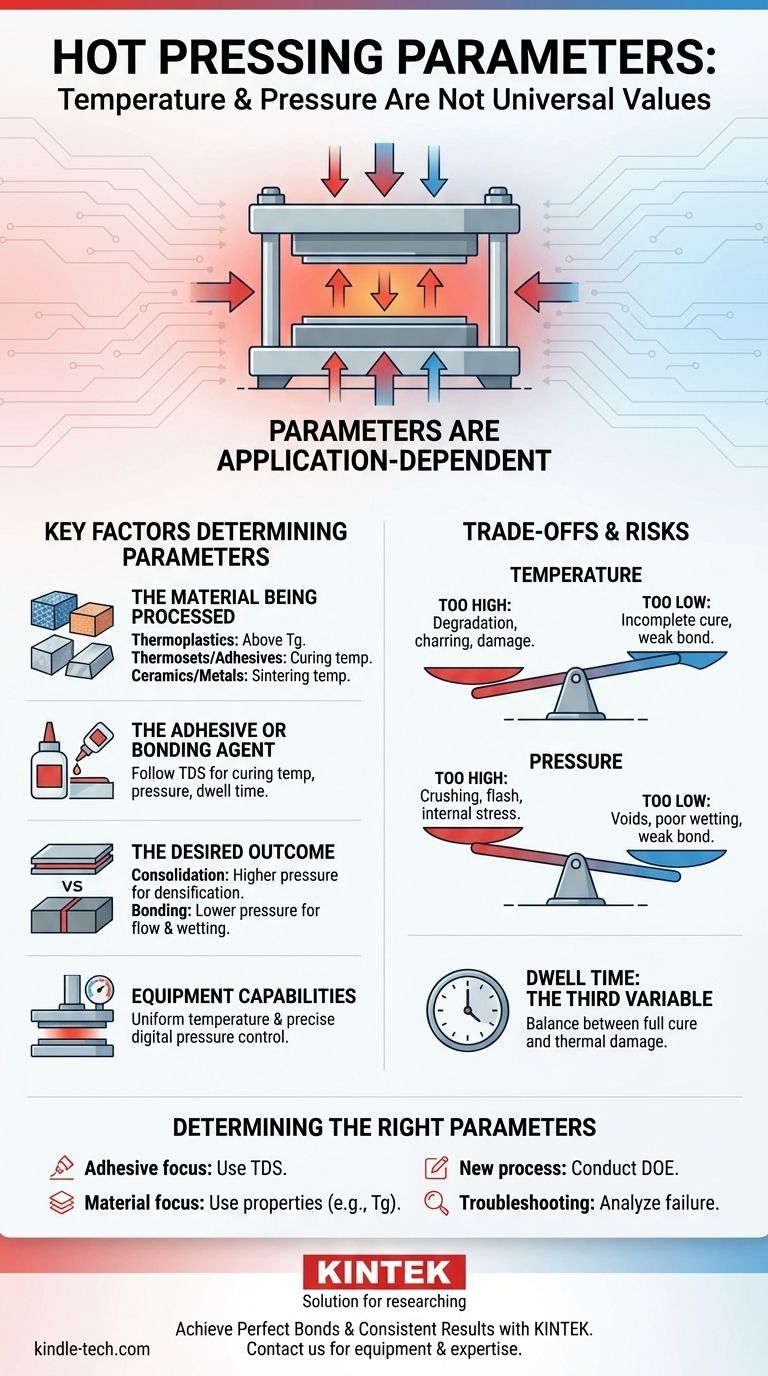

The exact temperature and pressure for hot pressing are not universal values; they are entirely dependent on the specific materials being processed and the desired outcome. The process parameters must be precisely tailored to the application, whether it involves bonding flexible circuits, laminating composites, or consolidating powdered materials.

Successful hot pressing is not achieved by using a single, predefined set of numbers. It is achieved by understanding the critical material properties and process goals, which then dictate the correct temperature, pressure, and time for your specific application.

Key Factors That Determine Hot Pressing Parameters

To define the correct process window, you must first analyze the fundamental characteristics of your materials and your end goal. The parameters are a direct function of these factors.

The Material Being Processed

The primary driver for temperature selection is the material itself. Different material types have vastly different thermal requirements.

For thermoplastics, the processing temperature is typically set above the material's glass transition temperature (Tg), where it becomes soft and pliable, but below its degradation temperature.

For thermosetting polymers or adhesives, the temperature must be sufficient to initiate and complete the chemical cross-linking (curing) reaction as specified by the manufacturer.

For ceramics or powdered metals, the goal is often densification through sintering. This requires very high temperatures and pressures to reduce porosity and form a solid mass.

The Adhesive or Bonding Agent

If you are using hot pressing to bond two components together with an adhesive film, the adhesive's properties will dictate your entire process.

The manufacturer's Technical Data Sheet (TDS) is your most critical document. It will specify the required temperature ramp rate, the precise curing temperature, the recommended pressure, and the necessary dwell time to achieve a full-strength bond.

The Desired Outcome

The "why" behind your process is crucial. Are you trying to fuse materials together or simply apply pressure while an adhesive cures?

Consolidation and densification (e.g., forming a composite panel) often require higher pressures to eliminate voids and ensure intimate contact between layers.

Adhesive bonding (e.g., attaching a flexible circuit to a display) may require lower pressure. The goal is only to ensure the adhesive flows and wets the surfaces evenly without damaging the delicate components.

Equipment Capabilities

The equipment itself plays a role. As noted, features like a titanium alloy head are designed for rapid and, most importantly, uniform temperature across the entire pressing surface.

Likewise, a system with a digital pressure gauge allows for precise and repeatable application of force. The ability of the machine to maintain even pressure is essential to prevent localized stress points and ensure a consistent bond.

Understanding the Trade-offs and Risks

Choosing parameters is a balancing act. Deviating from the optimal window introduces significant risks to your product quality.

Temperature: Too High vs. Too Low

Too high: Exceeding the material's thermal limit can cause irreversible degradation, charring, delamination, or damage to sensitive electronic components.

Too low: Insufficient heat will result in an incomplete cure for adhesives or inadequate softening for thermoplastics, leading to a weak or non-existent bond.

Pressure: Too High vs. Too Low

Too high: Excessive pressure can crush or damage delicate parts, cause the material or adhesive to "flash" (squeeze out from the sides), or create internal stress that leads to premature failure.

Too low: Insufficient pressure will prevent intimate contact between surfaces, leading to voids, poor adhesive wetting, and weak bond strength.

Dwell Time: The Third Critical Variable

Temperature and pressure are incomplete without time. The "dwell time" is how long the target temperature and pressure are maintained.

A short dwell time may not allow for a full adhesive cure or complete heat transfer through a thick part. An excessively long dwell time can lead to thermal damage and reduced manufacturing throughput.

How to Determine the Right Parameters for Your Application

There is no substitute for a methodical, data-driven approach to defining your hot pressing process.

- If your primary focus is bonding with an adhesive: Start with the adhesive's Technical Data Sheet (TDS). This is your ground truth for temperature, pressure, and time.

- If your primary focus is forming or consolidating a raw material: Begin with the material's documented properties, such as its glass transition temperature (Tg) or sintering temperature range.

- If you are developing a new process: Conduct a Design of Experiments (DOE) by creating a test matrix with slight variations in temperature, pressure, and time to identify the optimal window for your specific part geometry and materials.

- If you are troubleshooting a failed process: Analyze the failure mode. Delamination often points to issues with temperature or surface preparation, while damaged components suggest excessive pressure.

Ultimately, hot pressing is a precise thermal and mechanical process that must be dialed in for each unique task.

Summary Table:

| Key Factor | Why It Matters | How It Affects Parameters |

|---|---|---|

| Material Type | Different materials (plastics, ceramics, metals) have unique thermal properties. | Determines the required temperature range (e.g., above Tg for plastics). |

| Adhesive/Bonding Agent | Adhesives have specific curing requirements. | Temperature, pressure, and time are dictated by the adhesive's Technical Data Sheet (TDS). |

| Desired Outcome | The goal (e.g., bonding, consolidation, densification) varies. | Influences the required pressure level (high for densification, lower for delicate bonding). |

| Risks of Incorrect Settings | Using the wrong parameters can damage parts or create weak bonds. | Too High: Degradation, damage. Too Low: Weak bond, incomplete cure. |

Achieve Perfect Bonds and Consistent Results with KINTEK

Defining the precise hot pressing parameters for your specific materials and application is critical for success. KINTEK specializes in providing the lab equipment and expertise you need to master this process.

Our advanced hot presses, featuring uniform heating and precise digital pressure control, are designed to handle everything from delicate flexible circuits to robust composite materials. Let our team help you optimize your process for maximum bond strength and yield.

Contact us today using the form below to discuss your application, and we'll help you identify the ideal parameters and equipment for your laboratory's unique challenges.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Electric Heated Hydraulic Vacuum Heat Press for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What conditions does a Vacuum Hot Pressing Furnace provide for Copper-MoS2-Mo composites? Achieve Peak Densification

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- Why is a vacuum essential for sintering metal-ceramic composites? Achieve Pure, High-Density Results

- What are the advantages of using a vacuum hot press for CuCr50? Achieve Superior Density & Purity in Alloy Production

- Why is precise temperature control necessary for SiC/Cu Vacuum Hot Pressing? Mastering the Cu9Si Interface Phase