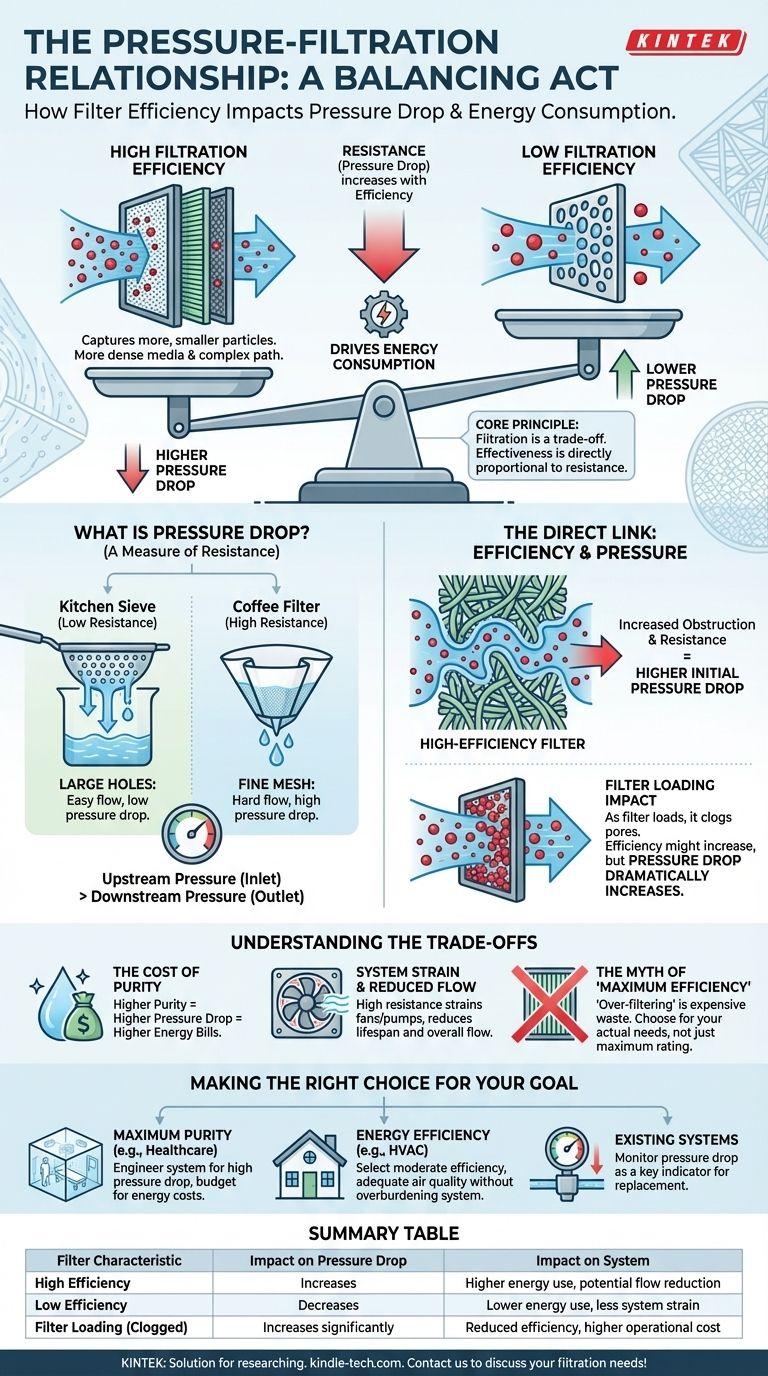

In filtration, pressure and efficiency are fundamentally linked. A higher filtration efficiency invariably results in a higher pressure drop. This means the more effective a filter is at capturing small particles, the more resistance it creates to the flow of the fluid (like air or water) passing through it, forcing your system to work harder.

The core principle to understand is that filtration is a balancing act. The effectiveness of a filter at capturing contaminants (its efficiency) is directly proportional to the resistance it creates (pressure drop), which in turn drives energy consumption and system performance.

What is Pressure Drop?

A Measure of Resistance

Pressure drop is the difference in pressure measured between the upstream (inlet) side and the downstream (outlet) side of a filter. It is the most direct way to quantify how much resistance a filter adds to a system.

An Intuitive Analogy

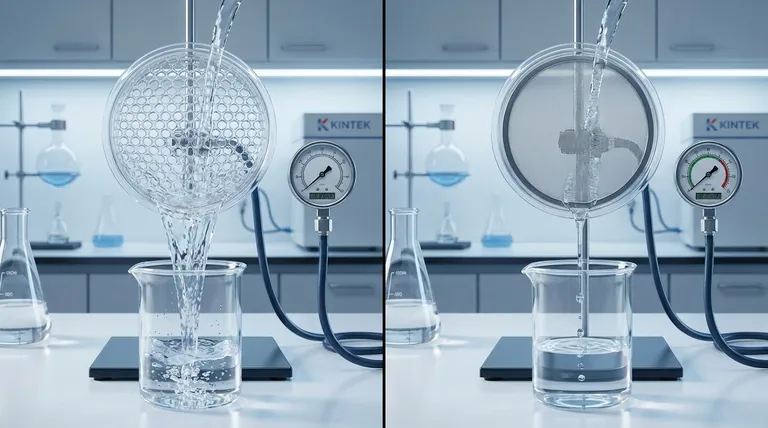

Think of pouring water through a kitchen sieve. A sieve with large holes allows water to flow through with little resistance—this is a low pressure drop. A sieve made of very fine mesh, like a coffee filter, requires more force to push the same amount of water through in the same amount of time. This resistance is a high pressure drop.

Why It Matters

A high pressure drop signifies that the system's fan or pump must exert more energy to move the fluid through the filter. This directly translates to higher energy consumption and can reduce the overall flow rate if the system isn't powerful enough to overcome the resistance.

The Direct Link Between Efficiency and Pressure

How High-Efficiency Filters Work

High-efficiency filters are designed to capture extremely small particles. To do this, their internal filter media is either much denser or creates a more complex, tortuous path for the fluid to navigate.

The Source of Resistance

This dense and complex structure, which is essential for capturing microscopic contaminants, naturally creates more physical obstruction. More obstruction means more resistance, leading directly to a higher initial pressure drop compared to a less efficient filter.

The Impact of Filter Loading

As any filter operates, it captures and holds contaminants. These trapped particles begin to clog the filter's pores, which ironically can increase its capture efficiency but also dramatically increases the pressure drop. This is why filters must be changed regularly.

Understanding the Trade-offs

The Cost of Purity

The central trade-off is between the quality of your filtered fluid and the operational cost. Achieving higher purity with a more efficient filter will always demand more energy to overcome the associated pressure drop, leading to higher utility bills.

System Strain and Reduced Flow

Forcing air or liquid through a high-resistance filter can put significant strain on fans, motors, and pumps, potentially reducing their operational lifespan. In systems not designed for it, a high-efficiency filter can starve the system, leading to a noticeable reduction in overall flow.

The Myth of "Always Choose Maximum Efficiency"

Selecting a filter with an efficiency rating that is much higher than what the application truly requires is a frequent and expensive error. This "over-filtering" leads to unnecessary energy expenditure and can negatively impact system performance without providing any tangible benefit.

Making the Right Choice for Your Goal

Ultimately, the correct filter is the one that meets your specific requirements without introducing excessive and costly resistance.

- If your primary focus is maximum purity (e.g., cleanrooms, healthcare): You must engineer the system to handle a high pressure drop and budget for the corresponding energy costs.

- If your primary focus is energy efficiency (e.g., residential HVAC): Select a filter with a moderate efficiency rating that provides adequate air quality without overburdening your system's fan.

- If you are managing an existing system: Monitor the pressure drop across your filters as a key indicator for when they are loaded and require replacement to maintain both efficiency and performance.

Choosing the right filter is about finding the optimal balance between performance and purity for your specific application.

Summary Table:

| Filter Characteristic | Impact on Pressure Drop | Impact on System |

|---|---|---|

| High Efficiency | Increases | Higher energy use, potential flow reduction |

| Low Efficiency | Decreases | Lower energy use, less system strain |

| Filter Loading (Clogged) | Increases significantly | Reduced efficiency, higher operational cost |

Struggling to balance filtration efficiency with system pressure and energy costs? KINTEK specializes in lab equipment and consumables, offering expert solutions to help you select the perfect filter for your specific application—ensuring optimal performance, purity, and cost-efficiency for your laboratory. Contact us today to discuss your filtration needs and let our specialists guide you to a smarter, more effective solution!

Visual Guide

Related Products

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Oil Free Diaphragm Vacuum Pump for Laboratory and Industrial Use

- Benchtop Laboratory Vacuum Freeze Dryer

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

People Also Ask

- Why is it important to autoclave the prepared reagents before using? Ensure Sterility and Reliable Results

- What are the sizes of autoclaves? A Guide to Choosing the Right Capacity for Your Lab

- How do you sterilize glassware by autoclave? Master the 3-Step Process for Reliable Sterility

- What temperature must be reached for sterilization in 10-12 minutes? Achieve Rapid, Reliable Sterility with Flash Autoclaving

- Can autoclave sterilize liquid? Master Safe and Effective Liquid Sterilization