There is no single "standard" heat treatment process. Instead, heat treatment is a highly engineered methodology tailored to achieve a specific outcome for a given material. The process used is entirely dependent on the desired physical properties of the final part, such as hardness, toughness, or internal stress levels.

Heat treatment is not a uniform recipe but a framework consisting of three core stages—heating, soaking, and cooling. The "standard" lies in this framework, while the variables within each stage are precisely controlled to deliberately alter a material's internal microstructure and achieve a specific engineering goal.

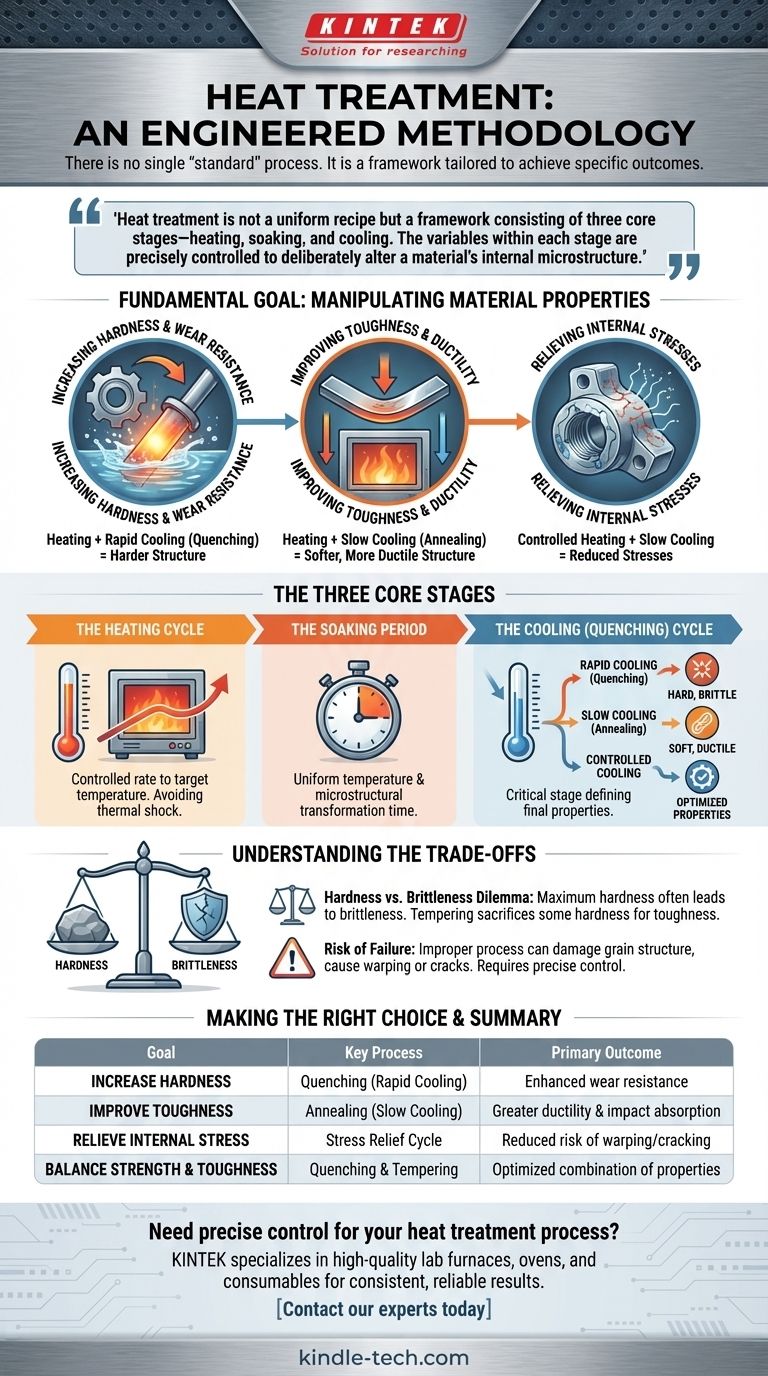

The Fundamental Goal: Manipulating Material Properties

Heat treatment is fundamentally about changing a material’s internal structure to enhance its properties for a specific application. This is especially critical for metals like steel, where minor adjustments to the treatment process can produce dramatically different performance characteristics.

Increasing Hardness and Wear Resistance

One of the most common goals is to make a material harder. This is achieved by heating the metal to a specific temperature to alter its crystal structure and then cooling it rapidly (quenching) to lock that hard structure in place. This improves a part's resistance to wear, abrasion, and indentation.

Improving Toughness and Ductility

Conversely, a material may be too brittle for its intended use. Processes like annealing involve heating a metal and then cooling it very slowly. This rearranges the material's internal structure to be more uniform and less stressed, increasing its ability to deform without fracturing (ductility) and absorb impact (toughness).

Relieving Internal Stresses

Manufacturing processes like welding, casting, or machining introduce significant internal stresses into a material. These stresses can lead to warping or cracking over time. A stress-relief heat cycle involves heating the part to a temperature below its transformation point and then slowly cooling it, which allows these internal forces to relax without changing the core properties.

Enhancing Other Properties

Beyond mechanical changes, heat treatment can also refine a material's electrical and magnetic properties. This is critical for components used in electric motors, transformers, and other electromagnetic applications.

The Three Core Stages of Any Heat Treatment

While the specific temperatures, times, and cooling rates vary enormously, virtually all heat treatment processes follow a three-stage structure. Mastering a process means mastering the variables in each stage.

Stage 1: The Heating Cycle

The part is heated in a controlled manner to a target temperature. The rate of heating is important; heating too quickly can cause thermal shock and cracking, especially in complex geometries. The target temperature is determined by the material and the desired final properties.

Stage 2: The Soaking Period

Once at the target temperature, the material is held, or "soaked," for a specific amount of time. This period allows the temperature to become uniform throughout the part and gives the internal microstructure the time it needs to fully transform. The soaking time depends on the material's chemistry and the part's cross-sectional thickness.

Stage 3: The Cooling (Quenching) Cycle

This is often the most critical stage. The rate at which the material is cooled from the soaking temperature dictates its final microstructure and, therefore, its mechanical properties. Rapid cooling in water, oil, or forced air (quenching) creates a hard, brittle structure, while very slow cooling inside a furnace (annealing) creates a soft, ductile structure.

Understanding the Trade-offs

Heat treatment is not a magic bullet; it is an engineering compromise. Improving one property almost always comes at the expense of another.

The Hardness vs. Brittleness Dilemma

The most common trade-off is between hardness and toughness. A material that is heat-treated to achieve maximum hardness will almost always be extremely brittle and prone to shattering under impact. This is why extremely hard parts are often subsequently tempered—reheated to a lower temperature—to sacrifice some hardness in exchange for a necessary increase in toughness.

The Risk of Failure

An improperly executed heat treatment is worse than no treatment at all. Overheating can permanently damage the material's grain structure, while incorrect cooling can introduce new stresses, cause warping, or create cracks. The process requires precise control and a deep understanding of the material's metallurgy.

Making the Right Choice for Your Goal

The correct heat treatment process is the one that achieves the specific properties your application demands. Always start by defining your end goal.

- If your primary focus is maximum hardness and wear resistance: You will need a process involving rapid quenching, such as case hardening or through-hardening, likely followed by a low-temperature tempering.

- If your primary focus is relieving stress for machinability: You will need a process with very slow cooling, such as annealing or normalizing, to produce a soft and uniform microstructure.

- If your primary focus is a balance of strength and toughness: You will likely need a two-step process of quenching to harden the part, followed by tempering to reduce brittleness and achieve the desired toughness.

Ultimately, selecting the right process begins with a clear understanding of what you need the material to do.

Summary Table:

| Goal | Key Process | Primary Outcome |

|---|---|---|

| Increase Hardness | Quenching (Rapid Cooling) | Enhanced wear resistance |

| Improve Toughness | Annealing (Slow Cooling) | Greater ductility and impact absorption |

| Relieve Internal Stress | Stress Relief Cycle | Reduced risk of warping or cracking |

| Balance Strength & Toughness | Quenching & Tempering | Optimized combination of properties |

Need precise control for your heat treatment process? The right lab equipment is critical for achieving consistent, reliable results. KINTEK specializes in high-quality lab furnaces, ovens, and consumables that provide the exact temperature control and uniformity your heat treatment applications demand.

Contact our experts today to discuss how our solutions can help you achieve your specific material property goals.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the two step sintering method? Achieve High Density with Fine Grain Structure

- How do you prepare samples for SEM analysis? Achieve Clear, Accurate Imaging Every Time

- What is debinding in additive manufacturing? The Critical Step for Strong Metal Parts

- How does heat treatment affect mechanical properties? A Guide to Optimizing Strength, Toughness, and Durability

- What is the difference between burning and pyrolysis? Unlock Value from Waste Materials

- Why are ULT freezers considered vital equipment in labs? Ensuring Uncompromised Sample Integrity for Critical Research

- How does the temperature control of a laboratory oven affect bimetallic catalysts? Ensure Optimal Metal Dispersion

- How does a laboratory magnetic stirrer contribute to pre-mixing? Master Your Photocatalytic Reaction Baselines