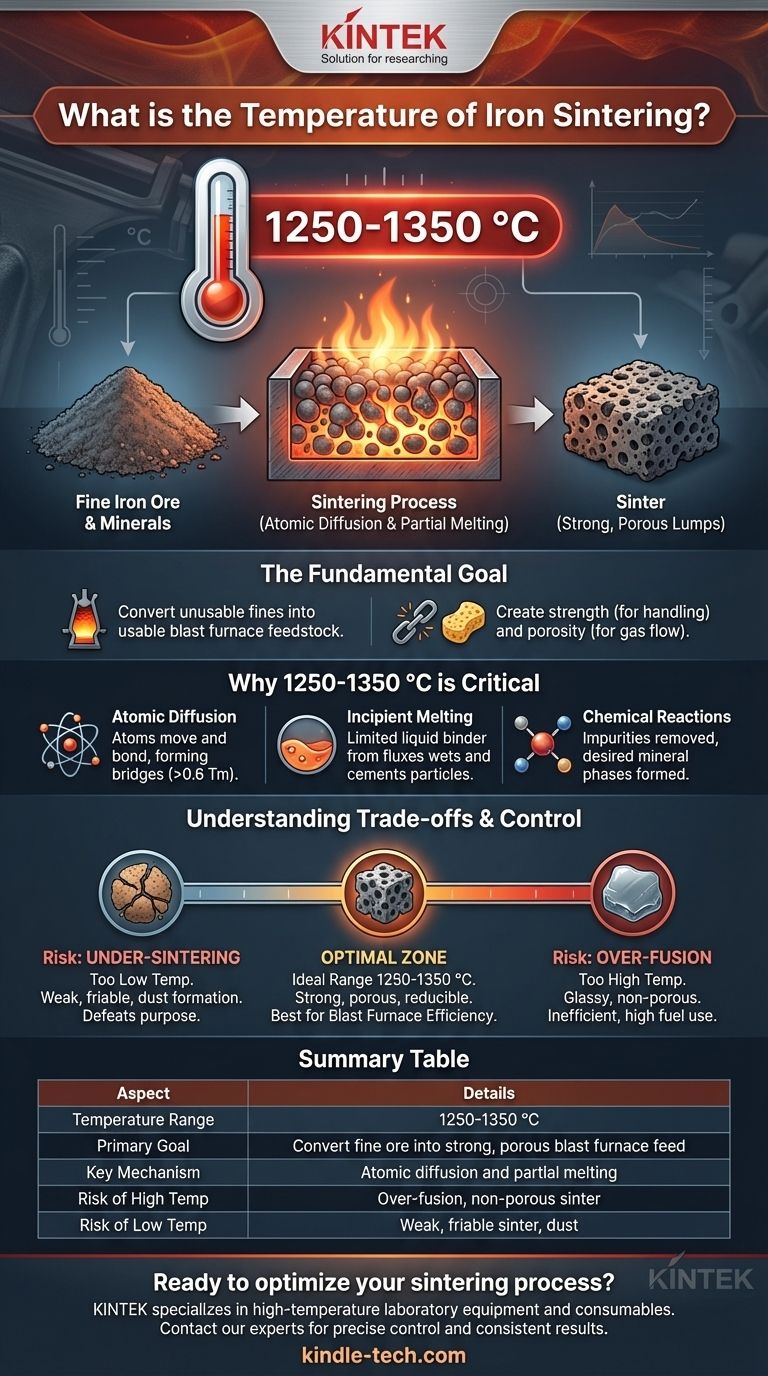

For the sintering of iron ore, the process is carried out at a temperature between 1250-1350 °C. At this critical temperature, the granulated mix of fine iron ores and other minerals is partially melted. This initiates a series of chemical reactions that bind the particles together, forming a solid, porous mass known as sinter.

The specific temperature for iron sintering is not arbitrary; it is a carefully controlled point below the full melting point of iron. This temperature is high enough to enable atomic diffusion and partial melting for binding, yet low enough to maintain the necessary porosity for its end use in a blast furnace.

The Fundamental Goal of Sintering Iron Ore

Sintering is a critical step in the steelmaking process. Its primary purpose is to convert unusable iron ore fines into a product with the right size, strength, and chemical properties for a blast furnace.

From Fine Particles to Usable Feedstock

Raw iron ore extracted from mines often consists of fine particles. If these were fed directly into a blast furnace, they would obstruct the flow of hot gases required for the reduction process. Sintering agglomerates these fines into larger, more uniform lumps.

Creating Strength and Porosity

The goal is to create a material that is mechanically strong enough to withstand handling and the weight of the material column inside the furnace. Simultaneously, the sinter must be porous to allow reducing gases to circulate efficiently and react with the iron oxides.

Why the 1250-1350 °C Range is Critical

The specific temperature window is a result of balancing multiple physical and chemical phenomena. It is directly related to the melting temperature of iron (approximately 1538 °C) and the behavior of the other materials in the mix.

The Principle of Atomic Diffusion

For particles to bond, atoms must be able to move and rearrange themselves at the contact points, reducing surface area and forming a solid bridge. This process, known as diffusion, requires significant thermal energy. Sintering temperatures are typically greater than 0.6 times the material's absolute melting temperature, a threshold that this range comfortably exceeds.

Incipient (Partial) Melting

This process does not fully melt the iron ore. Instead, it creates a limited amount of liquid phase from the fluxing agents (like limestone) and other low-melting-point compounds in the mix. This liquid acts as a binder, wetting the solid particles and solidifying upon cooling to cement them together.

Promoting Desired Chemical Reactions

The high temperature also drives essential chemical reactions. It helps remove volatile impurities and begins the formation of key mineral phases, like calcium ferrites, that give the final sinter its desirable strength and reducibility characteristics.

Understanding the Trade-offs and Process Control

Achieving optimal sinter quality requires strict control, as deviations from the target temperature can significantly degrade the final product.

The Risk of Over-Fusion

If the temperature is too high, excessive melting will occur. This can lead to the formation of a glassy, non-porous sinter. This material is difficult for gases to penetrate in the blast furnace, reducing efficiency and increasing fuel consumption.

The Problem of Under-Sintering

If the temperature is too low, diffusion and partial melting will be insufficient. The resulting sinter will be weak, friable, and prone to breaking down into dust during transport or inside the furnace, defeating the entire purpose of the process.

The Importance of Atmosphere

Sintering is conducted in a controlled atmosphere, often with forced air. This provides the oxygen necessary for the combustion of the fuel within the sinter mix (typically coke breeze) and helps control the oxidation state of the iron, which is critical for the final product's properties.

Making the Right Choice for Your Goal

The exact temperature and conditions are optimized based on the specific mineralogy of the ore and the desired properties of the final sinter.

- If your primary focus is maximizing blast furnace efficiency: You must ensure the sinter has high porosity and reducibility, which requires strict temperature control within the ideal 1250-1350 °C window to avoid over-fusion.

- If your primary focus is producing consistent, strong sinter: Concentrate on achieving a homogeneous mix and maintaining stable thermal conditions across the entire sinter bed to prevent weak, under-sintered zones.

- If your primary focus is fundamental material science: Remember that the temperature's function is to provide enough thermal energy (typically >0.6 Tm) to overcome activation barriers for atomic diffusion, which is the core mechanism of consolidation.

Ultimately, mastering sintering temperature is about balancing atomic mobility with structural integrity to create the ideal input for iron production.

Summary Table:

| Aspect | Details |

|---|---|

| Temperature Range | 1250-1350 °C |

| Primary Goal | Convert fine iron ore into strong, porous lumps for blast furnace feed |

| Key Mechanism | Atomic diffusion and partial melting to bind particles |

| Risk of High Temp | Over-fusion, creating non-porous, inefficient sinter |

| Risk of Low Temp | Weak, friable sinter that breaks down into dust |

Ready to optimize your sintering process? KINTEK specializes in high-temperature laboratory equipment and consumables for material testing and process development. Whether you are researching sintering parameters or scaling up production, our robust furnaces and expert support can help you achieve precise temperature control and consistent results. Contact our thermal processing experts today to discuss how we can support your laboratory and production goals in iron and steel manufacturing.

Visual Guide

Related Products

- Spark Plasma Sintering Furnace SPS Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What are the advantages of SPS? Achieve Superior Material Density and Performance

- What are the steps in spark plasma sintering? Achieve Rapid, Low-Temperature Densification

- What is the SPS process of spark plasma sintering? A Guide to Rapid, Low-Temperature Densification

- What is the plasma sintering technique? Achieve Rapid, High-Density Material Fabrication

- What are the different sintering methods? Choose the Right Technique for Your Material & Application