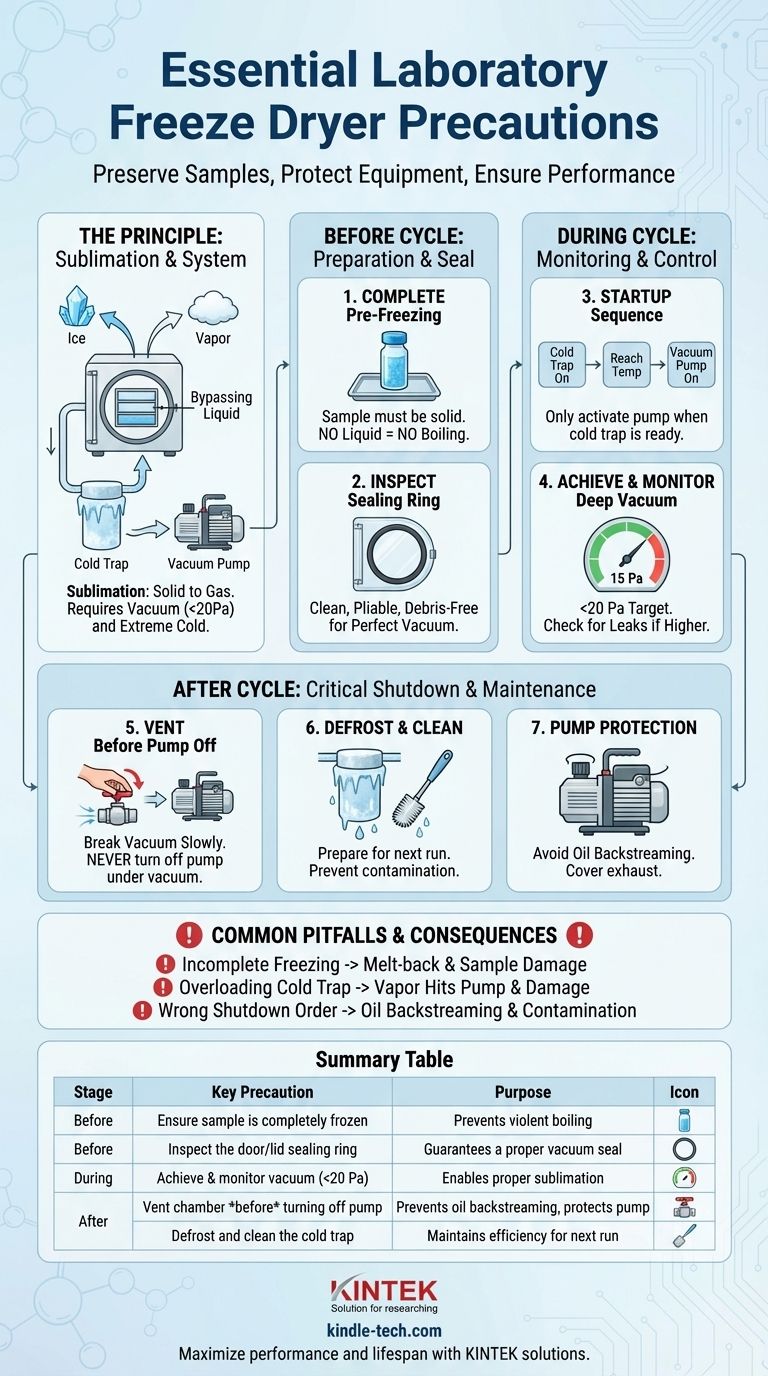

Properly using a laboratory freeze dryer requires a sequence of specific precautions before, during, and after the cycle. Key steps include ensuring the sample is completely frozen before starting, inspecting the door or lid's sealing ring for integrity, achieving and monitoring a deep vacuum (typically below 20Pa), and following a precise shutdown procedure that involves venting the system before turning off the vacuum pump.

A freeze dryer is not a simple appliance; it is a precision system. The precautions are not merely suggestions—they are fundamental rules for protecting the integrity of your sample, the performance of the vacuum, and the long-term health of the equipment itself.

The Principle of Operation: Why Precautions Matter

A laboratory freeze dryer, or lyophilizer, works by removing water from a frozen sample through a process called sublimation.

Sublimation is the direct transition of a substance from a solid (ice) to a gas (water vapor), bypassing the liquid phase. This preserves the sample's delicate structure, from proteins to pharmaceuticals.

The Role of Vacuum and Cold

To achieve sublimation, the system relies on two critical components.

The vacuum pump lowers the pressure inside the chamber well below water's "triple point." At this low pressure, ice can no longer melt into a liquid and will turn directly into vapor.

The cold trap (or condenser) is a surface cooled to an extremely low temperature. As water vapor leaves the sample, it travels to the even colder trap and freezes onto it, effectively removing it from the system and preventing it from damaging the vacuum pump.

A Step-by-Step Guide to Safe Operation

Following the correct operational sequence is the most effective precaution you can take. Each step is designed to enable the principle of sublimation and protect the system's components.

Before You Begin: Preparation is Key

Your primary goal here is to ensure the sample is a stable solid and the system is sealed.

First, pre-freeze your material completely. The sample must be solidly frozen before being placed under vacuum. If it contains any liquid, it will boil violently under vacuum, damaging the sample's structure and potentially contaminating the chamber.

Next, inspect the sealing ring on the plexiglass cover or chamber door. It must be clean, pliable, and free of any nicks or debris to ensure a perfect vacuum seal.

Finally, place your pre-frozen materials onto the drying rack inside the chamber and ensure the drain valve is tightly closed.

During the Cycle: Monitoring the Process

This phase is about creating and maintaining the conditions for sublimation.

Turn on the refrigeration for the cold trap and wait for it to reach its target temperature. Only then should you turn on the vacuum pump.

Monitor the vacuum gauge closely. A properly sealed and functioning system should reach a deep vacuum, often specified as less than 20 Pascals (Pa). A failure to reach this level indicates a leak or an issue with the pump.

Once the vacuum is stable, you can open any necessary valves (like those on a multi-manifold) to connect flasks to the system.

After the Cycle: Proper Shutdown and Maintenance

The shutdown sequence is the most critical moment for protecting the vacuum pump.

First, close the valves that isolate your sample containers from the main chamber.

Next, you must break the vacuum. Open the designated intake or vent valve to slowly allow air back into the chamber. Never turn off the pump while the system is under vacuum.

Only after the chamber has returned to atmospheric pressure should you turn off the vacuum pump. This prevents air and moisture from rushing back through the pump and contaminating the pump oil.

Finally, power down the system, defrost and clean the cold trap, and cover the vacuum pump's exhaust port to prevent dust from entering.

Common Pitfalls to Avoid

Mistakes during lyophilization are costly, leading to failed runs and equipment damage.

Pitfall: Incomplete Pre-Freezing

If a sample is not fully frozen, it will undergo "melt-back" or boil under vacuum. This destroys the fine, porous structure that freeze-drying is meant to create, resulting in a collapsed, unusable product.

Pitfall: Overloading the Cold Trap

The cold trap has a maximum capacity for holding ice. If you try to dry too large a volume of water at once, the trap cannot condense the vapor fast enough. This vapor will bypass the trap and flow directly into the expensive vacuum pump, causing severe damage.

Pitfall: Shutting Down in the Wrong Order

Turning off the vacuum pump before venting the chamber is a catastrophic error. The low pressure in the chamber will suck oil out of the pump and back into the system, contaminating the chamber and your next run. This is known as oil "backstreaming."

Making the Right Choice for Your Goal

Adhering to these precautions ensures you achieve the desired outcome for your specific application.

- If your primary focus is preserving sensitive biologics: Your highest priority is ensuring a deep, stable vacuum and complete pre-freezing to prevent any melt-back that could denature the product.

- If your primary focus is high throughput and efficiency: Diligent post-cycle maintenance is key. A fast defrost and clean of the cold trap allows you to prepare for the next run quickly and reliably.

- If your primary focus is equipment longevity: Master the shutdown procedure. Always vent the system before deactivating the pump to protect its most critical and expensive component.

By treating these precautions as integral to the scientific process, you will ensure consistent, reproducible results and a long, reliable life for your freeze dryer.

Summary Table:

| Stage | Key Precaution | Purpose |

|---|---|---|

| Before | Ensure sample is completely frozen | Prevents violent boiling and sample damage |

| Before | Inspect the door/lid sealing ring | Guarantees a proper vacuum seal |

| During | Achieve & monitor vacuum (<20 Pa) | Enables proper sublimation |

| After | Vent chamber before turning off pump | Prevents oil backstreaming, protects pump |

| After | Defrost and clean the cold trap | Maintains efficiency for the next run |

Maximize the performance and lifespan of your lab equipment with KINTEK.

Following these freeze-drying precautions is essential for protecting your sensitive samples and your investment. At KINTEK, we specialize in providing reliable laboratory equipment and consumables, including freeze dryers designed for precise control and durability. Our experts can help you select the right system for your application—whether you're preserving delicate biologics, developing pharmaceuticals, or processing food samples—and ensure your team is trained on best practices.

Let KINTEK be your partner in achieving consistent, reproducible results.

Contact our team today to discuss your specific laboratory needs and discover how our solutions can enhance your workflow.

Visual Guide

Related Products

- Benchtop Laboratory Freeze Dryer for Lab Use

- Benchtop Laboratory Vacuum Freeze Dryer

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Test Sieves and Sieving Machines

People Also Ask

- Why is a freeze dryer preferred for drying nickel nanoparticle precursors? Prevent Hard Agglomeration Now

- What are the advantages of using freeze drying for phase change materials with biopolymer shells? Optimize Stability

- Why is a freeze dryer preferred for reduced graphene oxide (Hh-RGO) powders? Preserve Nano-Structure and Performance

- Why is a laboratory freeze-drying system essential for fermentation biomass? Preserve Sample Integrity for Analysis

- Why is a freeze dryer preferred over thermal drying for Fe-ZTA cermets? Ensure Pure, Homogeneous Slurry Processing