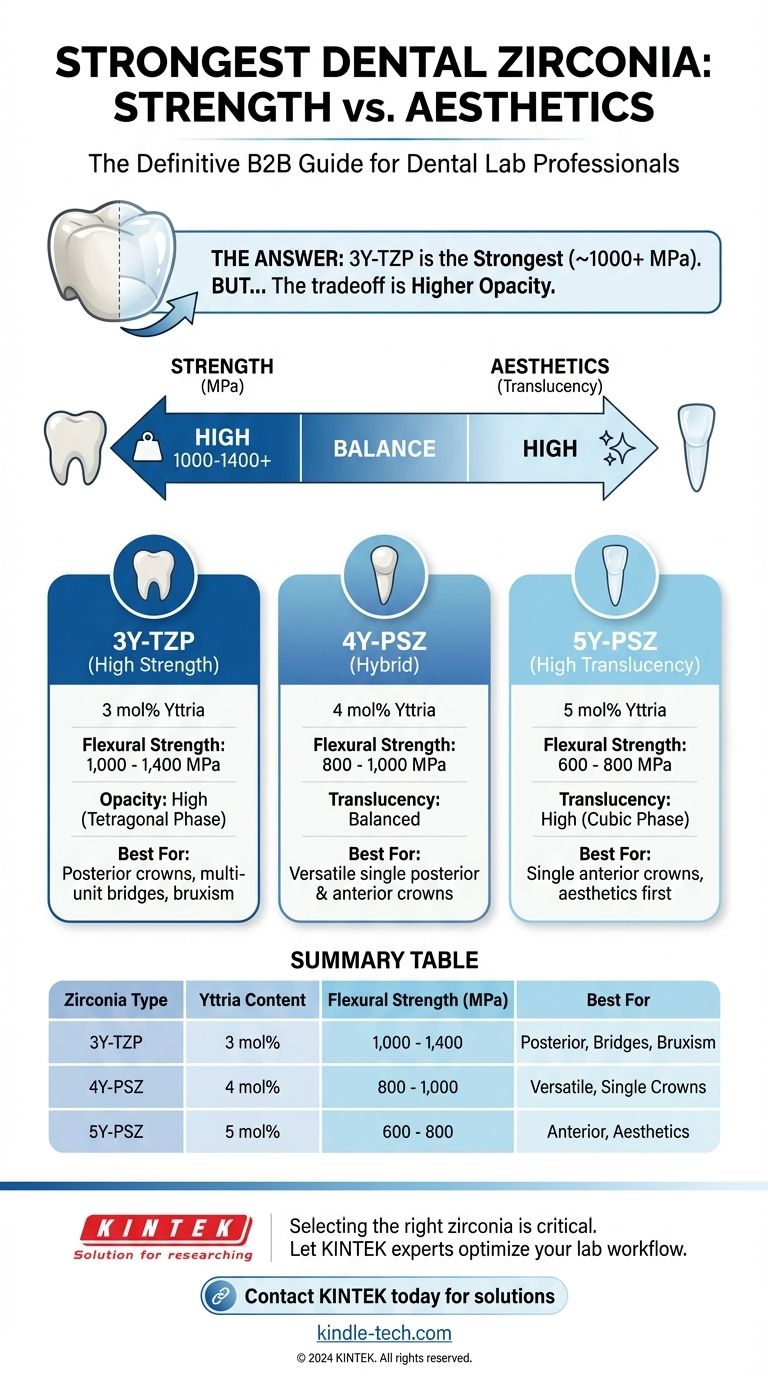

In terms of pure flexural strength, the strongest type of dental zirconia is 3Y-TZP (3 mol% yttria-stabilized tetragonal zirconia polycrystal). This original zirconia formulation boasts a flexural strength often exceeding 1,000 MPa, providing exceptional resistance to fracture. It is the material of choice for dental restorations placed in the highest-stress areas of the mouth.

The central challenge with zirconia is not identifying the "strongest" type, but rather understanding the inverse relationship between strength and aesthetics. The strongest zirconia formulations are also the most opaque, making them less suitable for anterior restorations. The optimal material is always dictated by the specific clinical need.

Deconstructing Zirconia: Why "Strength" Isn't the Whole Story

To make an informed decision, you must first understand that "zirconia" is not one single material. It is a family of advanced ceramics whose properties are precisely controlled by a key ingredient: yttria.

The Role of Yttria Stabilization

Zirconia in its pure form is unstable at room temperature. To be used in dentistry, it must be stabilized by adding small amounts of yttrium oxide, or yttria.

The percentage of yttria is the primary dial that a manufacturer turns to change the material's final properties. Small changes in yttria content have a dramatic effect on both strength and appearance.

Crystal Phases: Tetragonal vs. Cubic

The amount of yttria determines the material's internal crystal structure. This is the core principle you need to grasp.

- Tetragonal Phase: Formulations with low yttria content (like 3Y-TZP) are predominantly tetragonal. This crystal structure is incredibly strong and tough but scatters light, resulting in high opacity.

- Cubic Phase: As yttria content increases (to 4% or 5%), a significant portion of the crystals shift to a cubic phase. This structure is less strong but allows more light to pass through, resulting in higher translucency.

Measuring Strength: Flexural Strength (MPa)

When we discuss the "strength" of zirconia, we are typically referring to its flexural strength, measured in megapascals (MPa). This value represents how much force a material can withstand before it bends or fractures.

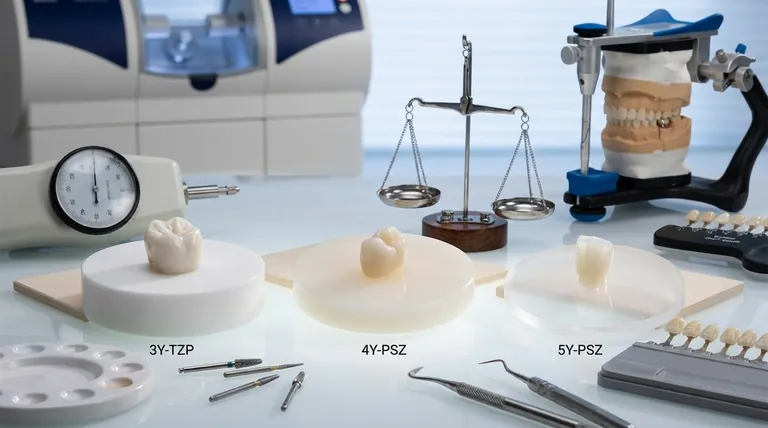

A Spectrum of Zirconia: From Powerhouse to Aesthetic

Modern zirconia exists on a spectrum, with each class designed for a specific purpose.

The Workhorse: 3Y-TZP (High Strength)

This is the strongest class of zirconia, with flexural strengths typically ranging from 1,000 to 1,400 MPa.

Its high opacity and supreme strength make it the undisputed choice for posterior crowns, multi-unit bridges, and restorations for patients with heavy biting forces (bruxism).

The Aesthetic Choice: 5Y-PSZ (High Translucency)

Often marketed as "anterior zirconia," this class contains around 5 mol% yttria. This creates a high percentage of cubic-phase crystals, providing excellent translucency that rivals other aesthetic ceramics.

This beauty comes at the cost of strength, which is significantly lower, typically in the range of 600 to 800 MPa. It is ideal for single anterior crowns where aesthetics are the primary concern.

The Hybrid Solution: 4Y-PSZ (The All-Rounder)

Sitting between the two extremes, 4Y-PSZ zirconia offers a balanced profile. It provides good strength, often 800 to 1,000 MPa, while offering significantly better translucency than the ultra-strong 3Y-TZP.

This makes it a highly versatile material suitable for a wide range of applications, including single posterior crowns and short-span bridges where improved aesthetics are desired.

Understanding the Trade-offs

Choosing the right zirconia requires a clear-eyed assessment of the compromises involved. You cannot have maximum strength and maximum translucency in a single monolithic material.

The Inherent Compromise

As yttria content increases to improve aesthetics, fracture toughness and flexural strength decrease. The highly aesthetic 5Y zirconia is roughly half as strong as the 3Y powerhouse.

This is the fundamental trade-off: you are always balancing mechanical performance against optical properties.

Wear on Opposing Teeth

A common concern with strong ceramics is the potential for wear on the opposing natural teeth. However, modern research shows this is a function of surface smoothness, not material strength.

A properly glazed and polished zirconia restoration, regardless of its strength class (3Y, 4Y, or 5Y), is exceptionally smooth and very kind to the opposing dentition.

Cementation Requirements

The material's strength influences how it should be secured to the tooth. Ultra-strong, opaque 3Y-TZP restorations can often be placed with conventional cement.

Weaker, more translucent 5Y-PSZ restorations benefit from being adhesively bonded. The bonding process integrates the restoration with the tooth, increasing the overall strength of the entire system.

Selecting the Right Zirconia for the Clinical Goal

Your material choice should not be based on a single property like strength, but on the specific demands of the restoration.

- If your primary focus is maximum durability (e.g., a posterior bridge or for a patient with bruxism): Choose a high-strength 3Y-TZP formulation for its superior fracture resistance.

- If your primary focus is supreme aesthetics (e.g., a single anterior crown): Opt for a high-translucency 5Y-PSZ material to achieve the most natural look.

- If you need a versatile solution for most standard posterior crowns: A hybrid 4Y-PSZ zirconia provides an excellent balance of reliable strength and enhanced aesthetics.

Understanding this spectrum empowers you to move beyond simply asking "what is strongest" and instead select the material that ensures the best possible clinical outcome.

Summary Table:

| Zirconia Type | Yttria Content | Key Feature | Flexural Strength (MPa) | Best For |

|---|---|---|---|---|

| 3Y-TZP | 3 mol% | Maximum Strength | 1,000 - 1,400 | Posterior crowns, bridges, bruxism |

| 4Y-PSZ | 4 mol% | Balanced Strength & Aesthetics | 800 - 1,000 | Versatile posterior & anterior crowns |

| 5Y-PSZ | 5 mol% | High Translucency | 600 - 800 | Anterior crowns where aesthetics are key |

Selecting the right zirconia is critical for successful dental restorations. At KINTEK, we specialize in providing high-quality dental lab equipment and consumables to support your laboratory's needs. Whether you're milling ultra-strong 3Y-TZP for posterior bridges or highly aesthetic 5Y-PSZ for anterior crowns, our solutions ensure precision and reliability. Let our experts help you optimize your workflow and achieve superior results. Contact KINTEK today to discuss how we can support your laboratory's specific requirements.

Visual Guide

Related Products

- Precision Machined Yttria Stabilized Zirconia Ceramic Plate for Engineering Advanced Fine Ceramics

- Precision Machined Yttrium Stabilized Zirconia Ceramic Rod for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Custom-Made Alumina Zirconia Special-Shaped Ceramic Plates for Engineering Advanced Fine Ceramics Processing

People Also Ask

- What is a furnace refractory? The Critical Lining for Safe, Efficient Furnace Operation

- What is the strongest zirconia phase? Tetragonal Zirconia Offers Unmatched Toughness

- How many types of hardening techniques are there? A Multi-Layered Security Strategy Explained

- What is the insulating material used in furnace? Achieve Peak Thermal Efficiency & Stability

- What material is used in refractory? A Guide to High-Temperature Material Selection