At its core, freeze-drying is a critical tool in environmental studies because it offers the most effective method for preserving the biological and chemical integrity of samples. Unlike simple drying or chemical fixation, this process, also known as lyophilization, removes water without significantly damaging the sample's physical structure or altering its composition, ensuring that subsequent analyses are accurate and reliable.

The true significance of freeze-drying lies in its ability to halt time. By removing water through sublimation, it locks a sample in a state of suspended animation, preserving its delicate structure and chemical makeup for precise scientific investigation.

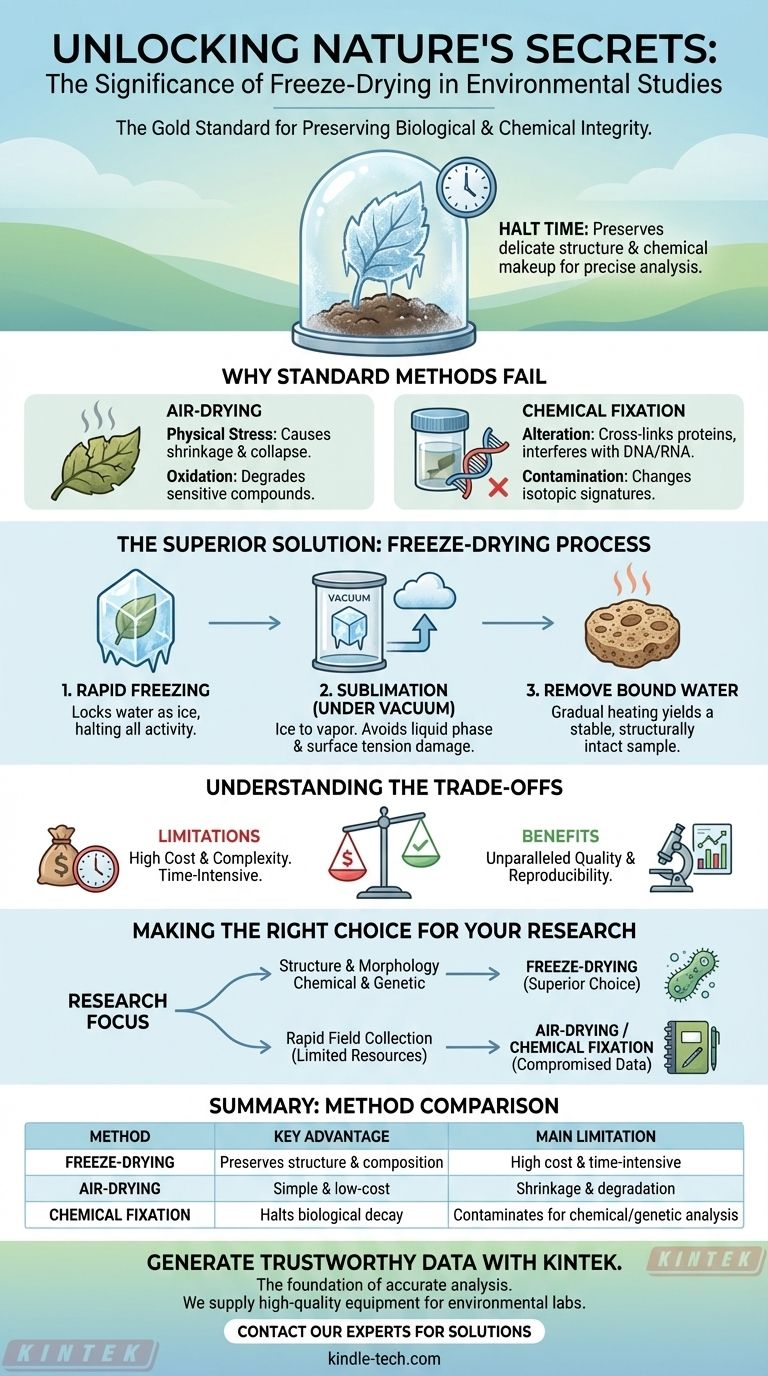

Why Standard Preservation Methods Often Fail

Before understanding the value of freeze-drying, it's essential to recognize the limitations of conventional preservation techniques used in environmental science.

The Problem with Air-Drying

Air-drying is simple and cheap, but it causes significant physical stress. As water evaporates, surface tension causes cells to shrink and collapse, permanently altering the sample's original structure and porosity.

This method also exposes the sample to oxygen for extended periods at moderate temperatures, which can lead to oxidation and the degradation of sensitive chemical compounds.

The Drawbacks of Chemical Fixation

Using chemicals like formalin or ethanol can halt biological decay, but they fundamentally change the sample. These fixatives can cross-link proteins, interfere with genetic material (DNA/RNA), and alter the isotopic signatures that are crucial for many environmental analyses.

Essentially, the act of preserving the sample with chemicals contaminates it for many of the tests scientists need to run.

How Freeze-Drying Achieves Superior Preservation

Freeze-drying is a multi-step process engineered to bypass the damaging effects of other methods. It works by gently removing water while the sample is in a frozen state.

Step 1: Rapid Freezing

First, the sample is rapidly frozen. This locks water molecules in place as ice crystals, instantly preserving the sample's physical structure and halting all biological and most chemical activity.

Step 2: Sublimation Under Vacuum

The frozen sample is then placed in a vacuum chamber. The pressure is lowered significantly, and a small amount of heat is added, causing the ice to turn directly into water vapor without first melting into a liquid.

This process, called sublimation, is the key. By avoiding the liquid phase, the powerful surface tension of water is eliminated, preventing the cellular collapse and shrinkage seen in air-drying.

Step 3: Removing Bound Water

Finally, the temperature is gradually increased to remove any remaining water molecules that were chemically bound to the sample material. The result is a lightweight, structurally intact, and chemically stable sample.

Understanding the Trade-offs

While freeze-drying is the gold standard for many applications, it is not without its limitations. Objectivity requires acknowledging these factors.

High Cost and Complexity

Freeze-drying equipment is expensive to purchase and maintain. The process also requires specialized knowledge to operate correctly, making it less accessible for field researchers with limited budgets or facilities.

Time-Intensive Process

Lyophilization is not fast. Depending on the size and water content of the sample, a single run can take anywhere from several hours to several days to complete. This is a significant consideration for high-throughput studies.

Making the Right Choice for Your Research

Choosing a preservation method depends entirely on the data you need to collect. The method you use on-site determines the quality of questions you can answer in the lab.

- If your primary focus is structural or morphological analysis: Freeze-drying is unparalleled for preserving the delicate, three-dimensional features of plants, soils, or biological tissues.

- If your primary focus is chemical, isotopic, or genetic analysis: Freeze-drying is the superior choice to prevent contamination and degradation of the very molecules you intend to study.

- If your primary focus is rapid field collection with limited resources: Air-drying or chemical fixation may be your only options, but you must acknowledge and account for the potential data compromises in your final analysis.

Ultimately, employing the right preservation technique is the foundational step toward generating trustworthy and reproducible environmental data.

Summary Table:

| Method | Key Advantage | Main Limitation |

|---|---|---|

| Freeze-Drying | Preserves physical structure & chemical composition | High cost and time-intensive |

| Air-Drying | Simple and low-cost | Causes sample shrinkage and degradation |

| Chemical Fixation | Halts biological decay | Contaminates sample for chemical/genetic analysis |

Generate Trustworthy Environmental Data with KINTEK

The right preservation technique is the foundation of accurate analysis. For researchers who cannot compromise on sample integrity, KINTEK provides the reliable lab equipment you need.

We specialize in supplying environmental science laboratories with high-quality equipment and consumables. Let us help you ensure your samples are preserved perfectly for structural, chemical, isotopic, and genetic analysis.

Contact our experts today to find the ideal preservation solution for your specific research needs.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

People Also Ask

- How much can proper freeze drying reduce drying times? Cut Drying Time by Up to 30%

- What precautions should be taken when using a laboratory freeze dryer? Essential Steps for Reliable Lyophilization

- What types of pharmaceutical products are commonly produced using freeze drying technology? Essential for Vaccines & Biologics

- What happens during the freezing phase of lyophilization? Master the Critical First Step for Product Integrity

- What are the advantages of using a Laboratory Freeze Dryer? Preserve Sample Integrity with Lyophilization