The single most important maintenance check for the electrical connections of an electrode holder is to periodically inspect the wire connections. You must ensure they are physically secure and free of any corrosion or residue to guarantee good electrical conductivity.

A loose or dirty electrical connection is not a minor inconvenience; it is a critical failure point. Proper maintenance extends beyond the wires to encompass the entire electrical path, ensuring the integrity of your results and the safety of your equipment.

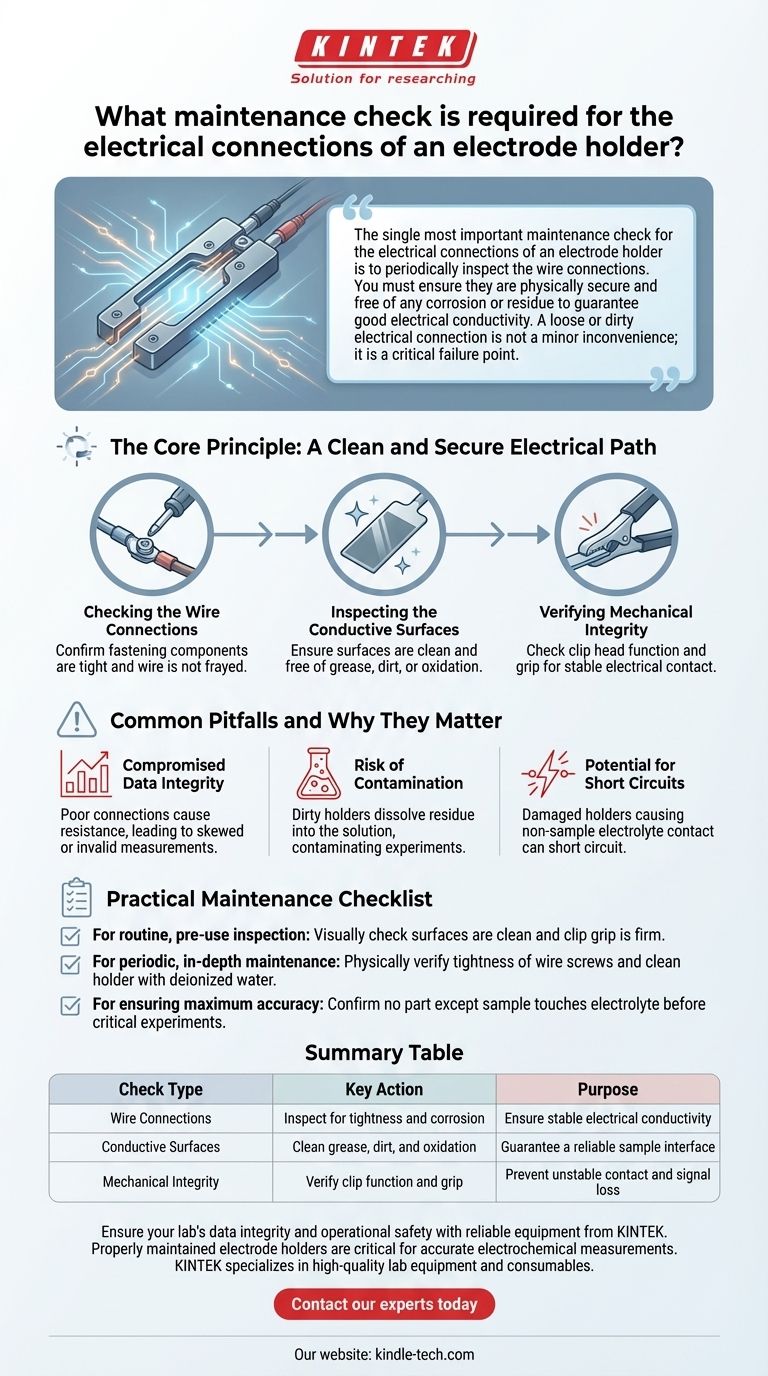

The Core Principle: A Clean and Secure Electrical Path

The primary goal of any electrode holder is to create a stable and reliable electrical circuit between your instrument and the sample. Any interruption or inconsistency in this path directly compromises your work.

Checking the Wire Connections

The most direct point of failure is where the wires physically connect to the holder.

Your check should confirm two things: that all fastening components, like screws, are tight and that there is no fraying or damage to the wire itself. A loose connection introduces resistance and can lead to inaccurate readings or a complete loss of signal.

Inspecting the Conductive Surfaces

The electrical path doesn't end at the wire terminal. It extends to the surface that makes contact with your sample.

The conductive sheet or clip must be clean and free of grease, dirt, or oxidation. These impurities act as insulators, impeding the flow of current and creating an unreliable interface with the sample.

Verifying Mechanical Integrity

The mechanical function of the holder is directly tied to its electrical performance.

A clip head that does not open and close correctly or fails to grip the sample firmly will create an unstable electrical contact. This can cause fluctuating readings or intermittent signal loss during an experiment.

Common Pitfalls and Why They Matter

Neglecting these simple checks can have significant consequences that undermine the purpose of your work. Understanding the risks reinforces the importance of a consistent maintenance routine.

Compromised Data Integrity

A poor connection creates unwanted electrical resistance. This can alter your measurements, leading to skewed, unreliable, or completely invalid data. The results will not accurately reflect the properties of your sample.

Risk of Contamination

Proper procedure dictates that only the test sample should touch the electrolyte. If the holder is dirty, residue can dissolve into the solution, contaminating the experiment.

Potential for Short Circuits

If a damaged holder allows any part other than the sample—such as the clip or fasteners—to make contact with the electrolyte, it can cause a short circuit. This will instantly invalidate the experiment and could potentially damage your instrumentation.

A Practical Maintenance Checklist

To ensure reliable performance, integrate these checks into your workflow based on your specific needs.

- For routine, pre-use inspection: Visually check that the conductive surfaces are clean and ensure the clip mechanism provides a firm, secure grip on the sample.

- For periodic, in-depth maintenance: Physically verify that all wire connection screws are tight and thoroughly clean the holder with deionized water, allowing it to dry completely.

- For ensuring maximum accuracy: Before a critical experiment, perform all checks and confirm that no part of the holder except the sample can possibly contact the electrolyte solution.

Ultimately, consistent and thorough maintenance is the foundation of repeatable and trustworthy results.

Summary Table:

| Check Type | Key Action | Purpose |

|---|---|---|

| Wire Connections | Inspect for tightness and corrosion | Ensure stable electrical conductivity |

| Conductive Surfaces | Clean grease, dirt, and oxidation | Guarantee a reliable sample interface |

| Mechanical Integrity | Verify clip function and grip | Prevent unstable contact and signal loss |

Ensure your lab's data integrity and operational safety with reliable equipment from KINTEK.

Properly maintained electrode holders are critical for accurate electrochemical measurements. KINTEK specializes in high-quality lab equipment and consumables, providing the reliable tools your laboratory needs to achieve precise and repeatable results.

Don't let faulty connections compromise your research. Contact our experts today to find the right electrode holders and maintenance solutions for your specific application.

Visual Guide

Related Products

- Custom PTFE Wafer Holders for Lab and Semiconductor Processing

- Vertical Laboratory Tube Furnace

- Variable Speed Peristaltic Pump

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What are the recommended and prohibited cleaning methods for the PTFE electrode stand? Protect Your Lab Equipment

- What materials are the sample holders made of? Engineered with PTFE and PEEK for Purity

- What is the correct way to place items into a PTFE cleaning basket? Master the Art of Perfect, Repeatable Cleaning

- How should a PTFE cleaning basket be stored when not in use? Maximize Lifespan & Prevent Contamination

- Why is it necessary to utilize PTFE sample holders in electroless nickel plating? Ensure Process Integrity