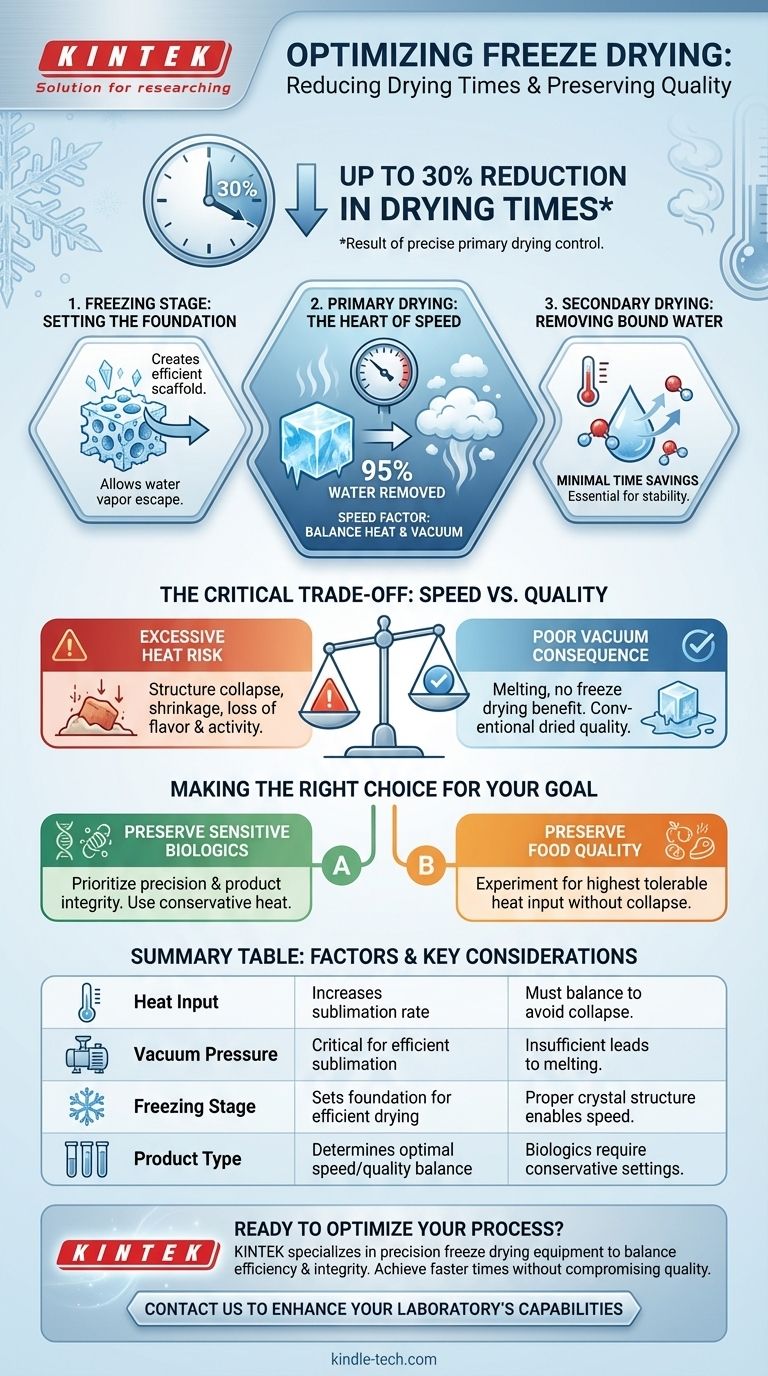

Properly managed freeze drying can reduce drying times by up to 30%. This efficiency gain is not automatic; it results from a precise understanding and control of the process, particularly the primary drying phase where the bulk of water is removed through sublimation.

The core principle of faster freeze drying is maximizing the rate of sublimation without damaging the product's structure. This is achieved by carefully balancing heat input and vacuum pressure during the primary drying stage.

The Science Behind Freeze-Drying Speed

Freeze drying, or lyophilization, is a multi-stage process. While the entire sequence is important, the potential for significant time savings lies almost entirely within the primary drying phase.

The Freezing Stage: Setting the Foundation

The first step is to completely freeze the material. The way a product is frozen creates the ice crystal structure that will act as a scaffold.

A well-executed freezing stage results in a crystal structure that allows water vapor to escape more easily during the subsequent drying phase, setting the stage for efficiency.

Primary Drying: The Heart of the Process

This is the longest and most critical stage, where about 95% of the water is removed. The process, known as sublimation, turns solid ice directly into water vapor under a deep vacuum.

The speed of sublimation is dictated by two key factors: the amount of heat added to the product and the strength of the vacuum. Proper control here is what unlocks the 30% time reduction.

Secondary Drying: Removing Bound Water

After primary drying, a small amount of water remains chemically bound to the material. This final stage uses slightly higher temperatures and a stronger vacuum to remove this residual moisture.

While essential for long-term stability, this phase offers minimal opportunity for significant time savings compared to primary drying.

The Critical Trade-off: Speed vs. Quality

Pushing for maximum speed without understanding the underlying principles can compromise or even destroy the product. The entire purpose of freeze drying is to preserve quality, a goal that can be at odds with pure speed.

The Risk of Excessive Heat

The primary way to speed up drying is to add more heat energy. However, if too much heat is applied, it can overwhelm the sublimation process.

This can cause the product's structure to collapse or melt, resulting in shrinkage, discoloration, and loss of the very characteristics—like flavor, texture, and biological activity—that freeze drying is meant to preserve.

The Consequence of a Poor Vacuum

A deep and consistent vacuum is non-negotiable. It lowers the boiling point of water, allowing sublimation to occur at low temperatures.

If the vacuum is insufficient, the ice may melt into liquid water instead of turning into vapor. This negates the benefits of freeze drying and results in a product with the quality of a conventionally dried item.

Making the Right Choice for Your Goal

Optimizing freeze drying is about finding the sweet spot for your specific material, balancing speed against the absolute need for quality preservation.

- If your primary focus is preserving sensitive biologics (vaccines, proteins): Prioritize precision and product integrity over speed, using conservative heat settings to guarantee preservation of biological activity.

- If your primary focus is preserving food quality (flavor, texture, color): Experiment to find the highest possible heat input your specific product can tolerate during primary drying without showing signs of structural collapse.

Mastering this balance is the key to achieving both efficient drying times and a superior final product.

Summary Table:

| Factor | Impact on Drying Time | Key Consideration |

|---|---|---|

| Heat Input | Increases sublimation rate | Must be balanced to avoid product collapse |

| Vacuum Pressure | Critical for efficient sublimation | Insufficient vacuum leads to melting |

| Freezing Stage | Sets foundation for efficient drying | Proper ice crystal structure enables faster drying |

| Product Type | Determines optimal speed/quality balance | Sensitive biologics require more conservative settings |

Ready to optimize your freeze drying process? KINTEK specializes in precision lab equipment and consumables for laboratories seeking to balance efficiency with product integrity. Our expertise in freeze drying technology can help you achieve faster drying times while maintaining the highest quality standards for your sensitive materials. Contact us today to discuss how we can enhance your laboratory's freeze drying capabilities!

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing

- What role does a laboratory freeze dryer play in the synthesis of graphene-based electrocatalysts? Preserve 3D Structures

- Why is a laboratory vacuum freeze dryer essential for plant extracts? Preserve Bioactivity & Structure

- What is the function of a freeze dryer in the ice-templating process? Preserving Aligned Pore Scaffolds for LAGP

- Why is a freeze dryer preferred for reduced graphene oxide (Hh-RGO) powders? Preserve Nano-Structure and Performance