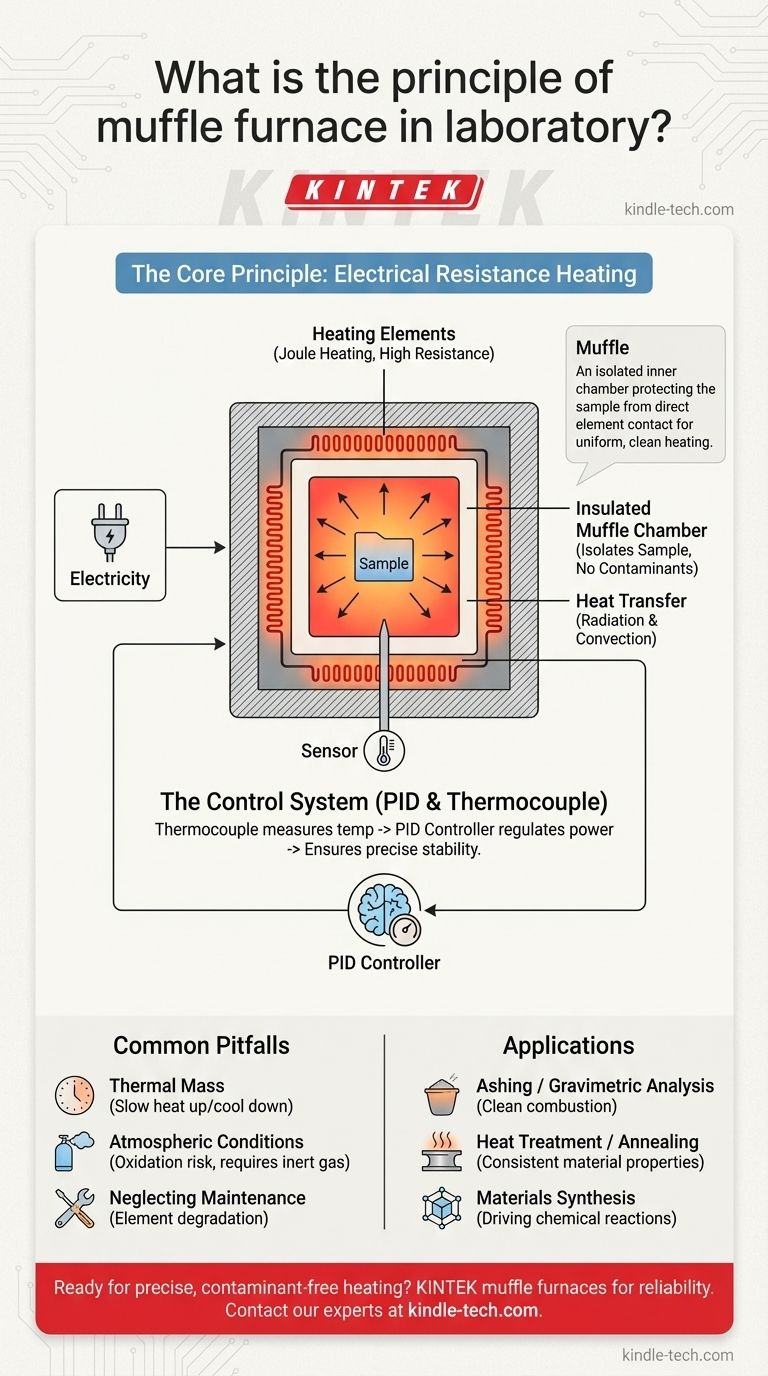

At its core, a laboratory muffle furnace operates on the principle of electrical resistance heating. It efficiently converts electrical energy into thermal energy within a highly insulated chamber, allowing it to reach and maintain very high temperatures in a controlled, clean environment. The key is isolating the sample from the heating elements to ensure uniform and contaminant-free heating.

The term "muffle" refers to the furnace's defining feature: an isolated inner chamber. This design ensures that the material being heated is protected from direct contact with the heating elements, allowing for extremely uniform heat transfer primarily through radiation and convection.

The Core Mechanism: From Electricity to Intense Heat

A muffle furnace's ability to generate high temperatures begins with a simple and powerful electrical principle. It is a system designed not just to get hot, but to do so with precision and efficiency.

The Principle of Resistance Heating

The furnace works by passing an electric current through specialized heating elements. These elements are made of materials with high electrical resistance, such as Nichrome or Kanthal alloys.

As electricity struggles to flow through this resistance, it generates intense heat. This phenomenon, known as Joule heating, is the fundamental energy conversion process at work.

The Role of the Insulated Chamber

The heating elements are wrapped around an inner chamber, often made of a high-purity ceramic material. This chamber is the muffle.

Its purpose is to hold the sample and to absorb and radiate the heat generated by the elements. It ensures there are no byproducts of combustion, providing a clean heating environment.

Heat Transfer via Radiation and Convection

Once the chamber walls are heated, they transfer this energy to the sample inside through two primary methods.

Thermal radiation is the dominant force, as the hot walls emit infrared energy that directly heats the sample. Thermal convection also plays a role, as the air inside the chamber heats up and circulates, further contributing to a uniform temperature.

The Brains of the Operation: The Control System

Achieving and holding a precise temperature is what makes a muffle furnace a critical scientific instrument. This is managed by an integrated electronic control system.

Measuring Temperature with a Thermocouple

A thermocouple, a sensor that measures temperature, is placed inside the chamber. It constantly sends real-time temperature data back to the furnace's controller.

Regulating Power with a Controller

The PID controller (Proportional-Integral-Derivative) acts as the furnace's brain. It compares the actual temperature from the thermocouple to the desired setpoint temperature.

Based on this difference, it intelligently pulses power to the heating elements, ensuring the temperature remains stable without overshooting or dropping significantly.

Common Pitfalls to Avoid

While robust, understanding the operational characteristics of a muffle furnace is key to achieving reliable and repeatable results.

Assuming Instantaneous Temperature Changes

The heavy insulation that makes the furnace so efficient also gives it significant thermal mass. It takes time to heat up to the setpoint and, just as importantly, a very long time to cool down safely. Always plan your experiments around these heating and cooling cycles.

Ignoring Atmospheric Conditions

A standard muffle furnace operates in ambient air. Heating certain materials in the presence of oxygen can lead to oxidation. If your process requires an inert atmosphere (like nitrogen or argon), you need a specially designed furnace with gas-purging capabilities.

Neglecting Proper Maintenance

The heating elements and thermocouple can degrade over time, especially with frequent high-temperature use. Regular inspection and periodic calibration are essential for ensuring the furnace operates accurately and safely.

How to Apply This to Your Project

Understanding these principles allows you to use the muffle furnace more effectively for your specific application.

- If your primary focus is ashing or gravimetric analysis: The key is the furnace's ability to provide a clean, high-temperature environment that completely combusts organic material without introducing contaminants.

- If your primary focus is heat treatment or annealing: The value lies in the precise, uniform heating provided by the PID controller and insulated chamber, which ensures consistent material properties.

- If your primary focus is materials synthesis: The furnace provides the stable, high-energy environment needed to drive chemical reactions and form new crystalline structures.

By understanding how a muffle furnace masterfully controls the conversion of electricity into heat, you can leverage it as a powerful and precise tool for your work.

Summary Table:

| Key Component | Function |

|---|---|

| Heating Elements | Convert electrical energy to heat via resistance (Joule heating). |

| Insulated Muffle Chamber | Isolates the sample for clean, uniform heating via radiation/convection. |

| PID Controller & Thermocouple | Precisely measures and regulates temperature for stability. |

Ready to achieve precise, contaminant-free heating in your lab?

KINTEK's muffle furnaces are engineered for reliability and accuracy in applications like ashing, heat treatment, and materials synthesis. Our expertise in lab equipment ensures you get a solution tailored to your specific thermal processing needs.

Contact our experts today to find the perfect muffle furnace for your laboratory!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How are high-temperature sintering furnaces and STA used for 3D-printed elastomers? Optimize Quality Control & Curing

- What role does a high-temperature muffle furnace play in the strain engineering of functional materials? Precise Control

- What is an oven furnace? Achieve Precise, Uniform Heat for Industrial & Lab Applications

- What role does a high-temperature muffle furnace play in BZCY72 densification? Master Precision Sintering at 1500°C

- What are sintered products typical uses? Creating Strong, Complex, and Specialized Components

- What are the limitations of using conventional sintering furnaces for SDC-carbonate green bodies? Solve Low Density

- Which type of material is used for overheating protection in muffle furnace? A Dual-Layer Safety System Explained

- What role does a high-temperature furnace play in the preparation of ceramic-enamel glass? Achieve Permanent Fusion