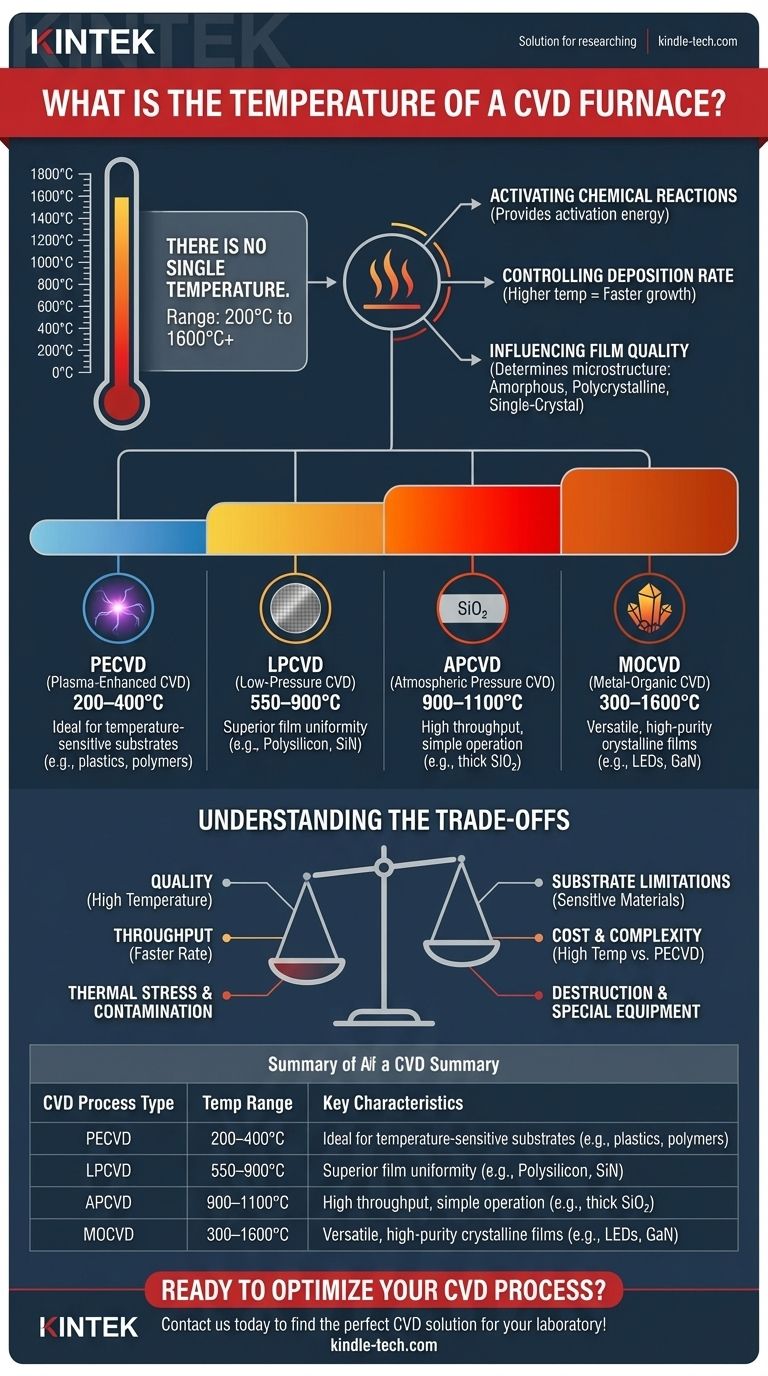

There is no single temperature for a Chemical Vapor Deposition (CVD) furnace. The required temperature is dictated entirely by the specific materials being deposited and the type of CVD process being used, with operational windows ranging from as low as 200°C to over 1600°C. Temperature is the primary control parameter that determines the chemical reaction, growth rate, and ultimate quality of the deposited film.

The temperature of a CVD furnace is not a fixed number but a critical variable that provides the necessary energy to initiate chemical reactions. Choosing the right temperature involves balancing the need for film quality, deposition speed, and the thermal limitations of the substrate material.

Why Temperature is the Driving Force in CVD

In any CVD process, precursor gases are introduced into a reaction chamber containing a substrate. For a solid film to form on that substrate, these gases must react. Temperature is the fundamental tool used to initiate and control these reactions.

Activating Chemical Reactions

Precursor molecules are generally stable at room temperature. Heat provides the activation energy needed to break chemical bonds within the precursor gases, allowing them to react with each other or decompose on the substrate surface. Without sufficient thermal energy, no deposition will occur.

Controlling Deposition Rate

Generally, a higher temperature leads to faster chemical reactions. This translates to a higher deposition rate, meaning the film grows thicker in less time. However, this relationship is not infinite; at very high temperatures, the process can become limited by how fast fresh gas can be supplied to the surface.

Influencing Film Quality

Temperature has a profound impact on the microstructure of the deposited film. It can be the deciding factor between depositing an amorphous (disordered), polycrystalline (many small crystal grains), or single-crystal (a perfect, continuous lattice) film. It also affects film density, stress, and purity.

The Wide Spectrum of CVD Temperatures

Different CVD techniques were developed specifically to operate in different temperature regimes, often to accommodate different materials or substrates.

Atmospheric Pressure CVD (APCVD)

Operating at atmospheric pressure, APCVD typically requires high temperatures (900–1100°C). It is a relatively simple, high-throughput method often used for depositing thick layers of silicon dioxide on silicon wafers in semiconductor manufacturing.

Low-Pressure CVD (LPCVD)

By reducing the chamber pressure, LPCVD processes can often run at slightly lower temperatures than APCVD while achieving superior film uniformity. Temperatures are still significant, for example, 550-650°C for polysilicon or around 900°C for silicon nitride.

Plasma-Enhanced CVD (PECVD)

PECVD is a game-changer for temperature-sensitive applications. Instead of relying solely on thermal energy, it uses an RF-generated plasma to break down precursor gases. This allows for deposition at much lower temperatures, typically 200–400°C, making it ideal for depositing films on plastics, polymers, or fully fabricated devices that cannot withstand high heat.

Metal-Organic CVD (MOCVD)

MOCVD is a highly versatile technique used to grow high-purity crystalline films, especially compound semiconductors for LEDs and high-frequency electronics. The temperature range is extremely wide (300–1600°C), depending entirely on the material system. Growing Gallium Nitride (GaN), for example, requires temperatures well above 1000°C.

Understanding the Trade-offs

Choosing a temperature is not just about meeting a minimum requirement; it's a strategic decision based on critical trade-offs.

Quality vs. Throughput

While higher temperatures often increase the deposition rate (throughput), they can also introduce unwanted side effects. Excessive heat can cause thermal stress in the film, leading to cracking, or cause diffusion of atoms from the substrate into the growing film, contaminating it.

Substrate Limitations

This is often the most significant constraint. You cannot run a 900°C LPCVD silicon nitride process on a plastic substrate, as it would be instantly destroyed. Similarly, depositing a final passivation layer on a microchip with aluminum wiring requires a low-temperature PECVD process to avoid melting the metal interconnects.

Cost and Complexity

High-temperature furnaces (above 1200°C) require specialized heating elements, chamber materials (like quartz or silicon carbide), and significant power consumption, making them more expensive to build and operate. PECVD systems, while operating at low temperatures, add the complexity and cost of RF plasma generation and matching networks.

Selecting the Right Temperature Window for Your Process

Your choice of a CVD process and its temperature is fundamentally linked to your end goal. The material you need and the substrate you have will dictate the required temperature window.

- If your primary focus is high-quality, single-crystal films for electronics or optics: You will likely need a high-temperature MOCVD or LPCVD process that provides enough energy for perfect atomic arrangement.

- If your primary focus is depositing on temperature-sensitive substrates like polymers or finished devices: A low-temperature PECVD process is your only viable option, as the plasma provides the energy that heat cannot.

- If your primary focus is high-volume, low-cost deposition of a simple material like silicon dioxide: A high-temperature APCVD or LPCVD process often provides the best balance of speed and cost-effectiveness.

Ultimately, temperature is the primary lever you pull to control the chemistry, structure, and properties of the material you create with CVD.

Summary Table:

| CVD Process Type | Typical Temperature Range | Key Characteristics |

|---|---|---|

| APCVD | 900–1100°C | High throughput, simple operation, used for thick SiO₂ layers |

| LPCVD | 550–900°C | Superior film uniformity, used for polysilicon and silicon nitride |

| PECVD | 200–400°C | Low-temperature process, ideal for temperature-sensitive substrates |

| MOCVD | 300–1600°C | Versatile, used for high-purity crystalline films like GaN for LEDs |

Ready to optimize your CVD process with the right furnace? KINTEK specializes in high-performance lab equipment, including CVD furnaces tailored for your specific material and substrate requirements. Whether you need high-temperature stability for semiconductor films or low-temperature PECVD capabilities for delicate substrates, our experts can help you achieve superior film quality and deposition efficiency. Contact us today to discuss your application and find the perfect CVD solution for your laboratory!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- 1400℃ Controlled Atmosphere Furnace with Nitrogen and Inert Atmosphere

- 1700℃ Controlled Atmosphere Furnace Nitrogen Inert Atmosphere Furnace

People Also Ask

- What are the advantages of industrial CVD for solid boriding? Superior Process Control and Material Integrity

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor