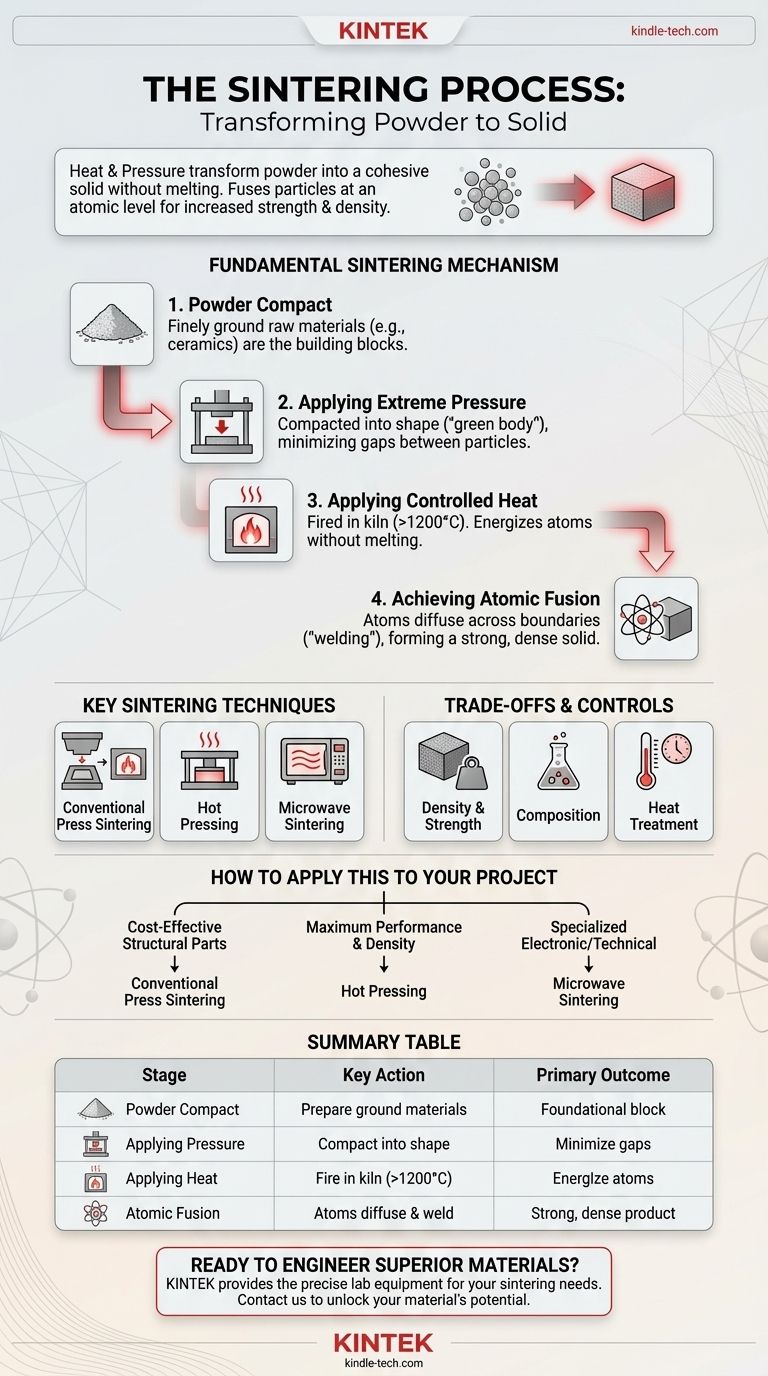

In essence, sintering is a manufacturing process that uses heat and pressure to transform a powder-like substance into a solid, cohesive mass. Crucially, this is achieved without melting the material; instead, the particles are fused together at an atomic level, dramatically increasing the material's strength and density.

Sintering is fundamentally about reducing the empty space between individual particles. By applying intense heat and pressure, you encourage atoms to diffuse across the boundaries of the particles, effectively welding them into a single, solid object with engineered properties.

The Fundamental Sintering Mechanism

Sintering is a multi-stage process that systematically eliminates the porosity of a compacted powder. Each step is critical to forming a dense and robust final product.

Starting with a Powder Compact

The process begins with finely ground raw materials. For sintered ceramics, this can include natural substances like clay, silica, feldspars, quartz, and mineral pigments. This powder is the foundational building block of the final object.

Applying Extreme Pressure

Next, the powder is compacted into a desired shape. This step, sometimes called "press molding," uses immense pressure to force the individual particles into close contact, minimizing the gaps between them. The pressure can be extreme, sometimes compared to the weight of the Eiffel Tower.

Applying Controlled Heat

The compacted material is then fired in a kiln at very high temperatures, often exceeding 1200°C. This thermal energy is the key to the process. It doesn't melt the material but instead energizes the atoms, causing them to move and diffuse across the boundaries where particles touch.

Achieving Atomic Fusion

As atoms migrate between particles, the boundaries between them disappear. This atomic diffusion effectively "welds" the particles together, creating a strong, dense, and solid slab from what was once a loose powder.

Key Sintering Techniques and Applications

While the core principle remains the same, different methods have been developed to sinter various materials, from common ceramics to high-performance electronic components.

Conventional Press Sintering

This is the most common method for many ceramics. The material is first compressed into a shape (the "green body") and then fired in a kiln. It is a reliable and widely used technique for a vast range of products.

Hot Pressing

For materials that are particularly difficult to densify, heat and pressure are applied simultaneously. This technique, known as hot pressing, is widely used for producing specialized, low-porosity materials like nano-ceramics where maximum density is critical.

Microwave Sintering

This is a more advanced technique that uses microwave radiation to heat the material internally and more uniformly. It is used to create high-quality, specialized materials such as PZT piezoelectric ceramics, silicon nitride, and other electronic ceramic devices where precise control over the final structure is necessary.

Understanding the Trade-offs and Controls

Sintering is not a one-size-fits-all process. The final characteristics of the sintered object are directly controlled by manipulating the process variables. This is where the engineering of the material truly happens.

The Impact of Density

The amount of pressure and the temperature profile directly influence the final density of the material. A higher density generally correlates with greater strength and durability, while controlled porosity can be engineered for applications like filters.

The Role of Composition

The final properties can be fundamentally altered by changing the initial powder composition. Introducing different alloys, binders, or mineral pigments before sintering allows for the creation of materials with a wide range of custom properties, from color to electrical conductivity.

The Effect of Heat Treatment

Just like with metals, the sintered part can undergo further heat treatments after the initial firing. These subsequent cycles can further refine the material's grain structure and mechanical properties, tailoring it for a specific application.

How to Apply This to Your Project

The chosen sintering method and parameters depend entirely on the desired outcome for the final material.

- If your primary focus is cost-effective production of structural parts: Conventional press sintering offers a robust and scalable process for materials like standard ceramics.

- If your primary focus is maximum performance and density: Hot pressing is the superior choice for advanced materials that resist densification under normal conditions.

- If your primary focus is creating specialized electronic or technical components: Advanced methods like microwave sintering provide the control needed to produce high-purity, high-performance materials.

Ultimately, sintering is a powerful and versatile tool for converting simple powders into highly engineered solid components.

Summary Table:

| Sintering Stage | Key Action | Primary Outcome |

|---|---|---|

| Powder Compact | Finely ground materials are prepared. | Creates the foundational building block. |

| Applying Pressure | Powder is compacted into a shape (green body). | Forces particles into close contact, minimizing gaps. |

| Applying Heat | Compacted material is fired in a kiln (>1200°C). | Energizes atoms to diffuse across particle boundaries. |

| Atomic Fusion | Atoms migrate, welding particles together. | Forms a strong, dense, and solid final product. |

Ready to engineer superior materials for your laboratory?

The sintering process is key to creating high-performance components, from structural ceramics to advanced electronic devices. KINTEK specializes in providing the precise lab equipment and consumables needed to perfect your sintering applications, whether you require conventional kilns, hot presses, or advanced microwave systems.

Let our experts help you select the right tools to achieve the density, strength, and properties your project demands. Contact KINTEL today to discuss your specific laboratory needs and unlock the full potential of your materials.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What is the primary function of a vacuum hot pressing sintering furnace? Expert Guide for Ti-22Al-25Nb Fabrication

- What are the advantages of vacuum sintering? Achieve Superior Purity, Strength, and Performance

- How does a vacuum environment system contribute to the hot pressing sintering of B4C-CeB6? Unlock Peak Ceramic Density

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What are the advantages of a vacuum hot pressing furnace? Achieve high-density NTC ceramics with superior stability.