Handling a copper sulfate reference electrode correctly is a matter of both procedure and principle. To ensure accurate measurements, you must prevent physical damage, regularly calibrate its potential, keep the porous plug clean, and store it in a saturated copper sulfate solution away from direct sunlight and temperature swings. These steps are critical for maintaining the electrode as a stable electrochemical reference.

The core purpose of a reference electrode is to provide a stable, known potential. This stability is not automatic; it is the direct result of meticulous handling, preparation, and maintenance. Your precautions are not just about protecting the device—they are about guaranteeing the integrity of your data.

Understanding the Electrode's Function

A copper sulfate electrode (CSE) is a fundamental tool in electrochemistry and corrosion control. Its value comes from its ability to provide a consistent voltage baseline.

What is a Reference Electrode?

A reference electrode is a stable half-cell of an electrochemical system. It is physically impossible to measure the absolute potential of a single electrode.

Instead, we measure the potential difference between a working electrode (like a pipeline buried in soil) and a reference electrode. Because the reference potential is constant, any change in the measured voltage is attributed entirely to the working electrode.

How It Generates a Stable Potential

The electrode's stability comes from the equilibrium of a simple chemical reaction. A copper rod is immersed in a saturated copper sulfate (CuSO₄) solution.

This setup creates a predictable electrochemical process where copper ions (Cu²⁺) and copper metal are in balance, generating a stable potential. Maintaining this saturation is non-negotiable for an accurate reference.

Pre-Use Inspection and Preparation

Before every use, a thorough check is required to prevent inaccurate readings. An electrode that is not properly prepared will produce unreliable data.

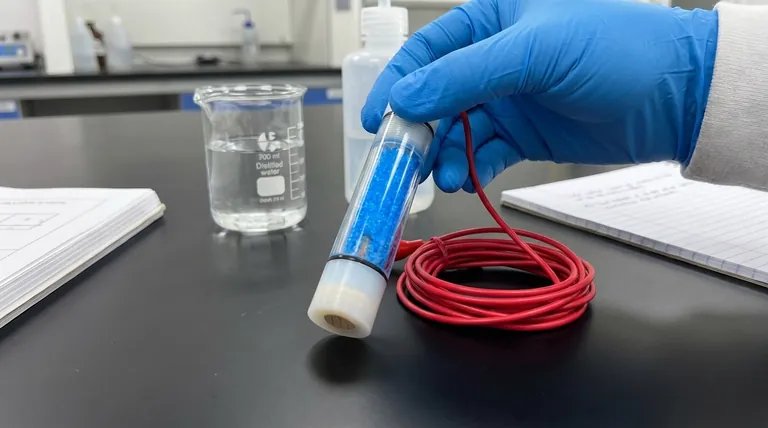

Inspect for Physical Integrity

Visually inspect the electrode's body for any cracks or physical damage. Check that the cap is well-sealed and that the connecting wire is not frayed, aged, or damaged. Repair or replace any compromised components.

Ensure Solution Saturation

The solution inside the electrode must be saturated. You should be able to see excess, undissolved copper sulfate crystals in the solution chamber, which confirms saturation.

If the solution is low or not saturated, refill it with distilled water to dissolve the crystals, or add a pre-mixed saturated CuSO₄ solution.

Clean the Porous Tip

The porous plug at the bottom of the electrode is the ionic bridge to the environment you are measuring. Carefully clean any dirt, mud, or solid residue from this tip. A clogged tip will interrupt the electrical circuit and prevent a valid measurement.

Stabilize and Calibrate

After preparing the solution, immerse the electrode's tip in the solution to allow its potential to stabilize.

Finally, calibrate the electrode by measuring its potential against a known standard. If the reading deviates significantly from the expected value, the electrode is not functioning correctly and may need to be replaced.

Precautions During Field or Lab Use

During the measurement process, your handling directly impacts the quality of the reading.

Avoid Physical Damage

Protect the electrode from being dropped, squeezed, or subjected to heavy collisions or vibrations. The body, while often made of durable plastic, can crack, and the internal components are sensitive.

Protect the Porous Plug

The porous plug is the most common point of failure. Ensure it makes good contact with the soil or electrolyte but is not forced into a position where it could become clogged with debris or damaged.

Ensure Electrical Safety

When working near power sources, ensure any metal stands or clamps are properly insulated. Always wear appropriate personal protective equipment (PPE), such as insulating gloves, and never touch electrodes or metal components with wet hands.

Post-Use Maintenance and Storage

Proper care after use ensures the electrode's longevity and readiness for the next measurement.

Clean the Electrode Body

Promptly clean the electrode after use. Wipe the outer casing with a soft, damp cloth to remove any surface dirt or impurities.

Carefully Clean the Porous Plug

The porous plug at the bottom requires careful attention. Clean it gently to remove any attached soil or contaminants. Never use sharp objects, as scratches can permanently damage the membrane.

Check and Refill the Solution

Check the level of the copper sulfate solution. If it has fallen below the specified level, top it off with saturated copper sulfate solution.

Store in a Stable Environment

For long-term storage, keep the electrode upright in a container with a small amount of saturated copper sulfate solution, ensuring the tip remains moist. Store it in a cool, dry place away from direct sunlight and significant temperature fluctuations.

Common Pitfalls to Avoid

Understanding common failure modes is key to maintaining data integrity. An uncalibrated or contaminated electrode can give you a precise but wildly inaccurate number, which is often more dangerous than no data at all.

Ignoring Contamination

The electrode's electrolyte must remain pure. Contamination, especially from chlorides (found in saltwater, de-icing salts, and some soils), can significantly alter the reference potential, leading to incorrect readings. Always use a different type of reference electrode (like Silver/Silver Chloride) in high-chloride environments.

The "Set and Forget" Fallacy

An electrode's potential can drift over time. Regular calibration is not optional. Trusting an uncalibrated electrode is a critical mistake that invalidates measurement results.

Overlooking Temperature Effects

Potential is temperature-dependent. While the CSE is relatively robust, conducting measurements or storing the electrode in environments with extreme temperature fluctuations will compromise its stability and the accuracy of your readings.

Making the Right Choice for Your Goal

Your handling procedures should align with your primary objective.

- If your primary focus is high-accuracy laboratory work: Prioritize rigorous and frequent calibration, precise temperature control, and ensuring zero contamination of the internal solution.

- If your primary focus is field-based corrosion surveys: Emphasize physical durability, pre-use inspection, ensuring the porous tip is clean and makes good contact, and always carrying a recently calibrated spare.

- If your primary focus is long-term electrode longevity: Focus on meticulous post-use cleaning, proper refilling of the saturated solution, and correct storage in a stable environment.

By treating the electrode not as a simple probe but as a sensitive scientific instrument, you ensure it remains a consistently reliable tool for your work.

Summary Table:

| Precaution Phase | Key Action | Why It Matters |

|---|---|---|

| Pre-Use | Inspect for damage, ensure solution saturation, clean porous plug | Prevents inaccurate readings from physical defects or contamination |

| During Use | Avoid physical damage, protect porous plug, ensure electrical safety | Maintains electrode integrity and user safety during measurement |

| Post-Use | Clean body & porous plug, refill solution, store in stable environment | Ensures electrode longevity and readiness for future use |

| Common Pitfalls | Avoid contamination (e.g., chlorides), calibrate regularly, control temperature | Prevents potential drift and inaccurate data |

Ensure your laboratory's electrochemical measurements are always accurate and reliable. Proper handling of reference electrodes is critical for data integrity in corrosion monitoring, material testing, and research. KINTEK specializes in high-quality lab equipment and consumables, including durable reference electrodes and maintenance solutions tailored for laboratory needs. Let our experts help you select the right tools and optimize your protocols. Contact KINTEK today to discuss how we can support your lab's precision and efficiency!

Visual Guide

Related Products

- Copper Sulfate Reference Electrode for Laboratory Use

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Metal Disc Electrode Electrochemical Electrode

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Reference Electrode Calomel Silver Chloride Mercury Sulfate for Laboratory Use

People Also Ask

- What are the available specifications for platinum sheet electrodes? Find the Perfect Fit for Your Electrochemical Needs

- What are the available specifications for the gold plate electrode? Optimize Your Electrochemical Analysis

- What is the function of a three-electrode system in platinum nanoparticle deposition? Achieve Precision Control

- Which properties of graphite are most important for its use as high temperature electrodes? Unlock Unmatched Performance in Extreme Heat

- What preparation steps are required for the electrodes? Ensure High-Accuracy Electrochemical Analysis

- What is the primary function of gas diffusion electrodes (GDEs)? Boost Mass Transfer in CO2 Electrolysis

- What is the purity of the platinum wire/rod electrode? The 99.99% Standard for Reliable Electrochemistry

- How should a copper sulfate reference electrode be maintained? Ensure Accurate Electrochemical Measurements