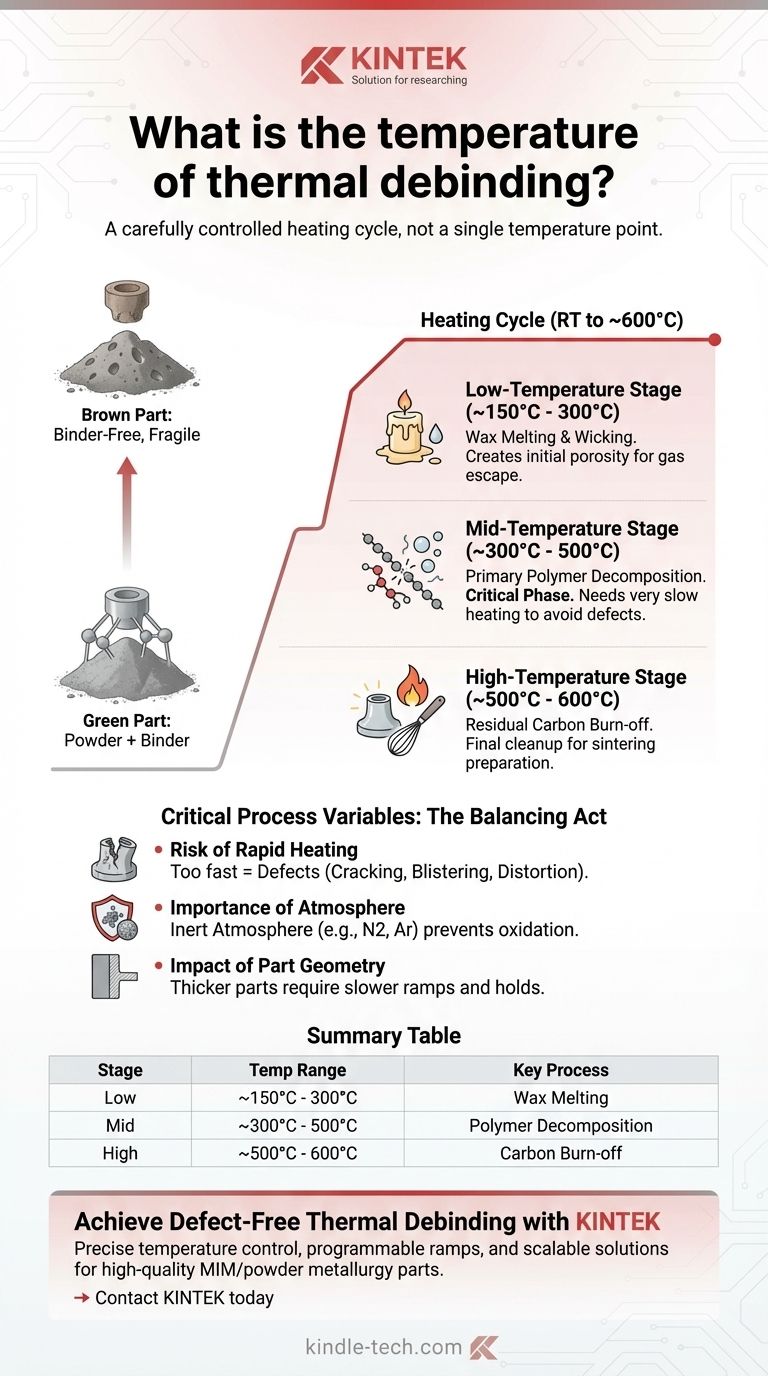

In thermal debinding, the process is not set to a single temperature but involves a carefully controlled heating cycle that typically ranges from room temperature up to approximately 600°C (1112°F). This multi-stage process is designed to systematically remove the polymer binder from the "green" part without introducing defects before the final sintering stage.

The core challenge of thermal debinding is not simply reaching a target temperature, but managing the rate of heating through different temperature zones. A slow, controlled ramp is essential to allow binder decomposition gases to escape without building up internal pressure that can crack or distort the fragile part.

The Purpose of Thermal Debinding

Thermal debinding is a critical step in powder metallurgy processes like Metal Injection Molding (MIM). It serves one primary function: to remove the "binder," which is a mixture of polymers and waxes that acts as a temporary glue.

This binder gives the component its shape and handling strength in its initial, unsintered state, often called the "green" part. Before the metal particles can be fused together in the high-temperature sintering furnace, this binder must be completely and cleanly eliminated.

The Stages of Binder Burnout

The process is a journey through distinct temperature zones, with each stage targeting a different component of the binder system. The final temperature profile depends heavily on the specific binder used and the part's geometry.

Low-Temperature Stage (~150°C - 300°C)

In this initial phase, the lowest-melting-point components of the binder, often waxes, begin to melt and wick to the surface or vaporize.

This is a crucial step because it opens up a network of pores within the part. This porosity acts as an escape route for the gases that will be generated in the next, more aggressive stage.

Mid-Temperature Stage (~300°C - 500°C)

This is the most critical and highest-risk phase of debinding. During this stage, the primary structural polymer of the binder system undergoes thermal decomposition, breaking down into gaseous byproducts.

The heating rate must be extremely slow here. If the temperature rises too quickly, the rate of gas generation will exceed the rate at which it can escape through the pore network, leading to part failure.

High-Temperature Stage (~500°C - 600°C)

This final stage acts as a cleanup phase. The furnace is held at this higher temperature to ensure any residual carbon left behind by the decomposed polymer is fully burned off.

Completing this stage is vital for achieving good material properties and preventing contamination in the subsequent sintering process. After this, the component is known as a "brown" part—extremely fragile but free of binder.

Understanding the Trade-offs: Critical Process Variables

Achieving a successful debind is a balancing act. Simply setting the furnace to 600°C will result in catastrophic failure. You must manage the entire cycle.

The Risk of Rapid Heating

The single most common cause of defects is a heating rate that is too fast. This traps decomposition gases, leading to a build-up of internal pressure that can cause:

- Cracking: The part literally fractures under pressure.

- Blistering: Pockets of gas form bubbles on the part's surface.

- Distortion: The part slumps or warps out of its intended shape.

The Importance of Atmosphere

Thermal debinding is rarely performed in ambient air, as this would oxidize the fine metal powders. The process is typically conducted in an inert atmosphere (like nitrogen or argon) or a vacuum.

This controlled atmosphere helps carry away the binder byproducts and, most importantly, protects the metal particles from oxidation until they are ready for sintering.

The Impact of Part Geometry

Thick or large parts are significantly more challenging to debind than thin-walled parts. It takes much longer for heat to penetrate to the core of a thick section.

Furthermore, the escape path for the decomposition gases is much longer. For this reason, thicker parts demand much slower heating ramps and may require extended "holds" at specific temperatures to allow the process to reach equilibrium.

Making the Right Choice for Your Process

The ideal thermal debinding cycle is specific to your binder, material, and part geometry. However, general principles can guide your approach.

- If your primary focus is part integrity: Prioritize a slow, conservative heating rate, especially between 300°C and 500°C where the bulk of the binder decomposes.

- If your primary focus is processing thick-sectioned parts: Implement an even slower heating profile and consider adding isothermal holds below and during the main decomposition stage to ensure uniform burnout from the core to the surface.

- If your primary focus is process optimization and speed: First establish a reliable, defect-free baseline cycle, then cautiously increase ramp rates in small increments, validating part quality at each step.

Ultimately, successful thermal debinding is achieved through patience and precise control, not just by reaching a final temperature.

Summary Table:

| Stage | Temperature Range | Key Process | Critical Factor |

|---|---|---|---|

| Low-Temperature | ~150°C - 300°C | Melting/evaporation of low-melting-point waxes | Creates initial porosity for gas escape |

| Mid-Temperature | ~300°C - 500°C | Decomposition of primary polymer binder | Slow heating rate is critical to avoid defects |

| High-Temperature | ~500°C - 600°C | Burn-off of residual carbon | Ensures clean part for sintering |

Achieve Defect-Free Thermal Debinding with KINTEK

Navigating the precise temperature cycles and heating rates of thermal debinding is critical for producing high-quality metal injection molded (MIM) or powder metallurgy parts. KINTEK specializes in laboratory furnaces and thermal processing solutions designed for the exacting control required in debinding and sintering.

Our expertise and equipment help you:

- Prevent Defects: Precise temperature control and programmable ramps minimize the risk of cracking, blistering, and distortion.

- Process Challenging Geometries: Optimize cycles for thick-sectioned or complex parts with reliable, uniform heating.

- Scale Your Process: From R&D to production, find the right furnace solution for your throughput and quality needs.

Ready to optimize your debinding process? Let our experts help you select the ideal thermal processing equipment. Contact KINTEK today to discuss your laboratory's specific requirements.

Visual Guide

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Spark Plasma Sintering Furnace SPS Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is the use of a digital muffle furnace? Achieve Contamination-Free High-Temperature Processing

- What is the annealing temperature of quartz? Achieve Optimal Thermal Stability for Your Components

- What is the purpose of a laboratory furnace? Achieve Precise High-Temperature Processing

- What is the thermal debinding process? A Guide to Safe Binder Removal for MIM & Ceramics

- What is the difference between a lab oven and a furnace? Choose the Right Tool for Your Thermal Process