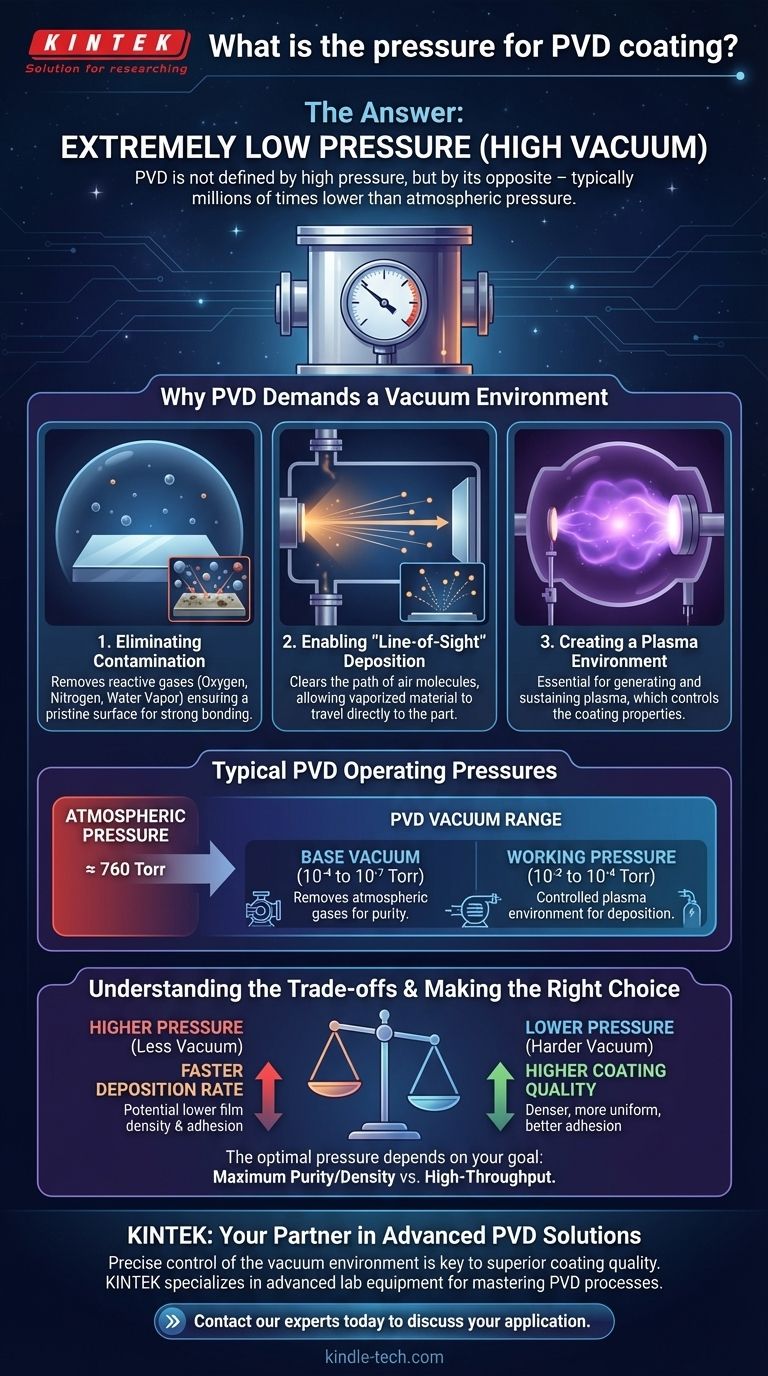

The short answer is counterintuitive: Physical Vapor Deposition (PVD) is not defined by high pressure, but by its opposite. The process is conducted in a high-vacuum environment, which is a state of extremely low pressure, typically millions of times lower than the air pressure we experience every day.

The critical factor for PVD coating is not the application of pressure, but the creation of a strong vacuum. This low-pressure environment is essential for ensuring the purity of the coating and allowing vaporized material to travel unimpeded from its source to the part's surface.

Why PVD Demands a Vacuum Environment

To understand the PVD process, you must first understand the fundamental role of the vacuum chamber. This controlled, low-pressure environment is not an incidental detail; it is the core requirement that makes the entire process possible.

Eliminating Contamination

Before coating, parts are meticulously cleaned to remove oils, oxides, and other contaminants. Exposing this clean surface to air would instantly create a new layer of oxidation and contamination.

The vacuum chamber is pumped down to remove reactive gases like oxygen, nitrogen, and water vapor. This ensures the pristine surface remains clean, allowing for a strong, direct bond between the substrate and the coating material.

Enabling "Line-of-Sight" Deposition

PVD works by vaporizing a solid material (the "target") into individual atoms or molecules. These vaporized particles must then travel through the chamber to land on the parts being coated.

In normal atmospheric pressure, these particles would collide with billions of air molecules, scattering them and preventing them from ever reaching the target. The vacuum clears this path, creating a "line-of-sight" trajectory for the coating material to deposit evenly onto the substrate.

Creating a Plasma Environment

Many modern PVD processes, such as sputtering, use a plasma (an ionized gas, typically argon) to bombard the coating source material.

This plasma can only be generated and sustained in a low-pressure environment. The vacuum allows for precise control over the introduction of this process gas, which is essential for controlling the final properties of the deposited film.

Typical PVD Operating Pressures

While "vacuum" is a general term, the specific level of pressure is a critical process parameter that is carefully controlled.

The High-Vacuum Range

The process begins by pumping the chamber down to a "base pressure," which is a very high vacuum, often in the range of 10⁻⁴ to 10⁻⁷ Torr (or roughly 10⁻² to 10⁻⁵ Pascals). This initial step removes the unwanted atmospheric gases.

The Role of Process Gas

Once the base pressure is achieved, a high-purity inert gas like Argon is often introduced into the chamber. This raises the pressure slightly to a "working pressure," typically around 10⁻² to 10⁻⁴ Torr.

This controlled, low-pressure gas environment is what is used to create the plasma for sputtering or to control the energy of the depositing particles. Even at this "higher" working pressure, the environment is still a very strong vacuum compared to atmosphere.

Understanding the Trade-offs

The precise working pressure is a variable that engineers adjust to change the characteristics of the final coating. It is not a single, fixed number.

Pressure vs. Deposition Rate

Generally, a higher working pressure (i.e., a less-intense vacuum) can lead to more collisions in the plasma, which can increase the rate at which the coating material is deposited. However, this often comes at a cost.

Pressure vs. Coating Quality

A lower working pressure (a harder vacuum) typically results in a higher-quality coating. The deposited film is often denser, more uniform, and has better adhesion because the coating particles arrive at the substrate with higher energy and fewer impurities.

Making the Right Choice for Your Goal

The optimal pressure depends entirely on the desired outcome for the coated part.

- If your primary focus is maximum purity and density: A lower working pressure (a higher vacuum) is the preferred choice to ensure a pristine environment and high-energy deposition.

- If your primary focus is high-throughput and speed: A slightly higher working pressure may be used to increase the deposition rate, accepting a potential trade-off in film density.

- If your primary focus is creating a specific film structure: The pressure will be carefully balanced with other variables, like temperature and bias voltage, to achieve the desired morphology.

Ultimately, controlling the low-pressure vacuum environment is the key to controlling the quality, durability, and performance of any PVD coating.

Summary Table:

| PVD Pressure Stage | Typical Pressure Range (Torr) | Purpose |

|---|---|---|

| Base Vacuum | 10⁻⁴ to 10⁻⁷ | Removes atmospheric gases and contaminants for a pure environment. |

| Working Pressure | 10⁻² to 10⁻⁴ | Creates a controlled plasma environment for the deposition process. |

Ready to achieve superior coating quality and performance?

The precise control of the vacuum environment is what makes PVD coatings so durable and effective. At KINTEK, we specialize in providing the advanced lab equipment and consumables needed to master processes like PVD coating. Whether you are developing new materials or optimizing production, our solutions are designed to meet the exacting demands of modern laboratories.

Let's discuss how we can support your specific application. Contact our experts today to find the right equipment for your PVD coating challenges.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is plasma enhanced chemical vapour deposition process? Unlock Low-Temperature, High-Quality Thin Films

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method