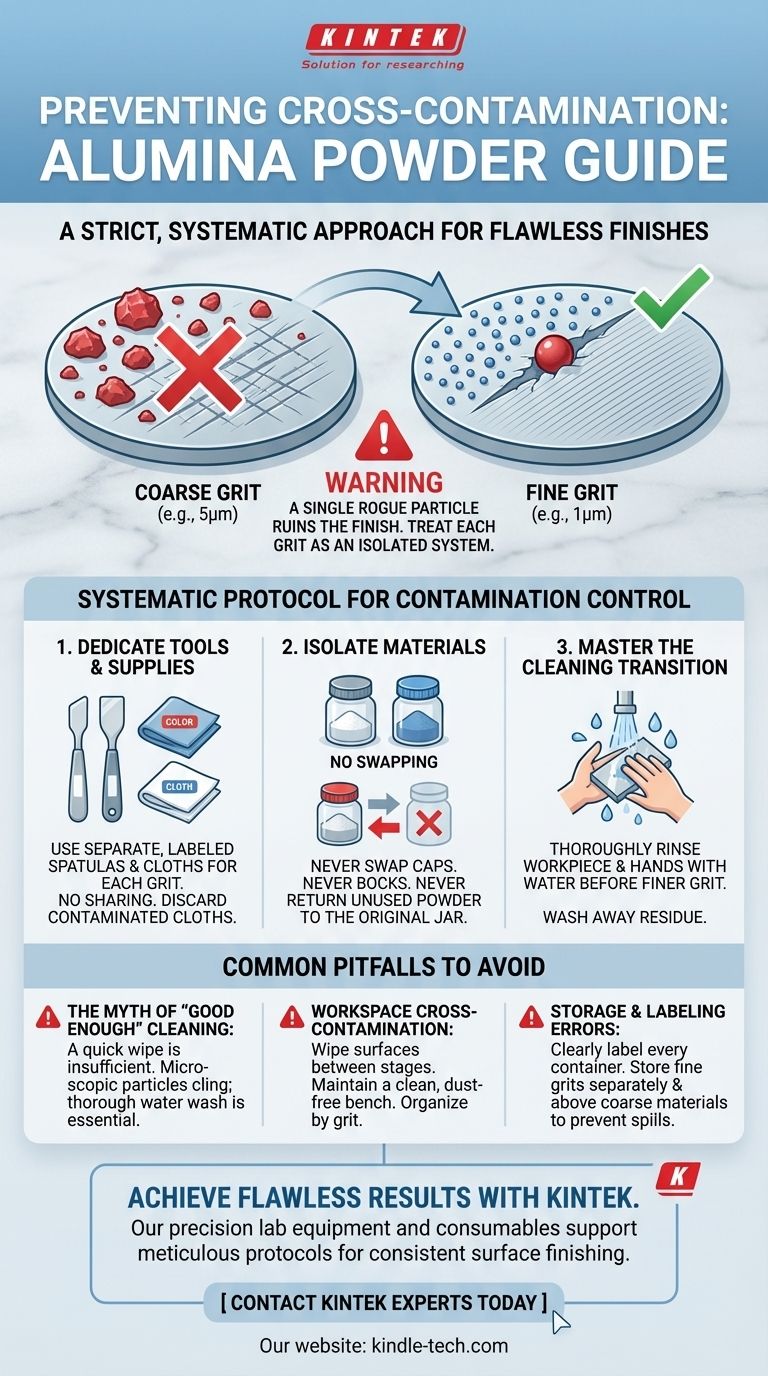

To prevent cross-contamination when using different sizes of alumina powder, you must adopt a strict, systematic approach. This involves using dedicated tools like separate spatulas for each powder, never swapping container caps, and thoroughly cleaning your workpiece and hands with water before transitioning to a finer grit.

The core principle is simple: even a single, larger abrasive particle will ruin the finer surface you are trying to create. Therefore, you must treat each grit size as an isolated system to guarantee a predictable and high-quality finish.

The Principle of Progressive Finishing

Understanding why contamination is so damaging is the first step toward preventing it. The entire purpose of using progressively finer powders is to create a specific, controlled surface.

How Abrasive Grits Work

Each size of alumina powder is designed to remove the scratches left by the previous, coarser grit. A large grit (like 5 microns) removes material quickly but leaves deep scratches. A finer grit (like 1 micron) then removes those deep scratches, replacing them with much shallower ones.

The Impact of a Rogue Particle

Introducing a single larger particle into a finer abrasive slurry is catastrophic to this process. That one coarse particle will continue to gouge the surface, creating deep scratches that the finer abrasive cannot remove.

This negates all the work done with the finer powder, leaving you with an inconsistent and flawed surface finish instead of the desired smooth, uniform one.

A Systematic Protocol for Contamination Control

To achieve a reliable outcome, you must move beyond casual cleaning and implement a clear, repeatable process. Treat your workspace like a cleanroom, where each step is deliberate.

1. Dedicate Your Tools and Supplies

The easiest way to prevent contamination is to never let different grit sizes touch the same applicator.

Use a separate, clearly labeled spatula for each container of dry powder. Do not attempt to clean one spatula to use with a different grit size.

Likewise, use a separate, dedicated polishing cloth for each stage of the process. If a larger particle becomes embedded in a cloth intended for fine polishing, that cloth is permanently contaminated and will never produce a fine finish.

2. Isolate Your Materials

Contamination often happens at the source. Maintain strict control over your powder containers.

Never swap caps between containers. A few stray particles from inside a cap are all it takes to contaminate an entire jar of fine powder.

Never pour unused powder back into its original container. Once the powder has left the jar, consider it potentially contaminated and do not return it.

3. Master the Cleaning Transition

The moment you switch from a coarser to a finer grit is the most critical point for contamination.

Before moving to the next finer stage, you must thoroughly clean the workpiece (e.g., the electrode) and your hands with water. Rinsing is essential to physically wash away all residual abrasive particles from the previous step.

Common Pitfalls to Avoid

Even with a good system, small oversights can lead to failure. Being aware of these common mistakes is crucial for maintaining process integrity.

The Myth of "Good Enough" Cleaning

A quick wipe with a dry cloth or a brief rinse is not sufficient. Abrasive particles are microscopic and cling to surfaces and skin. You must perform a thorough washing with flowing water to ensure all coarser particles are removed from the workpiece, your hands, and the immediate work area.

Workspace Cross-Contamination

Your tools and workpiece are not the only sources of contamination. A dusty or disorganized workbench can easily introduce stray particles.

Wipe down your work surface between stages. Be mindful of airborne dust, especially if coarse grinding is performed in the same room. A clean, organized workspace is a prerequisite for a clean, high-quality finish.

Storage and Labeling Errors

Improperly labeled containers are a common source of error. Ensure every powder container, slurry bottle, and polishing cloth is clearly and permanently marked with its grit size. Store finer grit materials separately from, and ideally above, coarser grit materials to prevent spills from causing contamination.

Making the Right Choice for Your Process

Your required level of diligence depends directly on your desired outcome.

- If your primary focus is a flawless, mirror-like finish (e.g., metallography, optics): Absolute separation is non-negotiable. Use entirely different sets of tools and polishing cloths for your final one or two finishing steps.

- If your primary focus is general shaping or deburring: While good practice is still important for consistency, a minor contamination event is less catastrophic to the final outcome.

By implementing this disciplined approach, you gain complete control over your surface finishing process.

Summary Table:

| Prevention Measure | Key Action | Purpose |

|---|---|---|

| Dedicated Tools | Use separate, labeled spatulas and cloths for each grit size. | Prevents physical transfer of abrasive particles between grits. |

| Material Isolation | Never swap container caps or return unused powder to jars. | Protects the integrity of fine powders from rogue coarse particles. |

| Thorough Cleaning | Rinse workpiece and hands with water before switching to a finer grit. | Washes away all residual abrasive particles from previous steps. |

| Workspace Management | Wipe down surfaces and store fine grits separately from coarse ones. | Minimizes risk of airborne or environmental contamination. |

Achieve Flawless Finishing Results with KINTEK's Precision Lab Equipment

Struggling with inconsistent surface finishes due to cross-contamination? KINTEK specializes in high-quality lab equipment and consumables designed to support meticulous processes like abrasive powder handling. Our range includes dedicated tools, cleanroom supplies, and storage solutions that help you maintain the strict isolation protocols necessary for perfect results.

Let us help you enhance your lab's efficiency and outcome reliability. Contact our experts today to discuss your specific needs and discover how KINTEK's products can bring precision and consistency to your surface finishing workflow.

Visual Guide

Related Products

- High Purity Alumina Granulated Powder for Engineering Advanced Fine Ceramics

- Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

- Custom PTFE Teflon Parts Manufacturer Corrosion Resistant Cleaning Rack Flower Basket

- Custom PTFE Teflon Parts Manufacturer for Hollow Cleaning Basket and Rack Carrier

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

People Also Ask

- How high temperature can ceramic withstand? A Guide to Extreme Heat Performance

- What are the examples of ceramic powder? A Guide to Oxide and Non-Oxide Materials

- What is the maximum temperature for alumina tube? Unlock Its Full Potential with High Purity

- What are the process advantages of selecting an alumina plate for CuO nanofilm synthesis? Achieve Superior Purity

- What is the maximum operating temperature of alumina? The Critical Role of Purity and Form