There is no single 'best' material for a crucible. The optimal choice is entirely dependent on the specific application, as the material must be chemically compatible with the substance being heated and able to withstand the required process temperatures without failing or contaminating the melt.

The core task is not to find one universally superior material, but to match the crucible’s properties—primarily its temperature resistance and chemical inertness—to the unique demands of the substance you are working with.

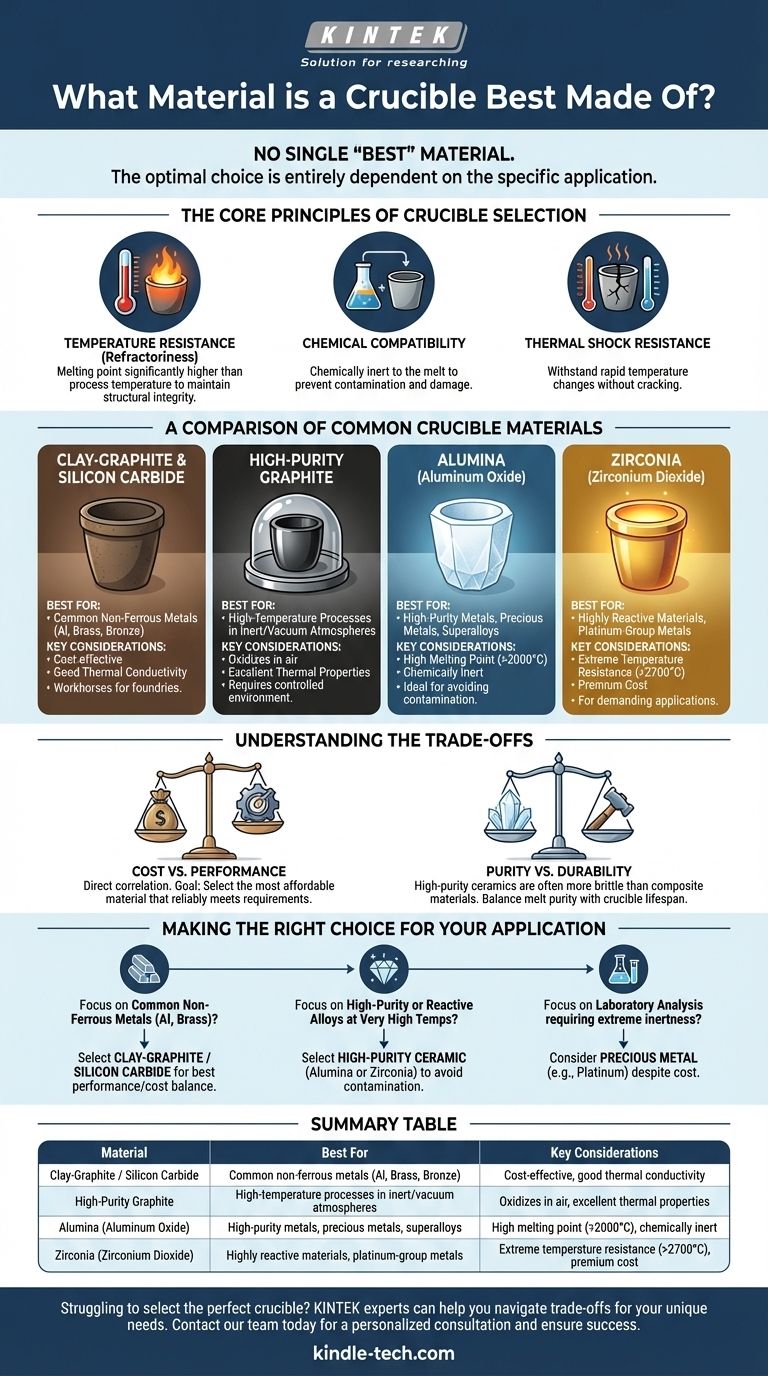

The Core Principles of Crucible Selection

To choose the right material, you must evaluate it against a few fundamental requirements. A failure in any one of these areas can lead to a ruined product, a destroyed crucible, and a potential safety hazard.

Temperature Resistance (Refractoriness)

The most basic requirement is that the crucible must have a melting point significantly higher than the operating temperature of your process. This property is known as refractoriness.

This ensures the crucible maintains its structural integrity and does not deform or fail when holding the molten material.

Chemical Compatibility

A crucible must be chemically inert with respect to the material it holds. It cannot react with, dissolve in, or otherwise contaminate the molten substance, which is often called the "melt."

This is critical for achieving high-purity final products in metallurgy and for accurate results in laboratory settings. An incompatible crucible will not only ruin the melt but will also be damaged or destroyed in the process.

Thermal Shock Resistance

Materials expand when heated and contract when cooled. A crucible must be able to withstand these rapid temperature changes without cracking.

This property, known as thermal shock resistance, is crucial for applications where crucibles are moved in and out of a furnace or where temperatures fluctuate quickly.

A Comparison of Common Crucible Materials

Different materials excel under different conditions. Understanding the strengths and weaknesses of the most common options is key to making an informed decision.

Clay-Graphite and Silicon Carbide

These composite materials are the workhorses for many foundries. The graphite provides excellent thermal conductivity for efficient melting, while the clay or silicon carbide binder adds strength and durability.

They are an excellent, cost-effective choice for melting common non-ferrous metals like aluminum, brass, and bronze.

High-Purity Graphite

Crucibles made of pure graphite have outstanding thermal properties. However, their primary limitation is that graphite oxidizes (burns away) in the presence of oxygen at high temperatures.

For this reason, they are typically used in vacuum or inert-atmosphere furnaces to prevent degradation.

Alumina (Aluminum Oxide)

Alumina is a hard, dense ceramic with a very high melting point (above 2000°C). It is highly resistant to chemical attack from many molten metals and slags.

This makes it an ideal choice for melting high-purity metals, precious metals, or superalloys where contamination from a carbon-based crucible (like graphite) is unacceptable.

Zirconia (Zirconium Dioxide)

For applications requiring even higher temperatures than alumina can handle, zirconia is the premium choice. It boasts exceptional refractoriness, with a melting point over 2700°C.

Zirconia is used for melting highly reactive materials, platinum-group metals, and specialty refractory metals that would destroy lesser materials.

Understanding the Trade-offs

Choosing a crucible material is an exercise in balancing competing factors. What you gain in one area, you often sacrifice in another.

Cost vs. Performance

There is a direct and steep correlation between performance and price. A clay-graphite crucible may cost tens or hundreds of dollars, while a high-purity zirconia crucible of the same size can cost thousands.

The goal is to select the most affordable material that reliably meets all the technical requirements of your specific process. Over-specifying is a waste of resources.

Purity vs. Durability

High-purity ceramics like alumina and zirconia offer superior chemical inertness but are often more brittle and susceptible to thermal shock than composite materials like silicon carbide.

There can be a direct trade-off between achieving maximum purity in your melt and the physical ruggedness and lifespan of the crucible itself.

Making the Right Choice for Your Application

Use your primary goal to guide your final selection.

- If your primary focus is melting common non-ferrous metals like aluminum or brass: A clay-graphite or silicon carbide crucible offers the best balance of performance and cost.

- If your primary focus is high-purity metals or reactive alloys at very high temperatures: A high-purity ceramic like Alumina or Zirconia is the necessary choice to avoid contamination.

- If your primary focus is laboratory analysis requiring extreme inertness and purity: A precious metal crucible, such as one made of platinum, may be required despite its cost and lower temperature limits.

Selecting the right crucible is the foundation for a successful high-temperature process.

Summary Table:

| Material | Best For | Key Considerations |

|---|---|---|

| Clay-Graphite / Silicon Carbide | Common non-ferrous metals (Al, Brass, Bronze) | Cost-effective, good thermal conductivity |

| High-Purity Graphite | High-temperature processes in inert/vacuum atmospheres | Oxidizes in air, excellent thermal properties |

| Alumina (Aluminum Oxide) | High-purity metals, precious metals, superalloys | High melting point (>2000°C), chemically inert |

| Zirconia (Zirconium Dioxide) | Highly reactive materials, platinum-group metals | Extreme temperature resistance (>2700°C), premium cost |

Struggling to select the perfect crucible for your lab's unique needs? The wrong choice can lead to contamination, crucible failure, and wasted resources. KINTEK specializes in high-performance lab equipment and consumables, including a full range of crucibles tailored for specific metals and processes. Our experts can help you navigate the trade-offs between cost, purity, and durability to find the ideal solution for your application. Contact our team today for a personalized consultation and ensure the success of your high-temperature processes.

Visual Guide

Related Products

- High Purity Pure Graphite Crucible for Evaporation

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

People Also Ask

- What is the function of a tantalum-lined fused silica ampoule? Ensure High-Purity LBE Sample Preparation

- What can be used as a crucible for melting gold? A Guide to Graphite, Quartz, and More

- What is the best crucible for melting steel? Choose the Right Crucible for Safe & Efficient Steel Melting

- How do you clean a crucible after use? A Step-by-Step Guide for Lab Crucibles

- What are crucibles used for? A Guide to High-Temperature Containers for Melting & Analysis

- What is the maximum temperature for clay crucibles? Find the Right Crucible for Your Melting Needs

- What is the function of a graphite crucible in the FFC process? Key to High-Entropy Alloy Production

- Why Use Alumina Crucibles for TGA of Bicyclic Carbonates? Ensure Data Purity & Chemical Inertness