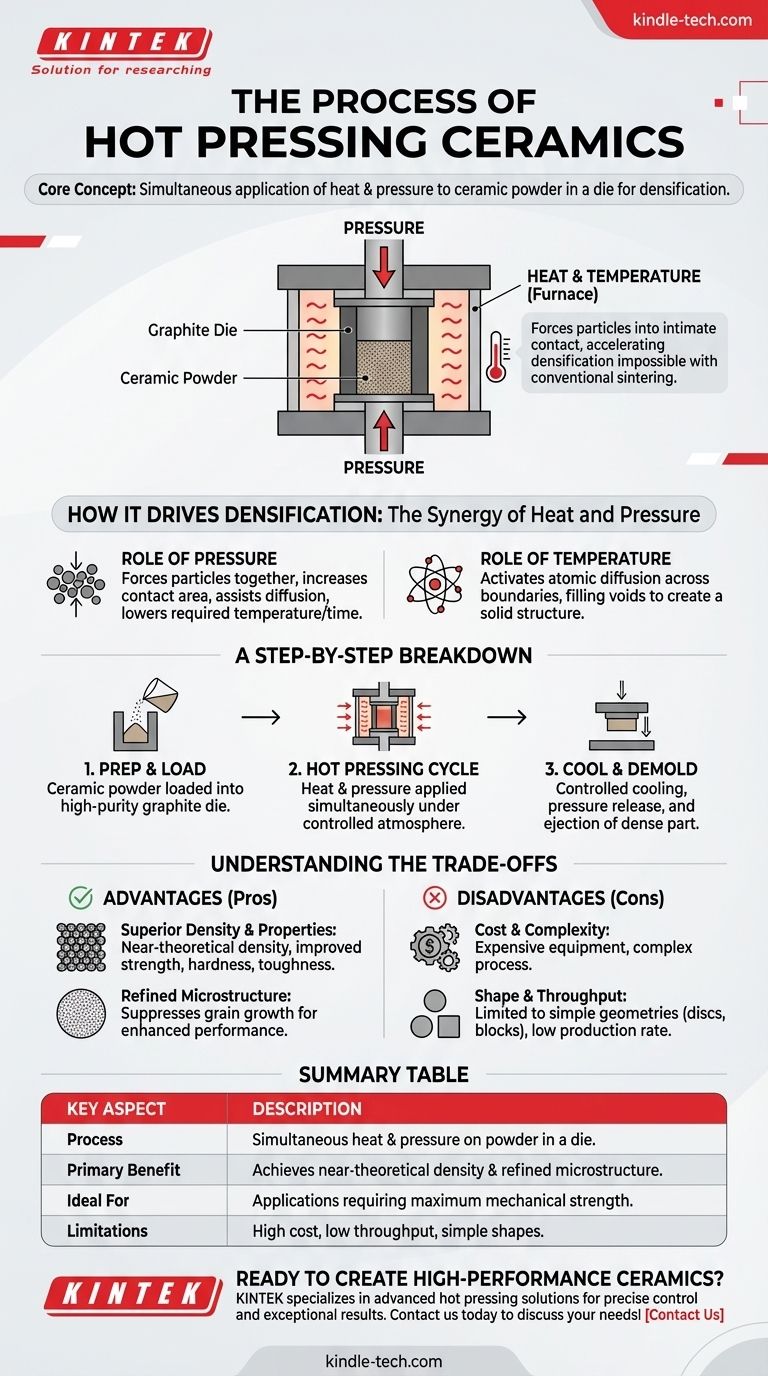

At its core, hot pressing is a materials processing technique where ceramic powder is simultaneously compacted by high pressure and sintered at high temperatures within a single process. This is accomplished by loading the powder into a die, typically made of graphite, and then applying both heat from a furnace and mechanical force via a plunger to achieve a highly dense, solid component.

By applying external pressure during the heating cycle, hot pressing forces powder particles into intimate contact, accelerating densification and allowing for the creation of superior ceramic materials that are often impossible to achieve through conventional, pressureless sintering.

How Hot Pressing Drives Densification

The Synergy of Heat and Pressure

The defining feature of hot pressing is the simultaneous application of heat and pressure. Unlike conventional sintering which relies solely on heat, this dual-action approach fundamentally changes how the material consolidates.

The Role of Pressure

External pressure forces the individual ceramic powder particles together. This action breaks down particle agglomerates and dramatically increases the particle-to-particle contact area, which is essential for the diffusion and material transport that lead to densification. This pressure-assisted mechanism allows densification to occur at significantly lower temperatures and in less time.

The Role of Temperature

Heat provides the necessary thermal energy to activate atomic diffusion. At elevated temperatures, atoms move across the boundaries of the contacting powder particles, filling the voids between them and creating a solid, dense structure.

The Hot Pressing Process: A Step-by-Step Breakdown

Step 1: Material Preparation and Mold Loading

The process begins with a carefully selected ceramic powder. The powder is loaded into a die, which is most often made of high-purity graphite due to its strength at high temperatures and chemical stability.

Step 2: The Hot Pressing Cycle

The loaded die is placed inside a specialized furnace. The cycle begins by heating the die and powder according to a precise temperature profile, often in a vacuum or inert gas atmosphere to prevent oxidation.

Simultaneously, or at a specific temperature, pressure is applied to the powder via one or more plungers. This pressure is maintained throughout the high-temperature phase of the cycle.

Step 3: Controlled Cooling and Demolding

After the desired time at peak temperature and pressure (known as the "soak" time), the component is cooled. The cooling rate is carefully controlled to prevent thermal shock and cracking. Once cooled, the pressure is released, and the newly formed, dense ceramic part is ejected from the die.

Understanding the Trade-offs

Advantage: Superior Density and Properties

The primary benefit of hot pressing is its ability to produce ceramics with near-theoretical density. This lack of porosity results in significantly improved mechanical properties, such as higher strength, hardness, and fracture toughness.

Advantage: Refined Microstructure

Because densification can be achieved at lower temperatures and for shorter times, hot pressing can suppress excessive grain growth. A finer grain structure is a key contributor to enhanced mechanical performance in most ceramics.

Disadvantage: Cost and Complexity

Hot pressing equipment is expensive and requires sophisticated control systems for temperature, pressure, and atmosphere. The overall process is more complex and costly per part compared to conventional sintering.

Disadvantage: Shape Limitation and Throughput

The process is typically limited to producing parts with simple geometries, such as discs, blocks, or cylinders, due to the uniaxial nature of the pressure application. As a batch process, it has a very low production throughput and is not suitable for mass production.

Making the Right Choice for Your Application

Selecting the right manufacturing process depends entirely on your end goal.

- If your primary focus is achieving maximum material performance: Hot pressing is the ideal choice for creating dense, fine-grained ceramics with exceptional mechanical and optical properties.

- If your primary focus is cost-effective mass production: You should explore alternative methods like conventional sintering or powder injection molding, as hot pressing has high costs and low throughput.

- If your primary focus is producing geometrically complex parts: Consider techniques like additive manufacturing (3D printing) or slip casting, as hot pressing is best suited for simple shapes.

Ultimately, understanding these core principles empowers you to leverage hot pressing to achieve specific, high-performance material outcomes.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Simultaneous application of heat and pressure to ceramic powder in a die. |

| Primary Benefit | Achieves near-theoretical density and refined microstructure. |

| Ideal For | Applications requiring maximum mechanical strength and performance. |

| Limitations | High cost, low throughput, and limited to simple shapes like discs or cylinders. |

Ready to create high-performance ceramics with superior density and mechanical properties?

KINTEK specializes in advanced lab equipment, including hot pressing solutions, to help you achieve precise temperature control, uniform pressure application, and exceptional material outcomes. Whether you're developing advanced components or optimizing material performance, our expertise ensures you get the reliable, high-quality results your laboratory demands.

Contact us today to discuss how our hot pressing equipment can meet your specific ceramic processing needs!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What is the significance of precise temperature control in melt infiltration? Achieve High-Performance Li-Alloy Electrodes

- Why is precise temperature control necessary for SiC/Cu Vacuum Hot Pressing? Mastering the Cu9Si Interface Phase

- What are the advantages of using a vacuum hot press for CuCr50? Achieve Superior Density & Purity in Alloy Production

- What role does a high-temperature hot press play in the sintering of NITE-SiC? Optimize Your Densification Process