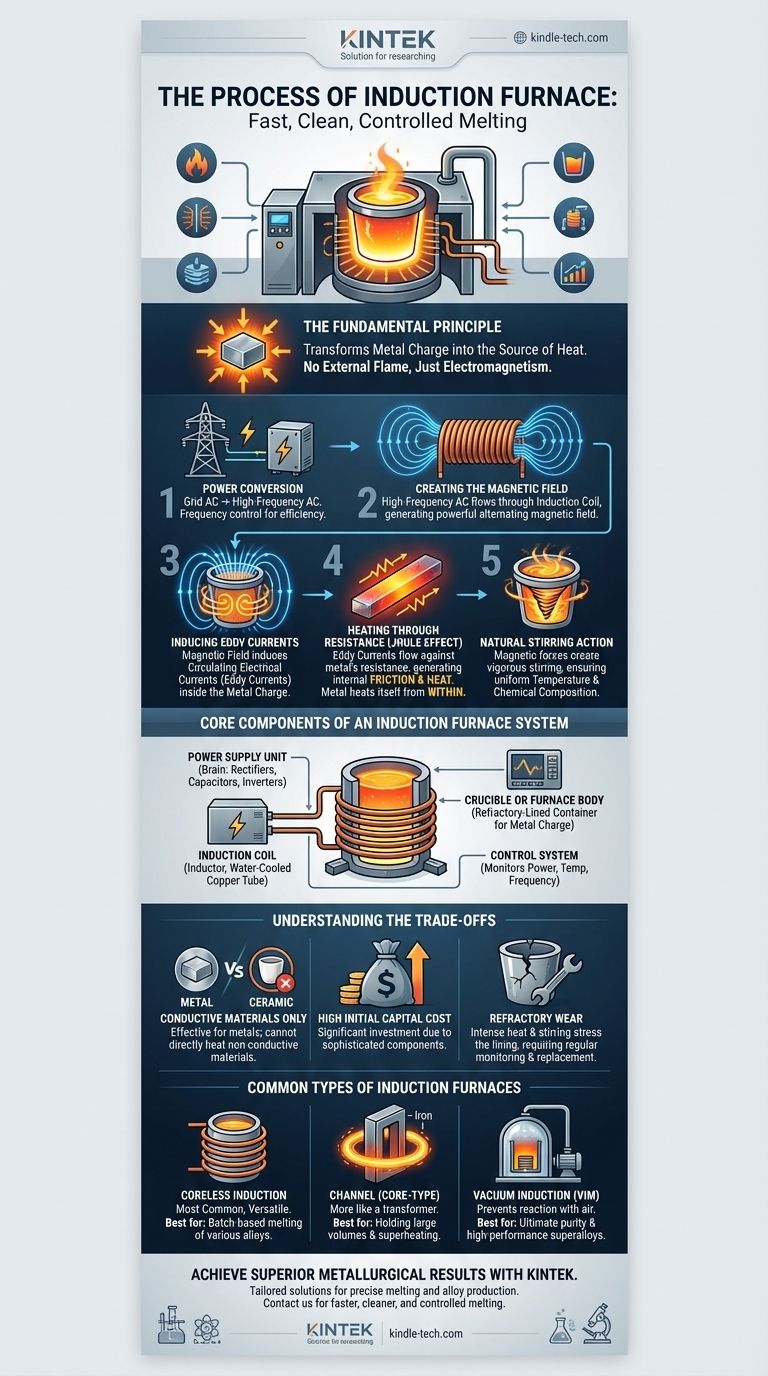

At its core, the induction furnace process uses a powerful, alternating magnetic field to induce electrical currents directly within the metal to be melted. These currents, known as eddy currents, generate intense heat through the metal's own electrical resistance, causing it to melt rapidly and efficiently without any external flame or heating element making direct contact.

The fundamental principle of an induction furnace is transforming the metal charge itself into the source of heat. By using electromagnetism, the furnace bypasses conventional heating methods, leading to faster, cleaner, and more controlled melting.

The Fundamental Principle: How Induction Generates Heat

To truly understand the process, it's best to think of it as a sequence of steps that transforms electrical energy into thermal energy inside the target material.

Step 1: Power Conversion

The process begins with the power supply. It takes standard three-phase alternating current (AC) from the electrical grid (e.g., 50/60 Hz).

This grid power is converted into a different form, often rectified into direct current (DC) and then inverted back into a single-phase AC at a much higher frequency (typically 150 Hz to 8,000 Hz). This frequency control is critical for efficiency.

Step 2: Creating the Magnetic Field

This high-frequency AC is sent through a hollow copper coil, known as an inductor.

As the current flows through the coil, it generates a powerful and rapidly alternating magnetic field in the space within and around the coil.

Step 3: Inducing Eddy Currents

The metal to be melted (the "charge") is placed inside a crucible, which sits within the induction coil. The powerful magnetic field passes directly through the conductive metal.

This fluctuating field induces circulating electrical currents within the metal charge itself. These are called eddy currents.

Step 4: Heating Through Resistance (Joule Effect)

The metal has natural electrical resistance. As the induced eddy currents flow against this resistance, they generate tremendous friction and heat. This phenomenon is known as the Joule effect.

Crucially, the heat is generated inside the metal. The furnace is not heating the metal; the metal is heating itself from within, leading to very rapid and uniform melting.

Step 5: Natural Stirring Action

The magnetic forces and the movement of the eddy currents create a vigorous stirring or circulating effect within the molten metal.

This inherent stirring action is a major advantage, as it ensures the melt has a uniform temperature and chemical composition, which is vital for producing high-quality alloys.

Core Components of an Induction Furnace System

An induction furnace is more than just a box; it's a system of carefully integrated components.

The Power Supply Unit

This is the brain of the furnace. It performs the critical task of converting grid power into the high-frequency current needed to drive the induction process. It includes rectifiers, capacitors, and inverters.

The Induction Coil (Inductor)

This is typically a tube of heavy-duty copper, wound into a coil. It is often hollow to allow for water cooling, as the massive currents it carries generate their own heat.

The Crucible or Furnace Body

This is the refractory-lined container that holds the metal charge. It must be ableto withstand extreme temperatures and is made of a material that does not react with the molten metal.

The Control System

This modern electronic system monitors and regulates the entire process. It controls power levels, frequency, temperature, and cooling systems to ensure safe and efficient operation.

Understanding the Trade-offs

While highly effective, the induction process has specific characteristics that present trade-offs.

Requirement for Conductive Materials

The entire principle relies on inducing current in the charge. Therefore, induction furnaces are only effective for melting electrically conductive materials, primarily metals. They cannot be used to directly heat non-conductive materials like ceramics.

High Initial Capital Cost

The sophisticated power electronics, heavy copper coils, and robust control systems make induction furnaces a significant capital investment compared to simpler combustion-based furnaces.

Refractory Wear

The intense heat and vigorous stirring action of the molten bath place significant stress on the refractory lining of the crucible. This lining is a consumable item that requires regular monitoring and replacement, contributing to operational costs.

Common Types of Induction Furnaces

Different designs are optimized for different applications.

Coreless Induction Furnaces

This is the most common design, where the crucible containing the charge is placed directly inside the induction coil. They are versatile, ideal for a wide range of metals and alloys, and perfect for batch-based melting.

Channel (Core-Type) Induction Furnaces

This design operates more like a transformer. The induction coil is wound around an iron core, and a loop of molten metal forms the secondary coil. Heat is generated in this loop and circulates into a larger bath. These are better suited for holding large volumes of molten metal at temperature rather than for melting from cold.

Vacuum Induction Furnaces (VIM)

A coreless furnace is housed inside a chamber from which all air is removed. Melting in a vacuum prevents the molten metal from reacting with oxygen and other gases, which is essential for producing high-purity, high-performance superalloys for aerospace or medical applications.

Making the Right Choice for Your Application

- If your primary focus is flexible, batch-based melting of various alloys: A coreless induction furnace offers the best versatility and control.

- If your primary focus is large-volume holding or superheating of a single metal: A channel induction furnace provides excellent energy efficiency for maintaining temperature.

- If your primary focus is ultimate purity and quality for reactive metals: A vacuum induction furnace is the only choice for eliminating gas contamination.

Understanding this process empowers you to select and operate the precise technology needed to achieve superior metallurgical results.

Summary Table:

| Key Stage | Process | Purpose |

|---|---|---|

| Power Conversion | Converts grid AC to high-frequency AC | Creates the right current for efficient heating |

| Magnetic Field Creation | High-frequency AC flows through a copper coil | Generates a powerful, alternating magnetic field |

| Eddy Current Induction | Magnetic field passes through conductive metal charge | Induces electrical currents (eddy currents) inside the metal |

| Joule Heating | Eddy currents flow against metal's electrical resistance | Generates intense internal heat to melt the metal |

| Natural Stirring | Magnetic forces create circulation in the molten metal | Ensures uniform temperature and chemical composition |

Ready to achieve superior metallurgical results?

At KINTEK, we specialize in providing high-performance lab equipment, including induction furnaces tailored for precise metal melting and alloy production. Whether you need the versatility of a coreless furnace, the efficiency of a channel furnace, or the ultimate purity of a vacuum induction furnace, our solutions deliver faster melting, cleaner results, and exceptional control.

Let our experts help you select the right technology for your laboratory's specific needs. Contact KINTEK today for a consultation and see how our reliable equipment can enhance your R&D and production processes.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- What is a tubular furnace used for? Precision Heating for Material Synthesis & Analysis

- How is temperature controlled in a furnace? Mastering Precise Thermal Management

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis