In essence, a muffle furnace is a high-temperature oven that heats materials while isolating them from the heat source and any contaminants. Its primary purpose is to provide a clean, controlled environment for processes like ashing, heat-treating, or chemical analysis, ensuring the sample's integrity is not compromised by combustion byproducts like gas or ash.

The defining characteristic of a muffle furnace is not just its ability to reach high temperatures, but its fundamental design for heating without contamination. It achieves this by separating the material being heated from the actual source of the heat.

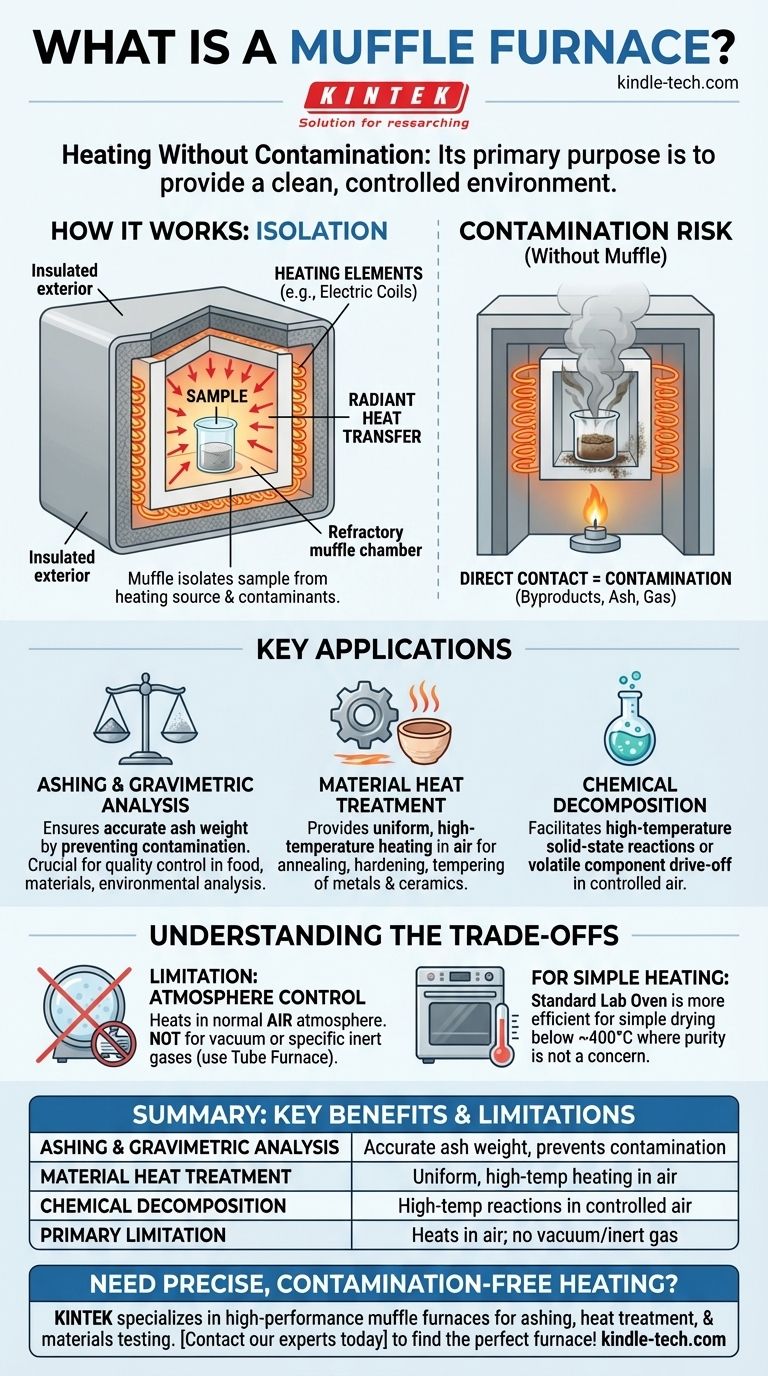

The Core Principle: Heating in Isolation

A muffle furnace operates on a simple but critical principle: the material being processed must not come into direct contact with the flames or electrical elements that generate the heat.

How Isolation Works

The term "muffle" refers to the furnace's inner chamber, which is typically made of high-temperature refractory materials. This chamber encloses the sample and separates it completely from the external heating elements.

Heat is transferred into the muffle chamber through convection and radiation, not direct contact. This design ensures that byproducts of combustion (in older fuel-fired models) or direct exposure to heating coils do not contaminate the sample.

The Modern Electric Design

While historically fueled by wood or coal, contemporary muffle furnaces are almost always electric. They use high-resistance heating coils that surround the exterior of the muffle chamber.

These coils generate intense heat, which radiates uniformly into the insulated chamber. This modern design is energy-efficient, provides precise temperature control, and completely eliminates the risk of contamination from fuel sources.

Key Applications in Research and Industry

The ability to heat a sample cleanly makes the muffle furnace an indispensable tool in many scientific and industrial fields.

Ashing and Gravimetric Analysis

One of the most common applications is ashing, which involves burning off organic substances to determine the non-combustible (ash) content. This is crucial for quality control in food science, materials testing, and environmental analysis.

The furnace's clean environment ensures that the final weight of the ash is accurate and not skewed by external residues.

Material Heat Treatment

Industries use muffle furnaces for various heat treatment processes on metals and ceramics. These can include annealing, hardening, and tempering, which alter the material's physical and chemical properties.

The uniform, high-temperature environment allows for predictable and repeatable results without introducing surface impurities.

Chemical Decomposition

In chemistry labs, muffle furnaces are used to drive off volatile components from a sample, decompose compounds, or facilitate high-temperature solid-state reactions. The isolated chamber guarantees that the reaction occurs in a controlled air atmosphere without unintended side reactions from contaminants.

Understanding the Trade-offs

While powerful, the muffle furnace is not the universal solution for all high-temperature needs. Understanding its primary limitation is key to using it correctly.

Atmosphere Control Limitations

A standard muffle furnace heats samples in a normal air atmosphere. It is designed to prevent contamination from the heat source, not to control the gaseous environment around the sample.

If a process requires heating in a vacuum or a specific inert gas (like argon or nitrogen), a tube furnace is the appropriate choice. A tube furnace is specifically designed to have its atmosphere purged and replaced.

When Simpler Heating is Sufficient

For simple drying or heating applications below approximately 400°C where atmospheric purity is not a concern, a standard laboratory oven is often more cost-effective and energy-efficient. A muffle furnace is specialized for high-temperature, high-purity applications.

Making the Right Choice for Your Process

Selecting the right heating equipment depends entirely on the requirements of your analysis or process.

- If your primary focus is high-purity ashing or gravimetric analysis: The muffle furnace is the correct and essential tool for the job.

- If your primary focus is general heat treatment of materials in an air atmosphere: The muffle furnace is a reliable and effective workhorse.

- If your primary focus is a reaction that requires an inert gas or vacuum: You need a specialized tube furnace, not a muffle furnace.

Ultimately, a muffle furnace is the standard for when you need to apply intense heat without compromising the chemical purity of your sample.

Summary Table:

| Application | Key Benefit |

|---|---|

| Ashing & Gravimetric Analysis | Ensures accurate ash weight by preventing contamination. |

| Material Heat Treatment | Provides uniform, high-temperature heating in air. |

| Chemical Decomposition | Allows high-temperature reactions in a controlled air atmosphere. |

| Primary Limitation | Heats in air; not suitable for vacuum or inert gas environments. |

Need precise, contamination-free heating for your laboratory processes?

KINTEK specializes in high-performance muffle furnaces and other lab equipment designed for applications like ashing, heat treatment, and materials testing. Our solutions ensure the sample integrity and accurate results your research demands.

Contact our experts today to find the perfect furnace for your specific needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Does melting point ever change? Unlock the Secrets of Pressure and Purity

- What are the different types of ash analysis? Dry vs. Wet Ashing Methods Explained

- What is a muffle furnace used for? Achieve Precise High-Temperature Processing in Your Lab

- What are muffle furnaces used for? Achieve Precise, Contaminant-Free High-Temperature Processing

- What is the theory of calcination? Master Precise Thermal Decomposition for Your Materials