In short, the refrigeration system is the heart of a freeze dryer, performing two distinct and critical functions. Its primary role is to first freeze the product you intend to dry. Then, during the drying process, it creates an extremely cold surface called a cold trap (or condenser) that captures the water vapor as it leaves the product, effectively removing it from the system.

The core purpose of the refrigeration system is not simply to make things cold, but to create a powerful temperature differential. This differential is essential for both solidifying the water in the product and for efficiently trapping that same water once it turns into a vapor.

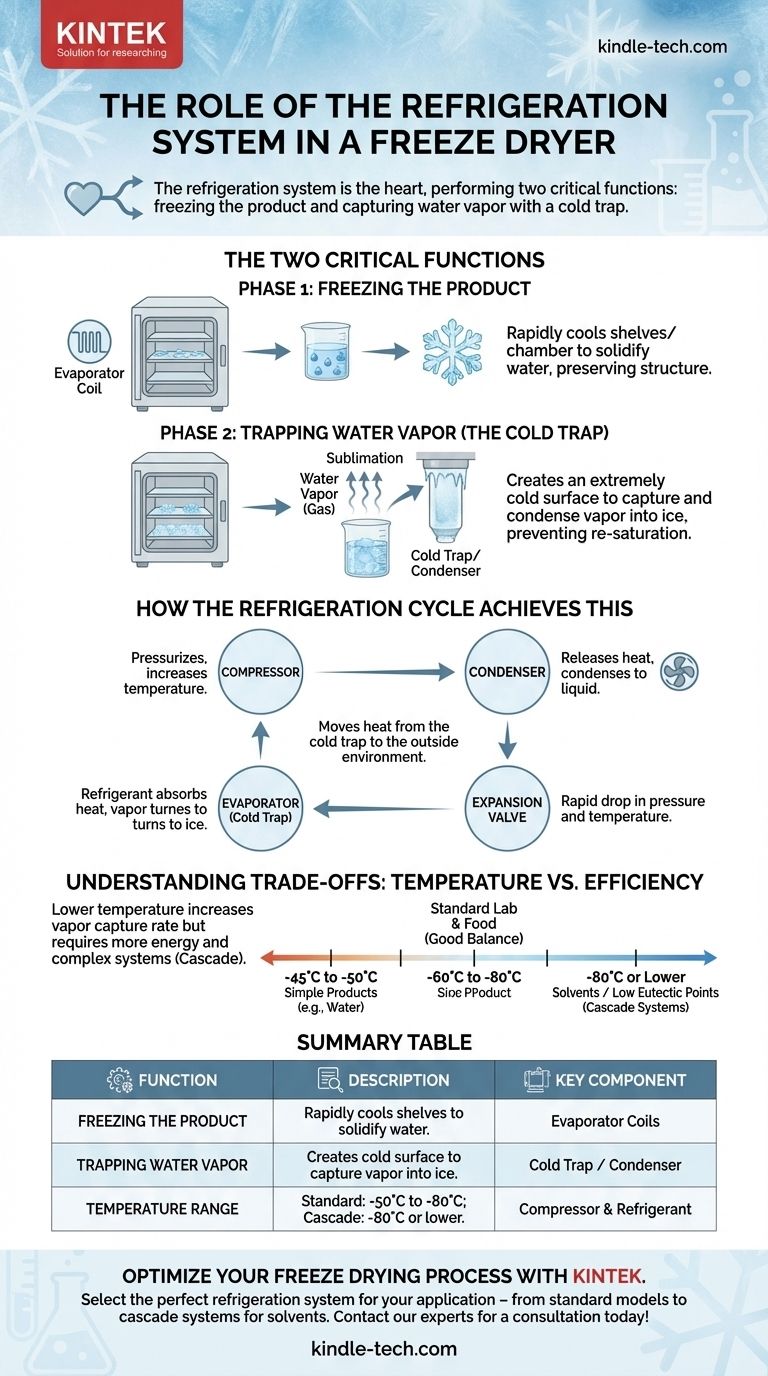

The Two Critical Functions of Refrigeration

A freeze dryer works by sublimation—turning solid ice directly into a gas (water vapor) under a vacuum. The refrigeration system is essential to making this process possible and efficient.

Phase 1: Freezing the Product

Before drying can begin, all the water within your material must be solidly frozen. The refrigeration system cools the shelves or the chamber to rapidly freeze the product.

This initial freezing step is critical. It locks the water molecules in place as ice crystals, preserving the product's structure at a microscopic level. Without a complete and solid freeze, the material would simply boil and be destroyed under vacuum.

Phase 2: Trapping Water Vapor (The Cold Trap)

Once the product is frozen and under vacuum, the sublimation process begins. As water vapor leaves the product, it must be removed from the chamber. This is the refrigeration system's most vital role.

The system chills a dedicated component, known as the cold trap or condenser, to a temperature far below that of the product. This extremely cold surface acts like a magnet for water vapor.

When the vapor molecules come into contact with the cold trap, they instantly turn back into solid ice, effectively trapping them. This prevents the vapor from re-saturating the product or overwhelming the vacuum pump, allowing the drying process to continue.

How the Refrigeration Cycle Achieves This

The system doesn't create cold; it is a heat pump that moves thermal energy from one place to another. This is achieved through a continuous cycle using a refrigerant.

The Basic Principle: Moving Heat

The refrigerant absorbs heat from the cold trap, causing the trap to become extremely cold. The system then transports this heat outside the freeze dryer chamber, where it is released into the ambient air.

Key Components in Action

- Evaporator: This is the part of the system connected to the cold trap. Here, the liquid refrigerant evaporates into a gas, absorbing a tremendous amount of heat and making the cold trap surface freeze.

- Compressor: This component pressurizes the low-pressure refrigerant gas, increasing its temperature significantly.

- Condenser: As the hot, high-pressure gas moves through the condenser coils (often cooled by a fan), it releases its heat to the surrounding environment and condenses back into a liquid.

- Expansion Valve: The high-pressure liquid refrigerant flows through this valve, causing a rapid drop in pressure and temperature before it re-enters the evaporator to repeat the cycle.

Understanding the Trade-offs: Temperature vs. Efficiency

The temperature of the cold trap is a critical parameter, but colder is not always universally better. The choice involves balancing performance with cost and energy consumption.

The Impact of Cold Trap Temperature

A lower cold trap temperature creates a larger temperature difference between the product and the trap, which increases the rate at which water vapor is captured. This can speed up the drying process.

Common cold trap temperatures are set based on the product being dried:

- -45°C to -50°C: Sufficient for simple products with high freezing points (like plain water).

- -60°C to -80°C: The standard for most lab and food applications, providing a good balance of efficiency and performance.

- -80°C or Lower: Necessary for products containing solvents or materials with very low freezing points (eutectic points). This often requires more complex cascade refrigeration systems, where two cooling circuits work together to achieve deeper cold.

The Cost of Deeper Cold

Reaching and maintaining lower temperatures demands more powerful compressors and more sophisticated system designs. This results in a higher initial equipment cost and significantly greater energy consumption during operation. Over-specifying a system for a simple task leads to unnecessary expense.

Making the Right Choice for Your Application

Selecting a freeze dryer with the appropriate refrigeration system depends entirely on your specific materials and goals.

- If your primary focus is general-purpose lab work or food preservation: A standard system with a -50°C to -80°C cold trap is the most versatile and cost-effective choice.

- If you are working with solvents or materials with low eutectic points: A more powerful cascade refrigeration system capable of reaching -80°C or lower is non-negotiable for effective vapor trapping.

- If your priority is maximizing energy efficiency for simple aqueous samples: A system designed to operate around -50°C will be sufficient and consume less power than a more powerful unit.

Understanding the refrigeration system's dual role empowers you to select and operate your freeze dryer with maximum efficiency and precision.

Summary Table:

| Function | Description | Key Component |

|---|---|---|

| Freezing the Product | Rapidly cools shelves to solidify all water into ice, preserving product structure. | Evaporator Coils |

| Trapping Water Vapor | Creates an extremely cold surface (cold trap) to capture and condense vapor into ice. | Cold Trap / Condenser |

| Temperature Range | Standard: -50°C to -80°C; Cascade for solvents: -80°C or lower. | Compressor & Refrigerant |

Optimize Your Freeze Drying Process with KINTEK

Understanding the critical role of the refrigeration system is the first step to achieving perfect results. Whether you are preserving sensitive biological samples, developing pharmaceuticals, or creating shelf-stable foods, selecting the right freeze dryer is paramount.

KINTEK specializes in high-quality lab equipment, including freeze dryers with refrigeration systems tailored to your specific application. We can help you choose the ideal system—from standard models for aqueous solutions to powerful cascade systems for solvents—ensuring efficiency, precision, and cost-effectiveness.

Let our experts guide you to the perfect solution for your laboratory needs. Contact KINTEK today for a consultation and discover how our reliable equipment can enhance your research and production.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis

- What are the three primary stages of the freeze-drying process? Master Precise Lyophilization for Your Lab

- What are the hazards of evaporators? Manage Chemical, Thermal, and Pressure Risks

- What are the cost considerations for freeze drying? Uncover the 90% Hidden Operational Expenses

- In which fields is the laboratory freeze dryer commonly used? Essential for Biopharma, Food Science & Research