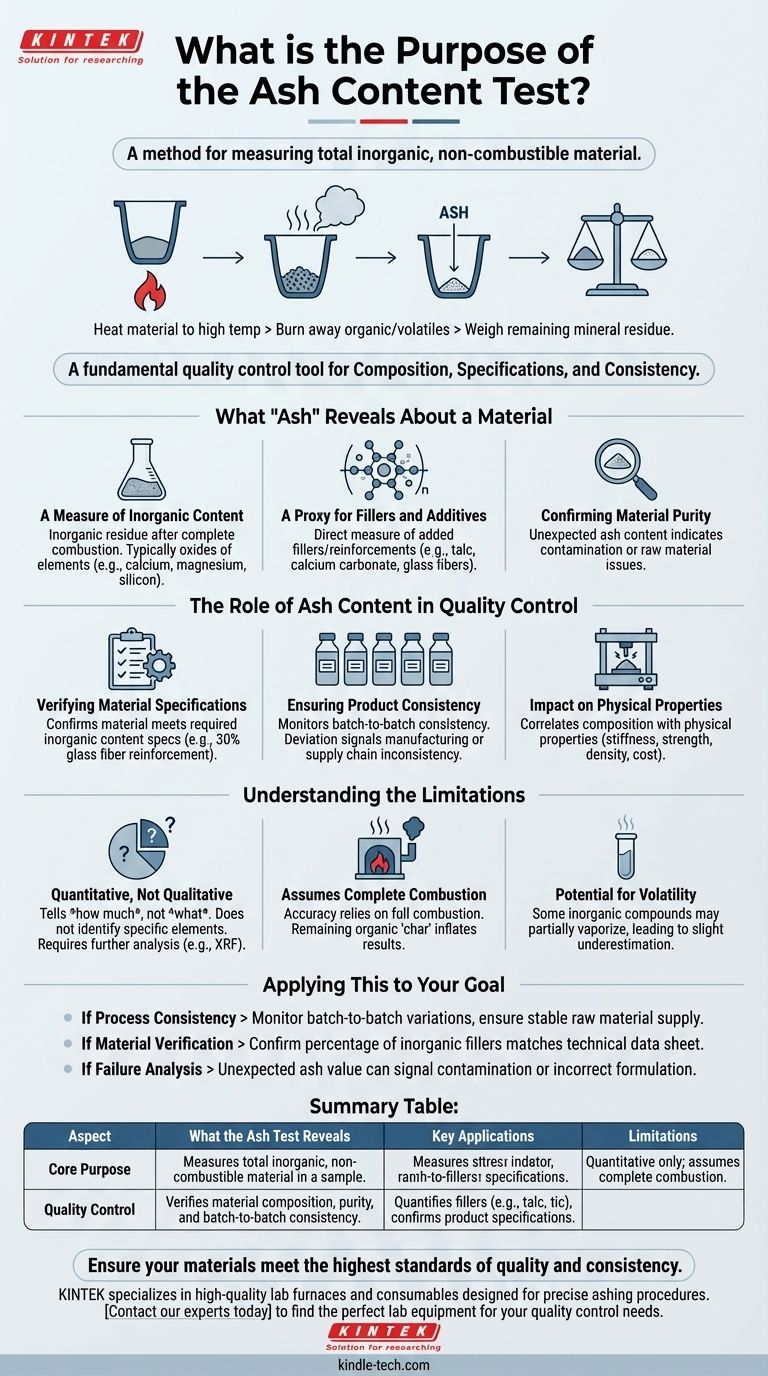

At its core, the ash content test is a method for measuring the total amount of inorganic, non-combustible material within a sample. The procedure involves heating a material to a high temperature until all the organic and volatile substances have been burned away, leaving only the mineral residue, or "ash," to be weighed.

The purpose of the ash test extends beyond simply measuring minerals. It is a fundamental quality control tool used to verify a material's composition, ensure it meets product specifications, and confirm its consistency.

What 'Ash' Reveals About a Material

The ash content test is a process of separation by fire. It cleanly divides a sample into its combustible and non-combustible components, offering a clear window into its fundamental makeup.

A Measure of Inorganic Content

The resulting ash is the inorganic residue left after complete combustion. This residue typically consists of the oxides of inorganic elements present in the original sample, such as calcium, magnesium, silicon, and others.

A Proxy for Fillers and Additives

In many industries, especially plastics and polymers, inorganic materials are deliberately added as fillers or reinforcements. The ash test provides a direct measure of the total quantity of these additives, such as talc, calcium carbonate, or glass fibers.

Confirming Material Purity

An unexpectedly high or low ash content can be an immediate indicator of contamination or an issue with the raw materials. It serves as a first-line diagnostic for material purity.

The Role of Ash Content in Quality Control

For a technical professional, the ash content value is not an abstract number. It is a critical data point for ensuring product quality and performance from the raw material stage to the finished product.

Verifying Material Specifications

Many materials have a required specification for inorganic content. For example, a polymer might be specified to contain 30% glass fiber reinforcement by weight. The ash test is the primary method used to confirm this specification has been met.

Ensuring Product Consistency

Monitoring the ash content of different production batches is a simple way to ensure consistency. A deviation in ash value from one batch to the next signals an inconsistency in the manufacturing process or raw material supply chain.

Impact on Physical Properties

The amount of inorganic filler dramatically affects a material's physical properties, including its stiffness, strength, density, and cost. The ash test helps correlate the material's composition with its expected performance characteristics.

Understanding the Limitations

While powerful, the ash test is a quantitative tool with specific limitations. Understanding these is crucial for accurate interpretation.

It's a Quantitative, Not Qualitative Test

The test tells you how much inorganic material is present, but it does not identify the specific elements or compounds. A 10% ash content could be calcium carbonate, talc, or a mix of various minerals. Further analysis, such as X-ray fluorescence (XRF), is required for that.

It Assumes Complete Combustion

The accuracy of the test relies on the complete combustion of all organic material. If any organic carbon "char" remains, it will be weighed as ash, leading to an artificially high and inaccurate result.

Potential for Volatility

Some inorganic compounds can partially vaporize or decompose at the high temperatures used in the test. This can lead to a slight underestimation of the total ash content, a factor that must be considered for high-precision applications.

Applying This to Your Goal

The utility of the ash test is defined by your objective. Use it as a targeted tool to answer specific questions about your material.

- If your primary focus is process consistency: Use the ash test to monitor batch-to-batch variations and ensure your raw material supply is stable.

- If your primary focus is material verification: Use the test to confirm that the percentage of inorganic fillers in a product matches its technical data sheet.

- If your primary focus is failure analysis: An unexpected ash value in a failed part can be a red flag for contamination or incorrect material formulation, guiding further investigation.

Ultimately, the ash content test provides a simple yet powerful metric for safeguarding material quality and performance.

Summary Table:

| Aspect | What the Ash Test Reveals |

|---|---|

| Core Purpose | Measures total inorganic, non-combustible material in a sample. |

| Quality Control | Verifies material composition, purity, and batch-to-batch consistency. |

| Key Applications | Quantifies fillers (e.g., talc, glass fiber), confirms product specifications. |

| Limitations | Quantitative only (does not identify specific elements); assumes complete combustion. |

Ensure your materials meet the highest standards of quality and consistency. The ash content test is a fundamental step, and having the right equipment is crucial for accurate results. KINTEK specializes in high-quality lab furnaces and consumables designed for precise ashing procedures. Whether you're in plastics, food, pharmaceuticals, or materials science, our solutions help you verify specifications and maintain process control. Contact our experts today to find the perfect lab equipment for your quality control needs.

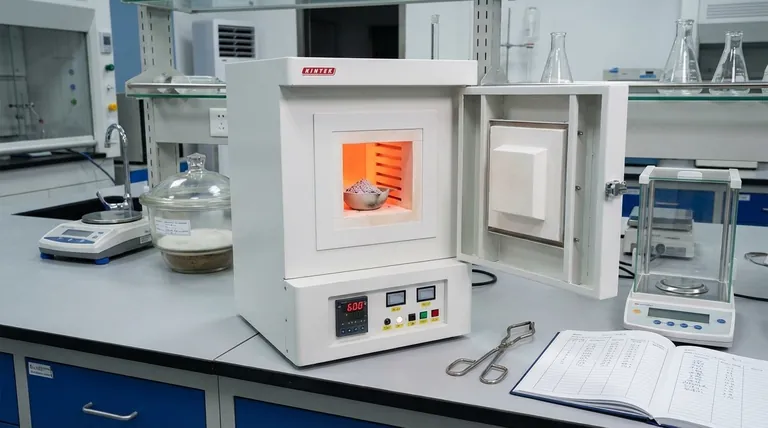

Visual Guide

Related Products

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- What is a muffle furnace used for in a lab? Achieve Clean, High-Temperature Processing

- What is the temperature range of a laboratory muffle furnace? Find the Right Model for Your Application

- Can calcination be done in a muffle furnace? Yes, for precise air-atmosphere heating.

- What is the precaution for muffle furnace? Essential Safety Protocols for Lab Excellence

- What are the classification of refractory materials? A Guide to Chemical and Thermal Selection