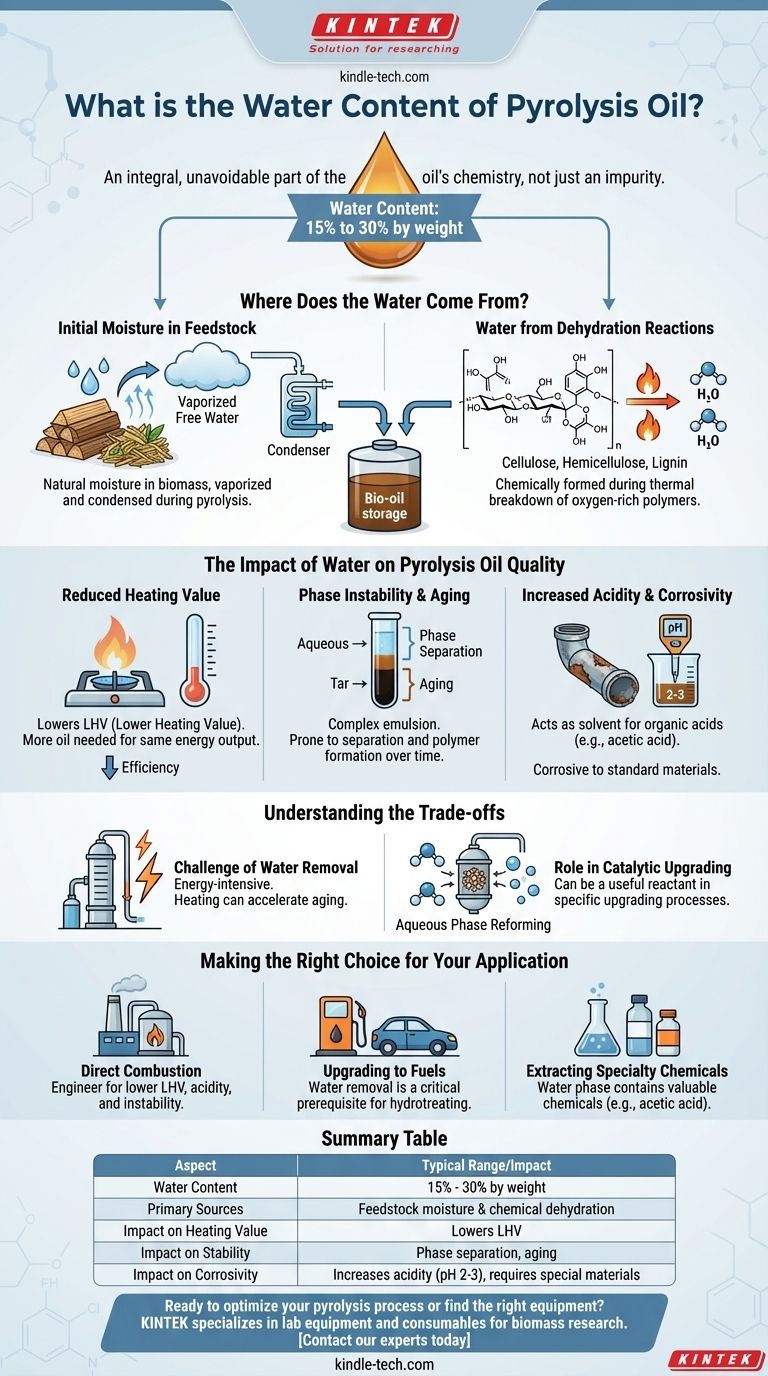

The water content of pyrolysis oil typically ranges from 15% to 30% by weight. This significant water component is not merely an impurity but an integral part of the oil's formation and complex chemistry. The water originates from both the initial moisture present in the biomass feedstock and as a direct product of the chemical dehydration reactions that occur during the pyrolysis process itself.

The presence of water in pyrolysis oil is an unavoidable consequence of its production, fundamentally defining its properties. Rather than viewing it as a simple contaminant, it is critical to understand its origins and impact on the oil's energy content, stability, and potential for upgrading into higher-value products.

Where Does the Water Come From?

The water found in pyrolysis oil, also known as bio-oil, has two primary sources. Understanding both is key to managing the final product's quality.

Initial Moisture in the Feedstock

Biomass, such as wood chips, agricultural residues, or energy crops, naturally contains water. Even after drying, a residual amount of moisture remains.

During pyrolysis, this "free water" is vaporized at high temperatures and is then condensed along with the organic vapors, becoming part of the final liquid bio-oil.

Water from Dehydration Reactions

This is the "reaction water" and is chemically formed during the process. Biomass is made of cellulose, hemicellulose, and lignin—large polymers rich in oxygen.

As these complex structures are thermally broken down, their chemical bonds rearrange, splitting off water (H₂O) molecules from the organic framework. These dehydration reactions are a fundamental part of pyrolysis chemistry and are a major reason why bio-oil has such a high oxygen content.

The Impact of Water on Pyrolysis Oil Quality

The high water content presents several significant challenges for the storage, transport, and utilization of pyrolysis oil.

Reduced Heating Value

Water does not combust and adds inert mass to the fuel. A higher water content directly lowers the Lower Heating Value (LHV) of the bio-oil.

This means more oil is required to produce the same amount of energy compared to a conventional fossil fuel, impacting its efficiency for direct combustion in boilers or engines.

Phase Instability and Aging

Pyrolysis oil is not a true solution but a complex emulsion or micro-emulsion of water and hundreds of different organic compounds.

Over time, or with changes in temperature, this oil is prone to aging. The compounds can continue to react, forming larger polymers and causing the oil to separate into an aqueous phase and a viscous, tar-like organic phase. This makes it difficult to pump, atomize, and burn effectively.

Increased Acidity and Corrosivity

The water in bio-oil acts as a solvent for organic acids, such as the acetic acid and formic acid mentioned in the reference materials, which are also formed during pyrolysis.

This makes the oil highly acidic (with a pH typically between 2 and 3), rendering it corrosive to common construction materials like carbon steel. Storage tanks, pumps, and fuel lines require more expensive stainless steel or other resistant materials.

Understanding the Trade-offs

Managing the water content of pyrolysis oil is a central challenge in making it a viable mainstream energy source.

The Challenge of Water Removal

Simply separating the water is not straightforward. Because many of the organic compounds are polar and have some solubility in water, it's not a simple oil-water separation.

Energy-intensive processes like distillation are required, but heating the bio-oil can accelerate the undesirable aging reactions, further degrading its quality. This creates a difficult technical and economic problem to solve.

Water's Role in Catalytic Upgrading

Paradoxically, in some advanced upgrading processes, water can be a useful component. In techniques like aqueous phase reforming (APR), water itself acts as a reactant.

These processes are designed to work with wet feedstocks to produce hydrogen or other more stable chemical intermediates. Here, the presence of water is not a flaw but a feature to be leveraged.

Making the Right Choice for Your Application

Your strategy for dealing with water in pyrolysis oil depends entirely on your end goal.

- If your primary focus is direct combustion for heat or power: You must engineer your system to handle a fuel with a lower heating value, high acidity, and potential instability.

- If your primary focus is upgrading to transportation fuels: Water removal is a critical and energy-intensive prerequisite. The goal of processes like hydrotreating is to remove oxygen, which includes breaking down the water.

- If your primary focus is extracting specialty chemicals: The water phase itself can be a valuable source of water-soluble chemicals like acetic acid, while the organic phase contains valuable phenols and other compounds.

Understanding and managing the inherent water content is the key to unlocking the full potential of pyrolysis oil as a renewable resource.

Summary Table:

| Aspect | Typical Range/Impact |

|---|---|

| Water Content | 15% - 30% by weight |

| Primary Sources | Feedstock moisture & chemical dehydration reactions |

| Key Impact on Heating Value | Lowers Lower Heating Value (LHV) |

| Key Impact on Stability | Causes phase separation and aging over time |

| Key Impact on Corrosivity | Increases acidity (pH 2-3), requiring special materials |

Ready to optimize your pyrolysis process or find the right equipment to handle bio-oil's unique challenges?

KINTEK specializes in lab equipment and consumables for advanced biomass research and analysis. Whether you are developing new upgrading techniques, testing feedstock, or analyzing fuel properties, we provide the reliable tools you need.

Contact our experts today to discuss how our solutions can support your renewable energy projects.

Visual Guide

Related Products

- Filter Testing Machine FPV for Dispersion Properties of Polymers and Pigments

- Automatic Laboratory Heat Press Machine

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- Electrolytic Electrochemical Cell for Coating Evaluation

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

People Also Ask

- What is the working principle of rotor furnace? Achieving Perfect Heat Treatment Uniformity

- What are the limitations of flash pyrolysis? Key Challenges in Bio-Oil Production

- How efficient is pyrolysis? A Strategic Guide to Maximizing Output

- What are the materials suitable for pyrolysis? Unlocking Value from Waste Streams

- What are the gaseous products of pyrolysis? Understanding Syngas for a Self-Sustaining Process

- What are disadvantages of plastic pyrolysis? Key Challenges and Environmental Trade-offs

- How do you choose calcination temperature? A Guide to Optimizing Material Properties

- What is the temperature range for calcination? Master the 800°C to 1300°C Process