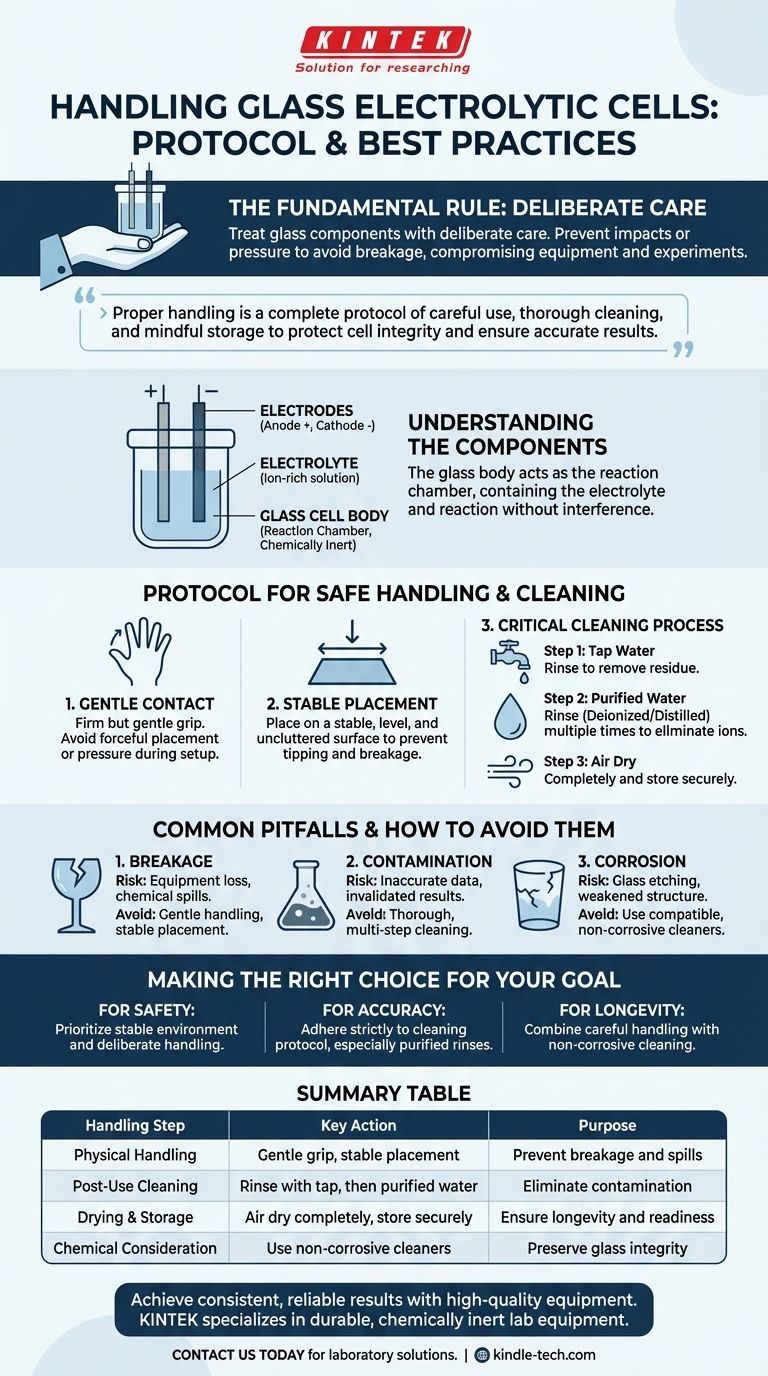

The fundamental rule for handling the glass components of an electrolytic cell is to treat them with deliberate care at all times. Because the glass body is fragile, it must be held gently and securely to prevent impacts or pressure that could lead to breakage, which compromises both the equipment and the experiment.

Proper handling is not just about avoiding physical damage; it is a complete protocol of careful use, thorough cleaning, and mindful storage designed to protect the integrity of the cell and ensure the accuracy of your results.

Understanding the Components and Their Purpose

An electrolytic cell is a system designed to use electrical energy to drive a non-spontaneous chemical reaction. Understanding its parts clarifies why the glass housing is so critical.

The Core Components

An electrolytic cell consists of two electrodes (a positive anode and a negative cathode) submerged in an electrolyte. This electrolyte is typically an ion-rich solution or a molten salt held within the cell's reaction chamber.

The Role of the Glass Cell Body

The glass component serves as the reaction chamber. Its primary function is to contain the electrolyte and the reaction itself. Glass is often used because it is chemically inert to many substances, preventing it from interfering with the electrochemical process.

A Protocol for Safe Handling and Cleaning

Proper handling extends through the entire lifecycle of an experiment, from setup to post-use cleaning.

Gentle Physical Contact

Always handle the cell body with a firm but gentle grip. Avoid setting it down forcefully on hard surfaces or applying pressure, especially when inserting or removing electrodes and other fittings.

Stable Placement

During assembly and operation, place the cell on a stable, level, and uncluttered surface. This minimizes the risk of accidental tipping or impact, which is a common cause of breakage.

The Critical Cleaning Process

After each use, residual electrolyte and reaction products must be completely removed to prevent contamination of future experiments.

- Initial Rinse: Begin by rinsing all glass parts thoroughly with tap water to remove the majority of the residue.

- Purified Water Rinse: Follow the tap water rinse with multiple rinses using deionized or distilled water. This step is crucial for removing any remaining ions that could skew future results.

- Drying and Storage: Allow the components to air dry completely or use a gentle stream of clean air. Store the clean, dry cell in a secure location where it will not be damaged.

Common Pitfalls and How to Avoid Them

Being aware of the risks associated with improper handling is key to maintaining a safe and effective lab environment.

The Obvious Risk: Breakage

The most immediate risk is breakage. This not only results in the loss of expensive equipment but can also lead to dangerous chemical spills of the electrolyte, posing a safety hazard.

The Subtle Risk: Contamination

Improper or incomplete cleaning is a more subtle but equally serious error. Leftover residue can contaminate subsequent experiments, leading to inaccurate and unreliable data. This invalidates the work performed.

The Chemical Risk: Corrosion

When using a cleaning agent for stubborn stains, you must ensure it is compatible with the glass. Aggressive cleaners can etch or damage the glass over time, weakening its structure and potentially interfering with future reactions.

Making the Right Choice for Your Goal

Your handling protocol should be guided by your primary objective.

- If your primary focus is safety: Prioritize a stable work environment and always handle the glass components deliberately and gently to prevent breakage and chemical spills.

- If your primary focus is experimental accuracy: Adhere strictly to the post-use cleaning protocol, especially the final rinses with deionized water, to eliminate any chance of cross-contamination.

- If your primary focus is equipment longevity: Combine careful physical handling with thorough, non-corrosive cleaning to preserve the structural integrity of the cell for long-term use.

Ultimately, treating the electrolytic cell with meticulous care is fundamental to achieving safe, repeatable, and accurate scientific outcomes.

Summary Table:

| Handling Step | Key Action | Purpose |

|---|---|---|

| Physical Handling | Gentle grip, stable placement | Prevent breakage and spills |

| Post-Use Cleaning | Rinse with tap water, then purified water | Eliminate contamination |

| Drying & Storage | Air dry completely, store securely | Ensure longevity and readiness |

| Chemical Consideration | Use non-corrosive cleaners | Preserve glass integrity |

Achieve consistent, reliable results with the right lab equipment. Proper handling is essential, but it starts with a high-quality electrolytic cell. KINTEK specializes in durable, chemically inert lab equipment and consumables designed for precision and safety. Contact us today to find the perfect solution for your laboratory's electrochemical needs and ensure the integrity of your experiments. Get in touch with our experts!

Visual Guide

Related Products

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- H Type Electrolytic Cell Triple Electrochemical Cell

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Electrolytic Electrochemical Cell for Coating Evaluation

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

People Also Ask

- What is a H type cell? A Guide to Divided Electrochemical Cells for Accurate Experiments

- What is the overall structure of the H-type double-layer optical water bath electrolytic cell? Precision Design for Controlled Experiments

- What optical features does the H-type electrolytic cell have? Precision Quartz Windows for Photoelectrochemistry

- What is the typical experimental system used with a double-layer water-bath electrolytic cell? Achieve Precise Electrochemical Control

- What is the purpose of the double-layer structure in the H-type electrolytic cell? Achieve Precise Thermal Control