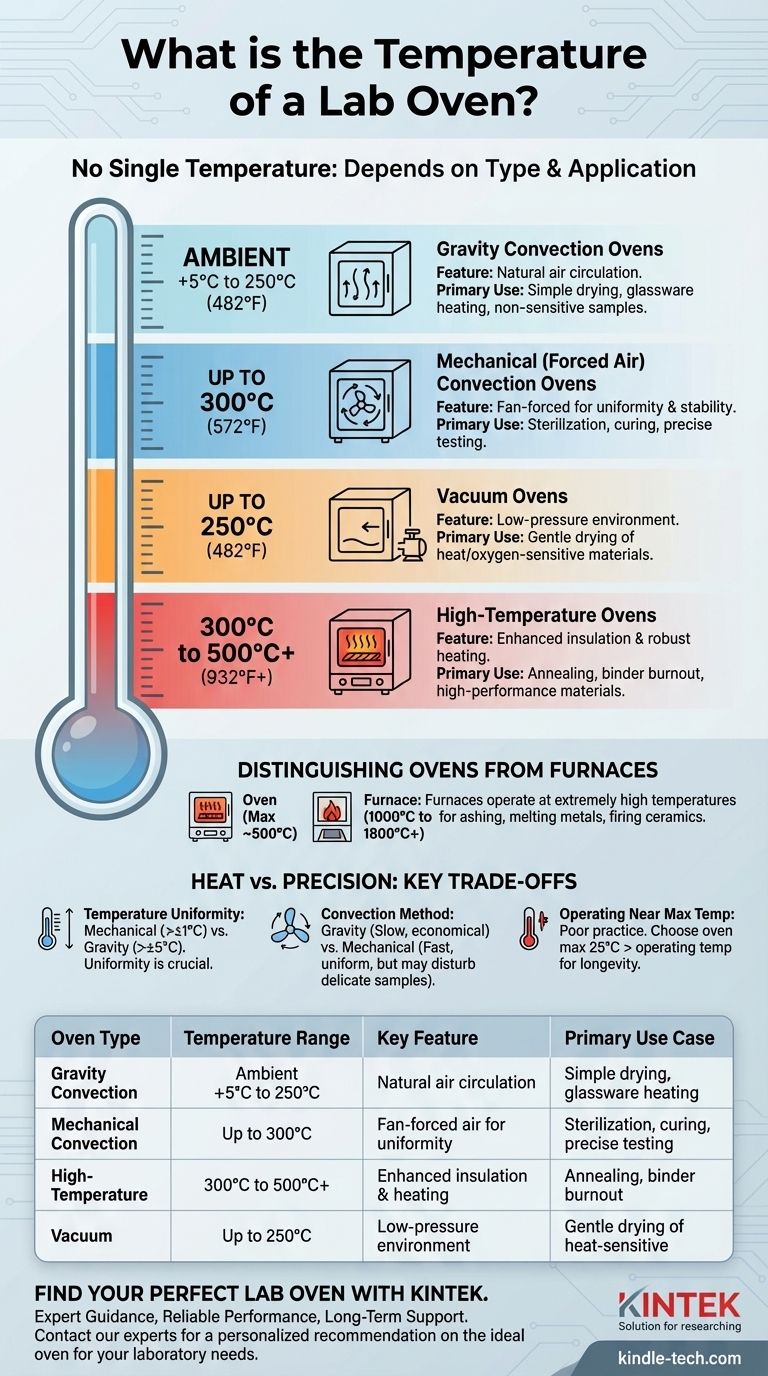

There is no single temperature for a lab oven. The operating temperature is entirely dependent on the oven's specific type and its intended application. A standard laboratory oven can typically range from just above ambient room temperature to around 300°C (572°F), but specialized models are designed for much higher or more controlled conditions.

The critical question is not "What is the temperature of a lab oven?" but rather "Which type of oven provides the specific temperature range, stability, and uniformity required for my scientific process?" Understanding the different classifications is key to selecting the right tool.

Classifying Ovens by Temperature and Function

The term "lab oven" is a broad category. Equipment is designed with different heating methods and temperature capabilities to serve distinct scientific needs, from simple drying to complex materials testing.

General Purpose & Gravity Convection Ovens

These are the most common and economical types of lab ovens. They rely on natural convection, where hot air rises and cooler air sinks to circulate heat.

Their typical temperature range is from ambient +5°C to 250°C (482°F). They are best suited for applications where precise temperature uniformity is not critical, such as drying glassware or performing simple heating processes.

Mechanical (Forced Air) Convection Ovens

These ovens use an internal fan to actively circulate hot air throughout the chamber. This mechanical convection results in far greater temperature uniformity and stability.

The temperature range is often similar to or slightly higher than gravity ovens, typically up to 300°C (572°F). They are the standard for applications requiring repeatable and precise thermal conditions, such as sterilization, component testing, and curing.

High-Temperature Ovens

For processes that exceed the limits of general-purpose ovens, high-temperature models are required. These feature enhanced insulation, more robust heating elements, and advanced controls.

Their operational range typically starts around 300°C and can exceed 500°C (932°F). They are used for demanding applications like annealing, binder burnout, or testing high-performance materials.

Vacuum Ovens

Vacuum ovens are highly specialized. Their primary feature is the ability to heat samples in a low-pressure environment, which allows moisture and solvents to be removed at a much lower temperature.

This prevents damage to heat-sensitive materials and eliminates oxidation during heating. While their temperature range can be up to 250°C (482°F), their main purpose is gentle, non-oxidative drying.

Distinguishing Ovens from Furnaces

It is crucial not to confuse a high-temperature oven with a laboratory furnace. Furnaces operate at extremely high temperatures, often from 1000°C to 1800°C (1832°F to 3272°F), and are used for processes like ashing, melting metals, and firing ceramics.

Understanding the Trade-offs: Heat vs. Precision

Choosing an oven involves balancing performance requirements with practical limitations. The highest temperature is not always the most important factor.

Temperature Range vs. Uniformity

An oven's maximum temperature rating is only part of the story. Temperature uniformity—the variation in temperature at different points within the chamber—is often more critical for reliable results.

A gravity convection oven may have hot and cold spots of ±5°C or more, while a high-quality mechanical convection oven can maintain uniformity of ±1°C.

The Impact of Convection Method

Gravity convection is simple and cost-effective, but the slow air movement can lead to long drying times and inconsistent heating.

Mechanical convection provides speed and uniformity but can be problematic for delicate samples. The airflow can disturb fine powders or dry out biological samples too quickly.

Operating Near Maximum Temperature

It is poor practice to continuously run an oven at its absolute maximum rated temperature. This puts significant strain on the heating elements and control systems, potentially reducing the equipment's lifespan and compromising its stability.

A good rule of thumb is to choose an oven with a maximum temperature at least 25°C higher than your regular operating temperature.

How to Select the Right Oven for Your Application

Now that you understand the different capabilities, you can select the correct tool based on your primary objective.

- If your primary focus is drying simple glassware or non-sensitive samples: A standard gravity convection oven (up to 250°C) is a cost-effective choice.

- If your primary focus is precise temperature control for testing, sterilization, or curing: A mechanical (forced air) convection oven (up to 300°C) is essential for its uniformity and stability.

- If your primary focus is drying heat-sensitive, hygroscopic, or oxygen-sensitive materials: A vacuum oven is the correct tool, as it allows for effective drying at lower temperatures.

- If your primary focus is high-heat material processing like annealing or ashing: You need a dedicated high-temperature oven (300°C+) or a laboratory furnace (1000°C+).

Choosing the right lab oven begins with clearly defining your process requirements, then selecting the equipment that meets those needs with precision and reliability.

Summary Table:

| Oven Type | Typical Temperature Range | Key Feature | Primary Use Case |

|---|---|---|---|

| Gravity Convection | Ambient +5°C to 250°C (482°F) | Natural air circulation | Simple drying, glassware heating |

| Mechanical Convection | Up to 300°C (572°F) | Fan-forced air for uniformity | Sterilization, curing, precise testing |

| High-Temperature | 300°C to 500°C+ (932°F+) | Enhanced insulation & heating | Annealing, binder burnout |

| Vacuum | Up to 250°C (482°F) | Low-pressure environment | Gentle drying of heat-sensitive materials |

Find Your Perfect Lab Oven with KINTEK

Selecting the right oven is critical for your lab's accuracy and efficiency. Whether you need a standard drying oven, a high-temperature model for materials testing, or a vacuum oven for sensitive samples, KINTEK has the solution.

We provide:

- Expert Guidance: Our specialists will help you match the oven type, temperature range, and convection method to your specific application.

- Reliable Performance: Our lab equipment ensures the temperature uniformity and stability your scientific processes demand.

- Long-Term Support: We are your partner in maintaining optimal lab performance.

Don't compromise on your results. Contact our experts today for a personalized recommendation on the ideal oven for your laboratory needs.

Visual Guide

Related Products

- Laboratory Scientific Electric Heating Blast Drying Oven

- 1200℃ Muffle Furnace Oven for Laboratory

- Automatic Laboratory Heat Press Machine

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

People Also Ask

- What is a lab oven used for? A Guide to Precise Heating, Sterilization & Drying

- What is a laboratory drying oven? The Essential Tool for Drying, Sterilizing, and Curing

- How does the oven work in the lab? A Guide to Precision Heating and Safety

- What is AC frame? Decoding the Two Meanings in Wi-Fi and Video

- What is a lab drying oven used for? Master Moisture Removal & Sterilization for Your Lab