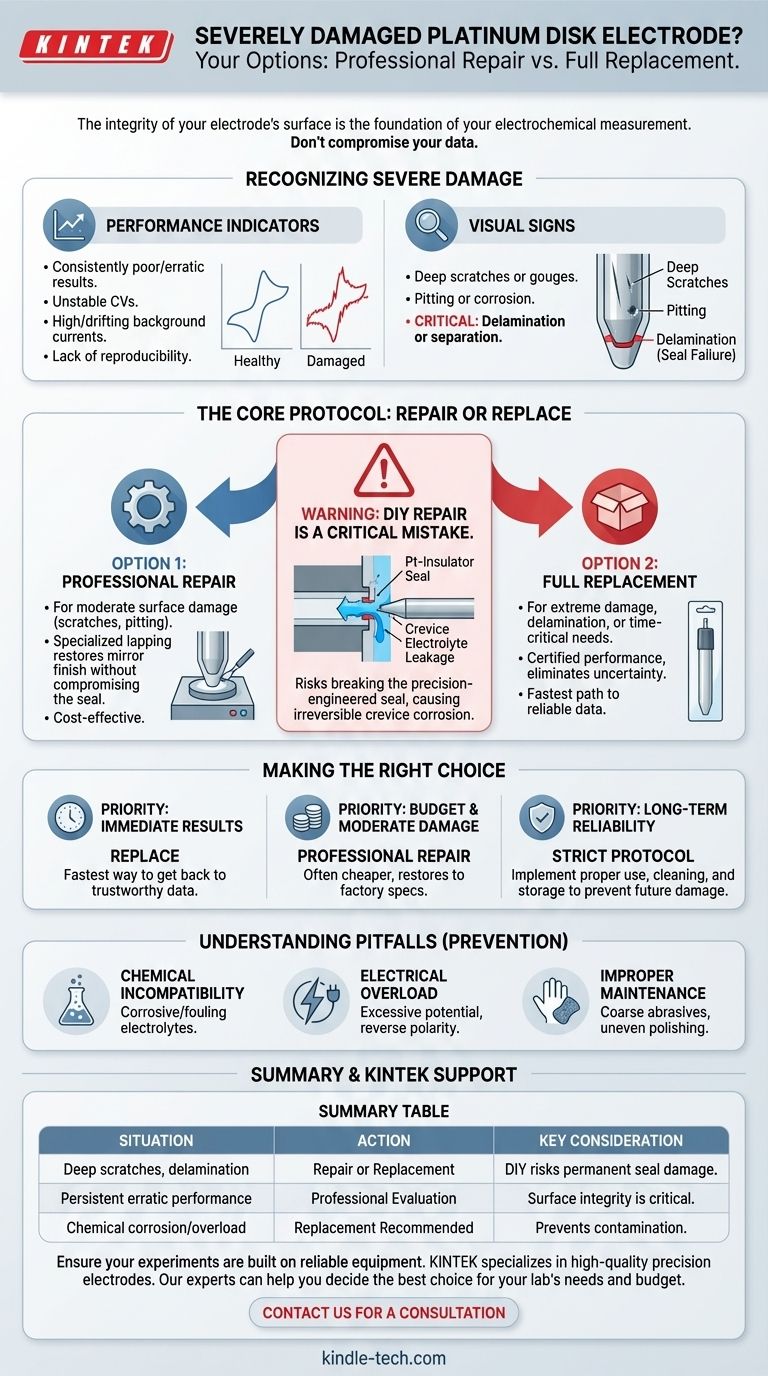

When a platinum disk electrode is severely damaged, your only two viable options are to send it for professional repair or to replace it entirely. Any attempts at self-repair beyond standard polishing risk causing permanent, unfixable damage to the instrument.

The integrity of your electrode's surface is not a minor detail; it is the foundation of your entire electrochemical measurement. A compromised surface yields compromised data, making the decision to professionally repair or replace a damaged electrode a critical step in preserving the validity of your research.

Recognizing Irreparable Damage

Before deciding on a course of action, you must first distinguish between minor issues solvable with routine polishing and severe damage that requires professional intervention.

Performance-Based Indicators

An electrode's performance is the most sensitive indicator of its health. Look for consistently poor or erratic results, such as unstable cyclic voltammograms (CVs), high and drifting background currents, or a complete lack of reproducibility between runs. If these issues persist after proper electrochemical cleaning and mechanical polishing, it points to a deeper problem.

Visual Signs of Severe Damage

Visible inspection can reveal issues that polishing cannot fix. These include deep scratches or gouges on the platinum surface, pitting or corrosion, and—most critically—any sign of delamination or separation between the platinum disk and its insulating shroud (commonly PEEK or Teflon).

The Core Protocol: Repair or Replace

Once you've determined the damage is severe, the "do-it-yourself" approach is no longer an option. The choice narrows to professional repair or full replacement.

Why DIY Repair is a Critical Mistake

The primary warning against self-repair is to prevent damage to the seal between the platinum disk and the insulating body. This seal is precision-engineered. Attempting to disassemble the electrode or use aggressive, non-standard tools can break this seal, creating a microscopic crevice. Electrolyte will inevitably seep into this gap, leading to crevice corrosion and contaminating all future experiments with unpredictable ionic leakage. This type of damage is irreversible.

When to Seek Professional Repair

A professional service has specialized lapping and polishing equipment that can resurface a moderately damaged electrode to its original mirror finish without compromising the critical Pt-insulator seal. This can be a cost-effective option if the main body of the electrode is intact and the damage is confined to the disk's surface.

The Case for Full Replacement

In cases of extreme physical damage, delamination, or when the cost and downtime of repair are prohibitive, replacement is the most direct path to reliable data. A new electrode comes with certified performance, eliminating any uncertainty that might linger after a repair.

Understanding the Pitfalls: How Damage Occurs

Preventing damage is always preferable to reacting to it. Understanding the common failure modes is key to extending the life of your electrode and ensuring data quality.

Chemical Incompatibility

While platinum is highly inert, it is not invincible. Using it in electrolytes containing substances that can corrode, poison, or foul the surface is a primary cause of performance degradation. Always verify that your experimental conditions and chosen electrolyte are compatible with platinum.

Electrical Overload

Improper connection or operation of your potentiostat can inflict serious damage. Applying excessive potentials, reversing the electrode's polarity, or creating a short circuit can cause pitting or irreversible changes to the platinum surface morphology. Always double-check your connections and operate within the electrode's specified limits.

Improper Maintenance

Routine polishing is necessary, but improper technique can cause more harm than good. Using abrasive materials that are too coarse can create deep scratches, while polishing unevenly can round the edges of the disk, altering its defined geometric area and skewing quantitative results.

Making the Right Choice for Your Goal

Your decision should be guided by your specific priorities, whether they are budgetary, time-sensitive, or purely focused on data integrity.

- If your primary focus is immediate, guaranteed results: Replace the electrode. A new, certified instrument is the fastest way to get back to collecting trustworthy data.

- If your primary focus is budget and the damage is moderate: Send the electrode for professional repair and evaluation. This is often cheaper than a replacement and can restore the electrode to factory specifications.

- If your primary focus is long-term reliability: Implement a strict lab protocol for electrode use, cleaning, and storage to prevent future damage, regardless of whether you repair or replace the current one.

Ultimately, you must treat your electrode as the precision instrument it is, as the quality of your results depends directly on its condition.

Summary Table:

| Situation | Recommended Action | Key Consideration |

|---|---|---|

| Deep scratches, pitting, or delamination | Professional Repair or Replacement | DIY repair risks permanent seal damage |

| Persistent erratic performance after cleaning | Professional Evaluation | Surface integrity is critical for data validity |

| Chemical corrosion or electrical overload | Replacement Recommended | Prevents future experimental contamination |

Ensure your electrochemical experiments are built on a foundation of reliable equipment. KINTEK specializes in high-quality lab equipment and consumables, including precision electrodes. If you're facing issues with your platinum disk electrode, our experts can help you decide whether professional repair or replacement is the best choice for your lab's needs and budget. Don't compromise your research—contact us today for a consultation and get back to producing valid, reproducible data with confidence.

Visual Guide

Related Products

- Rotating Platinum Disk Electrode for Electrochemical Applications

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Gold Disc Electrode

- Platinum Auxiliary Electrode for Laboratory Use

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

People Also Ask

- How should a platinum wire/rod electrode be cleaned before use? A Guide to Reliable Electrochemical Data

- What is the difference between ring disk electrode and rotating disk electrode? Unlock Deeper Electrochemical Insights

- What is the common role of a platinum disk electrode? A Guide to Its Primary Use as a Working Electrode

- What are the specifications of the Platinum-Titanium Functional Electrode? Maximize Electrochemical Performance

- What is the application of RRDE? Unlock Quantitative Catalyst and Reaction Insights