The primary machine used to make molded parts is an injection molding machine. This powerful equipment functions by injecting molten material, most commonly plastic, under high pressure into a precisely machined mold, or tool. Once the material cools and solidifies, the machine opens the mold and ejects a finished, perfectly formed part.

While several types of molding exist, the injection molding machine is the cornerstone of modern mass production. It transforms raw plastic pellets into finished parts with incredible speed and repeatability, but its effectiveness is entirely dependent on the quality of the custom-made mold it uses.

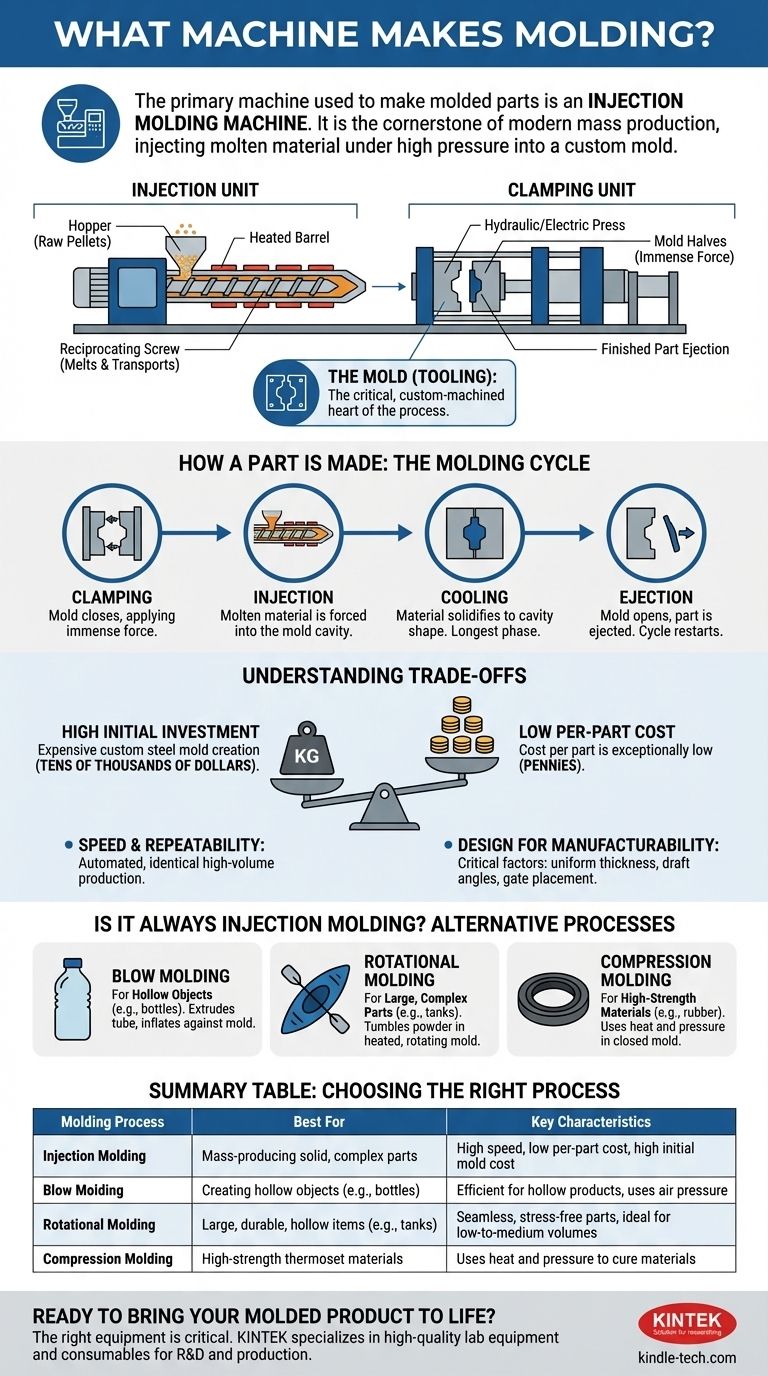

The Anatomy of an Injection Molding Machine

An injection molding machine is not a single device but a system of two core units working in perfect synchronization: the injection unit and the clamping unit.

The Injection Unit: From Pellet to Liquid

This is where the raw material begins its transformation. It consists of a hopper, which feeds plastic pellets into a heated barrel. Inside the barrel, a large reciprocating screw both transports and melts the plastic, preparing a precise "shot" of molten material for injection.

The Clamping Unit: The Source of Immense Force

The clamping unit acts like a powerful hydraulic or electric press. Its job is to hold the two halves of the steel mold shut with immense force, measured in tons. This force is necessary to resist the high pressure of the injected molten plastic, preventing it from leaking out and ensuring the part is formed correctly.

The Mold (Tooling): The Heart of the Process

The mold, also called the tool or die, is the most critical component. It is a custom-machined block of steel with a cavity cut into it that is the negative image of the part you want to create. The quality, precision, and design of the mold dictate the final quality of the product.

How a Part is Made: The Molding Cycle Explained

The process of creating a single part is a rapid, four-stage cycle that often takes only seconds to complete.

Step 1: Clamping

The clamping unit pushes the two halves of the mold together and applies thousands of pounds of force to keep it securely closed.

Step 2: Injection

The injection unit's screw drives forward, forcing the prepared shot of molten plastic from the barrel into the mold's cavity at high pressure.

Step 3: Cooling

The molten plastic inside the mold begins to cool, often aided by internal water channels. As it cools, it solidifies into the shape of the cavity. This is typically the longest phase of the cycle.

Step 4: Ejection

Once the part is sufficiently solid, the clamping unit opens the mold. Ejector pins then push the finished part out of the mold, and the cycle begins again.

Understanding the Trade-offs of Injection Molding

While incredibly effective, this process involves critical considerations that determine its suitability for a project.

High Initial Investment vs. Low Per-Part Cost

The primary trade-off is cost. The custom steel mold is extremely expensive to design and manufacture, often costing tens of thousands of dollars. However, once the mold is made, the cost to produce each individual part is exceptionally low, often just pennies.

Speed and Repeatability

Injection molding is one of the fastest manufacturing processes. Its automated nature ensures that every part produced, from the first to the millionth, is virtually identical. This makes it the undisputed standard for high-volume production.

Design for Manufacturability is Critical

Parts must be designed specifically for the injection molding process. Factors like uniform wall thickness, draft angles (slight tapers to help with ejection), and the placement of gates (where plastic enters the mold) are non-negotiable for success.

Is It Always an Injection Molding Machine?

While injection molding is the most common, other specialized machines create different types of molded products.

Blow Molding: For Hollow Objects

This process is used to make hollow parts like bottles and containers. It works by extruding a tube of molten plastic (a "parison") and then using air pressure to inflate it against the walls of a mold.

Rotational Molding: For Large, Complex Parts

Also known as rotomolding, this method is ideal for creating large, seamless, and stress-free hollow parts like kayaks, water tanks, and playground equipment. It involves tumbling plastic powder inside a heated, rotating mold.

Compression Molding: For High-Strength Materials

This technique is often used with thermoset materials like rubber or silicone. A pre-measured amount of material is placed directly into a heated mold cavity, which is then closed, applying heat and pressure to cure the material into its final shape.

Choosing the Right Molding Process

Your final product's geometry, material, and required production volume will dictate the correct machine and process.

- If your primary focus is mass-producing solid, complex parts: The injection molding machine is the industry standard for its speed and low per-part cost.

- If your primary focus is creating hollow products like bottles: Blow molding is the specialized, highly efficient process you need.

- If your primary focus is large, durable, hollow items: Rotational molding offers design freedom and strength for low-to-medium volume production.

- If your primary focus is strong, heat-resistant parts from thermoset materials: Compression molding is the ideal method.

Understanding the machine and its corresponding process is the first step toward bringing a physical product to life at scale.

Summary Table:

| Molding Process | Best For | Key Characteristics |

|---|---|---|

| Injection Molding | Mass-producing solid, complex parts | High speed, low per-part cost, high initial mold cost |

| Blow Molding | Creating hollow objects (e.g., bottles) | Efficient for hollow products, uses air pressure |

| Rotational Molding | Large, durable, hollow items (e.g., tanks) | Seamless, stress-free parts, ideal for low-to-medium volumes |

| Compression Molding | High-strength thermoset materials (e.g., rubber) | Uses heat and pressure to cure materials |

Ready to bring your molded product to life? The right equipment is critical for success. At KINTEK, we specialize in providing high-quality lab equipment and consumables to support your R&D and production needs. Whether you're prototyping a new design or scaling up for mass production, our experts can help you find the perfect solution. Contact our team today to discuss how we can support your laboratory and manufacturing goals!

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- Anti-Cracking Press Mold for Lab Use

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- What is twin screw granulation? A Guide to Modern, Continuous Pharmaceutical Manufacturing

- Why is calendering important? Achieve Superior Fabric Finishing for Your Textiles

- What are the advantages of a two-high rolling mill? Cost-Effective Durability for Heavy Reduction

- What is a two-high roll mill? Master Precise Material Compounding and Testing

- What is a 3 hi rolling mill? A Guide to Efficient Bidirectional Metal Shaping

- How many types of mixers are there? Find the Right Mixing Mechanism for Your Material

- What is the difference between calendaring and calendering? Master the Key Spelling and Context

- How profitable is injection molding? Unlock High-Volume Manufacturing Profitability