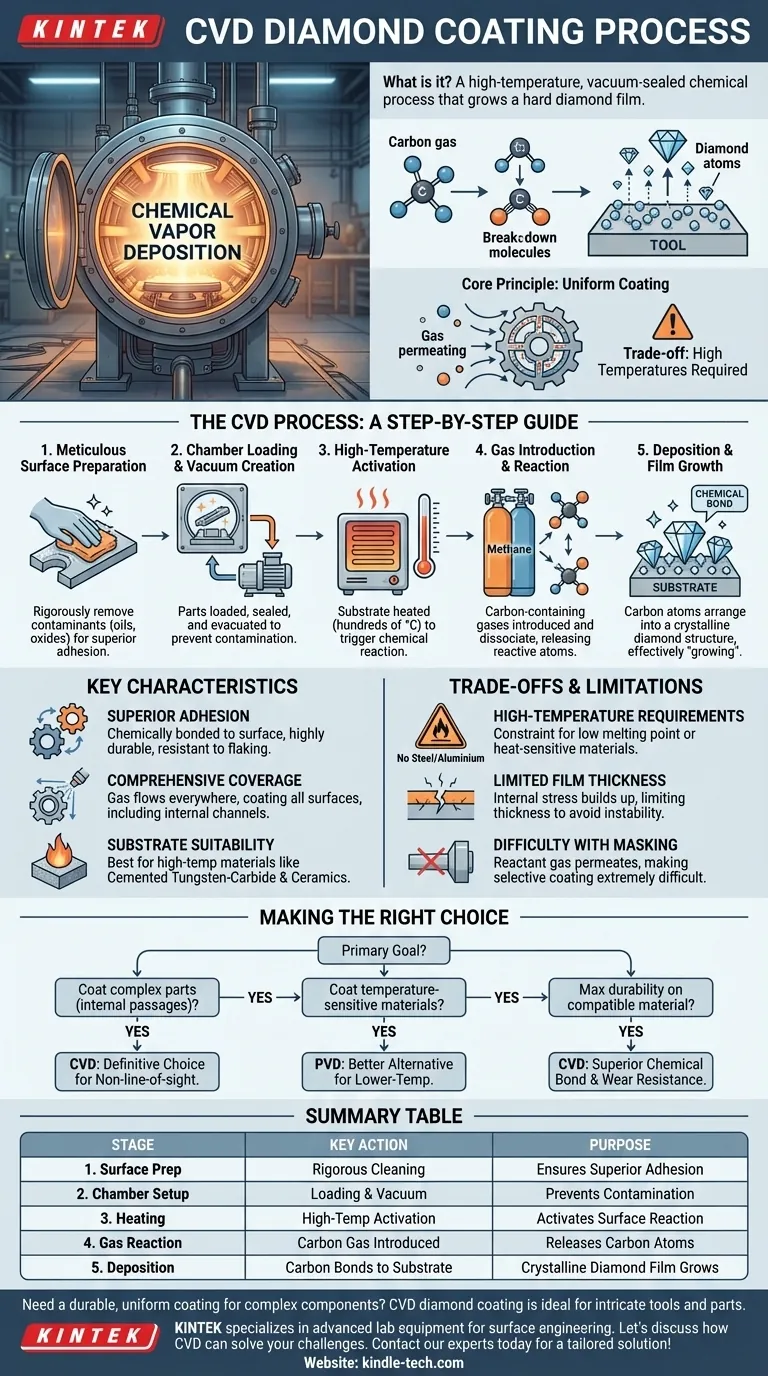

In essence, the Chemical Vapor Deposition (CVD) diamond coating process uses a high-temperature, vacuum-sealed environment to facilitate a chemical reaction. A carbon-containing gas is introduced, which breaks down and "grows" a thin, exceptionally hard film of diamond directly onto the surface of a component, creating a strong chemical bond.

The core principle of CVD diamond coating is its ability to uniformly coat every surface a gas can touch, including complex internal geometries. This advantage, however, comes with significant trade-offs: the process requires extremely high temperatures, limiting the types of materials that can be coated.

The CVD Diamond Coating Process: A Step-by-Step Guide

The CVD process is a carefully controlled chemical reaction designed to create a fully bonded, high-performance diamond layer. Each step is critical to achieving the desired adhesion and uniformity.

Step 1: Meticulous Surface Preparation

Before any coating can begin, the substrate (the part being coated) must be perfectly clean.

Any contaminants like oils, greases, or oxides are rigorously removed from the surface. This step is non-negotiable, as it ensures the chemical reaction can occur correctly and the diamond film can achieve superior adhesion.

Step 2: Chamber Loading and Vacuum Creation

The cleaned parts are loaded into a specialized CVD reactor chamber.

The chamber is then sealed and evacuated to create a high-vacuum environment. Removing other atmospheric gases prevents unwanted chemical reactions and contamination during the deposition phase.

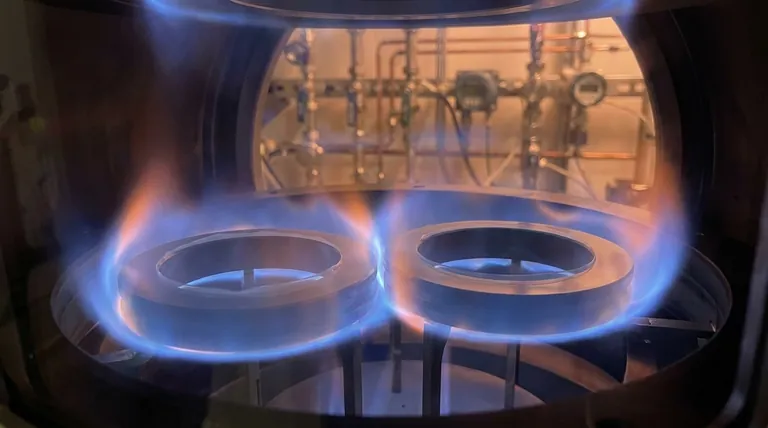

Step 3: High-Temperature Activation

The substrate is heated to an elevated temperature, often several hundred degrees Celsius.

This intense heat provides the necessary energy to trigger the chemical reaction on the part's surface. It is this high-temperature requirement that defines which materials are suitable for the CVD process.

Step 4: Gas Introduction and Reaction

A carefully controlled mixture of reactant gases, including a carbon source like methane, is introduced into the chamber.

The high temperature of the substrate causes these gas molecules to break down, or "dissociate," releasing reactive carbon atoms.

Step 5: Deposition and Film Growth

The free carbon atoms deposit onto the hot substrate and arrange themselves into a crystalline diamond structure.

This is not a simple layering but a chemical bond forming between the substrate and the new diamond film. The film effectively "grows" on the surface, atom by atom.

Key Characteristics of the CVD Method

Understanding the inherent characteristics of the CVD process is key to knowing when to apply it. It offers unique advantages that other methods, like Physical Vapor Deposition (PVD), cannot.

Superior Adhesion

Because the coating is chemically bonded to the surface during the reaction, the adhesion is exceptionally strong. This bond is integral to the substrate itself, making the coating highly durable and resistant to flaking or peeling under stress.

Comprehensive Coverage

Unlike line-of-sight processes like PVD, the reactant gases in a CVD chamber flow around the entire part. This allows the coating to be uniformly applied to all surfaces, including internal channels, threads, and blind holes.

Substrate Suitability

The CVD diamond process is best suited for materials that can withstand high temperatures without degrading. Cemented tungsten-carbide and certain ceramics are ideal candidates. For optimal adhesion on tungsten-carbide, a C-2 grade with 6% cobalt binder and a grain size above one micron is often required.

Understanding the Trade-offs and Limitations

No process is perfect. The strengths of CVD come with clear limitations that must be considered for any potential application.

High-Temperature Requirements

This is the most significant constraint. Materials with low melting points or those that would be structurally altered by intense heat (like many steels or aluminum alloys) cannot be coated using standard CVD methods.

Limited Film Thickness

As the diamond film grows, internal stresses build up within the coating. If the coating becomes too thick, this stress can cause it to become unstable or crack, limiting the maximum practical film thickness.

Difficulty with Masking

Because the reactant gas permeates the entire chamber, it is very difficult to selectively coat only specific areas of a part. The process naturally wants to coat everything it can reach.

Making the Right Choice for Your Application

Choosing a coating technology requires aligning the process capabilities with your primary engineering goal.

- If your primary focus is coating complex parts with internal passages or threads: CVD is the definitive choice due to its non-line-of-sight application.

- If your primary focus is coating temperature-sensitive materials: You must use a lower-temperature process, making PVD a more suitable alternative.

- If your primary focus is achieving maximum durability on a compatible material (like carbide tooling): CVD's superior chemical bond provides exceptional adhesion and wear resistance.

Ultimately, understanding these fundamental principles empowers you to select the right tool for the job.

Summary Table:

| Process Stage | Key Action | Purpose |

|---|---|---|

| 1. Surface Prep | Rigorous cleaning of the substrate | Ensures superior adhesion by removing contaminants |

| 2. Chamber Setup | Loading parts and creating a vacuum | Prevents unwanted reactions and contamination |

| 3. Heating | Raising substrate to high temperature | Activates the chemical reaction on the surface |

| 4. Gas Reaction | Introducing carbon-source gas (e.g., methane) | Gas molecules break down, releasing carbon atoms |

| 5. Deposition | Carbon atoms bond to the substrate | A crystalline diamond film 'grows' atom by atom |

Need a durable, uniform coating for complex components?

The CVD diamond coating process is ideal for parts with intricate geometries, like tools, inserts, and components with internal channels, where superior adhesion and comprehensive coverage are critical. KINTEK specializes in advanced lab equipment and consumables for surface engineering applications, helping laboratories achieve peak performance and durability.

Let's discuss how CVD coating can solve your wear resistance challenges. Contact our experts today for a tailored solution!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond for Thermal Management Applications

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- CVD Diamond Domes for Industrial and Scientific Applications

People Also Ask

- What is the advantage of chemical Vapour deposition CVD over oxidation? Versatile Thin Film Deposition

- What is the role of argon in sputtering? The Key to Efficient, High-Purity Thin Film Deposition

- What is the primary condition that defines the type of reaction in CVD? Master Substrate Temperature Control

- What is MOCVD used for? Precision Manufacturing for LEDs, Lasers, and RF Semiconductors

- What is the function of a CVD system in tungsten neutron target manufacturing? Ensure Durability with Tantalum Coating

- What is thin film deposition by magnetron sputtering? A Guide to High-Precision Coating

- What is coating in thin film? A Guide to Surface Engineering for Superior Material Performance

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer