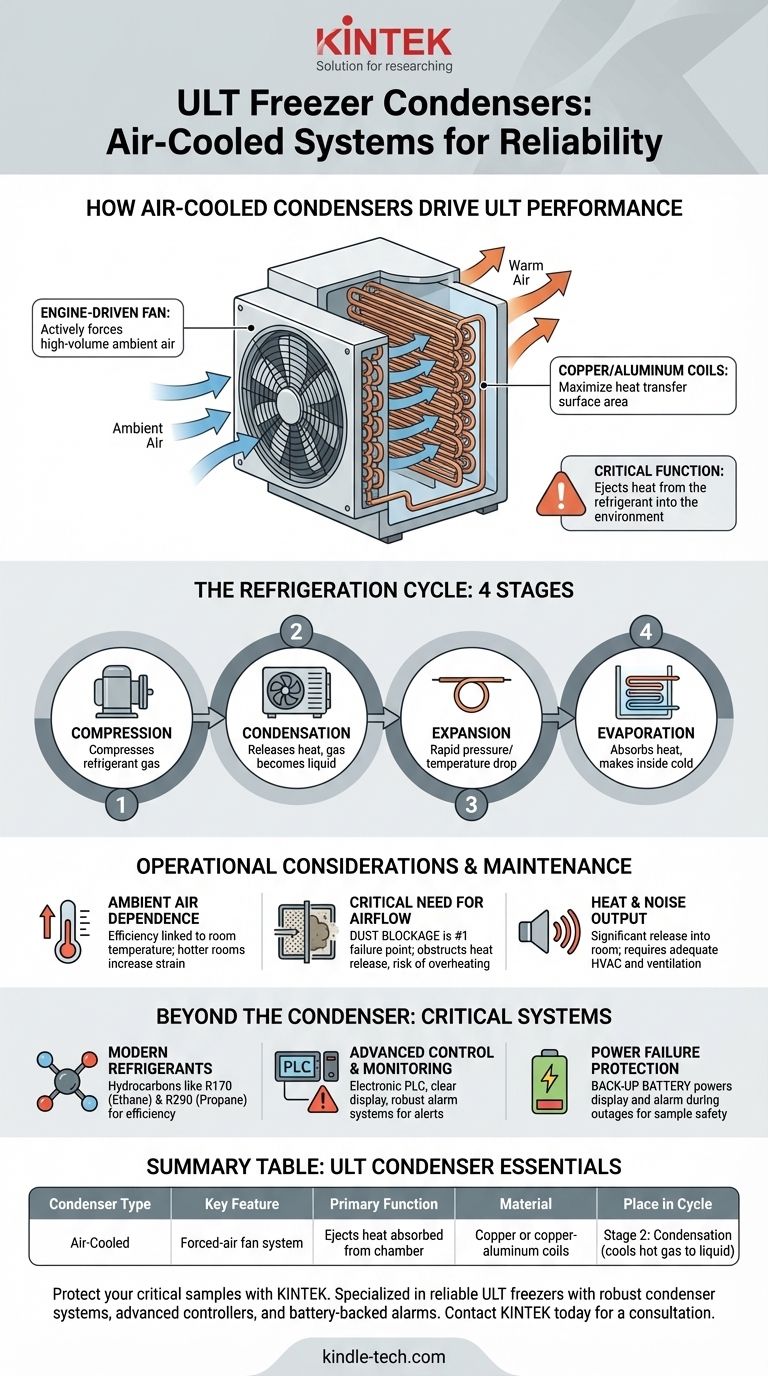

At their core, ultra-low temperature (ULT) freezers overwhelmingly rely on air-cooled condensers to function. These systems use engine-driven fans to force ambient air over a series of coils, efficiently removing heat from the refrigerant and releasing it into the surrounding environment. This method is a foundational part of the refrigeration cycle that allows these specialized freezers to achieve and maintain temperatures as low as -86°C.

While the condenser type is straightforward, the real challenge is understanding its role within the entire refrigeration system. The reliability of a ULT freezer depends less on the specific type of condenser and more on how well it is integrated with other critical components and maintained within its operating environment.

How Air-Cooled Condensers Drive ULT Performance

The condenser is the component responsible for ejecting the heat that the freezer has absorbed from its insulated chamber. In a ULT freezer, this process must be exceptionally efficient and reliable.

The Principle of Heat Exchange

A ULT freezer works by moving heat from the inside to the outside. The refrigerant absorbs heat inside the freezer (becoming a gas), travels to the condenser, and then releases that heat into the laboratory as it is cooled back into a liquid. The air-cooled condenser is the radiator for this entire system.

The Role of Forced Air

To maximize the rate of heat transfer, these systems do not rely on passive cooling. An engine-driven fan actively forces a high volume of air across the condenser coils. This forced circulation is critical for quickly dissipating the intense heat load generated when maintaining ultra-low temperatures.

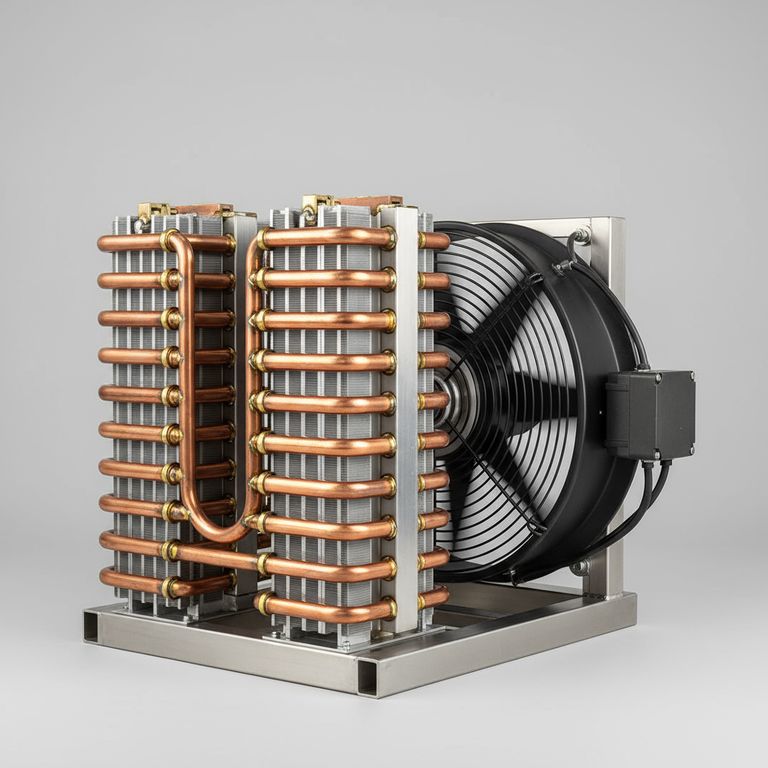

Materials and Construction

Condensers in ULT freezers are built from materials with high thermal conductivity. They typically consist of tubular batteries made of copper or copper-aluminum. This construction provides a large surface area, maximizing contact with the cooling air and ensuring the refrigerant releases its heat efficiently.

The Condenser's Place in the Refrigeration Cycle

Understanding the condenser requires seeing its place in the complete refrigeration loop. It is one of four critical stages.

1. Compression

The cycle begins when the compressor takes in low-pressure refrigerant gas and compresses it into a hot, high-pressure gas.

2. Condensation

This hot gas flows into the air-cooled condenser. As the fan blows cooler ambient air over the coils, the gas releases its heat and condenses back into a high-pressure liquid.

3. Expansion

This liquid refrigerant then passes through a very narrow capillary tube, causing a rapid drop in pressure and temperature.

4. Evaporation

The now extremely cold, low-pressure liquid flows into the evaporator coils inside the freezer chamber. Here, it absorbs heat from the chamber's interior, boiling back into a gas and making the inside of the freezer cold. The cycle then repeats.

Understanding the Trade-offs and Maintenance

While effective, the reliance on air-cooled condensers presents operational considerations that are critical for performance and longevity.

Dependence on Ambient Air

The efficiency of an air-cooled condenser is directly linked to the temperature of the room it is in. A hotter room means the condenser must work harder to release heat, increasing energy consumption and stress on the compressor.

The Critical Need for Airflow

The single most common point of failure related to the condenser is blockage and dust. If the condenser coils or air vents become clogged with dust, airflow is restricted. This traps heat, forcing the system to run constantly and eventually leading to overheating and catastrophic compressor failure.

Heat and Noise Output

By design, a ULT freezer's condenser releases a significant amount of heat and noise into the room. This must be factored into lab design, requiring adequate ventilation or HVAC capacity to manage the thermal load and acoustic environment.

Beyond the Condenser: Other Critical Systems

Focusing only on the condenser misses other key factors that define a modern ULT freezer's reliability.

Efficient and Modern Refrigerants

The most efficient and environmentally friendly ULT freezers use specialized refrigerant fluids. These are typically hydrocarbons like R170 (Ethane) and R290 (Propane), which have excellent thermodynamic properties for achieving ultra-low temperatures.

Advanced Control and Monitoring

Reliability hinges on sophisticated control systems. The best units feature an electronic PLC (Programmable Logic Controller) and a clear display for all parameters. Crucially, they include robust alarm systems that can remotely alert staff in case of a power outage or temperature deviation.

Power Failure Protection

To ensure sample integrity during a power outage, a back-up battery is essential. This battery powers the temperature display and alarm system, ensuring you are aware of the freezer's status even when the main power is off.

Making the Right Choice for Your Goal

The type of condenser is standard across most ULT freezers; therefore, your decision should be based on the systems that support it.

- If your primary focus is sample safety: Prioritize a freezer with a robust, battery-backed alarm system and a modern electronic controller.

- If your primary focus is long-term reliability: Implement a strict, regular cleaning schedule for the condenser coils and air filter to ensure unobstructed airflow.

- If your primary focus is operational efficiency: Place the freezer in a well-ventilated, climate-controlled room to reduce the strain on the condenser and lower energy costs.

Ultimately, protecting your valuable samples depends on viewing the ULT freezer as an integrated system, where proper maintenance and environmental control are just as important as the hardware itself.

Summary Table:

| Condenser Type | Key Feature | Primary Function |

|---|---|---|

| Air-Cooled | Forced-air fan system | Ejects heat absorbed from the freezer chamber |

| Material | Copper or copper-aluminum coils | Maximizes heat transfer efficiency |

| Place in Cycle | Stage 2: Condensation | Cools hot refrigerant gas back into a liquid |

Protect your critical samples with a ULT freezer designed for maximum reliability. KINTEK specializes in laboratory equipment and consumables, providing ultra-low temperature freezers with robust air-cooled condenser systems, advanced electronic controllers, and battery-backed alarms to ensure your samples remain safe. Our experts can help you select the right model for your lab's specific needs and environment. Contact KINTEK today to learn more and get a consultation.

Visual Guide

Related Products

- 5L Chilling Circulator Cooling Water Bath Circulator for Low Temperature Constant Temperature Reaction Bath

- Low-Temperature Water-Cooled Touchscreen Vibratory Ultrafine Pulverizer

- 10L Chilling Circulator Cooling Water Bath Low Temperature Constant Temperature Reaction Bath

- Vacuum Cold Trap Direct Cold Trap Chiller

- Custom PTFE Teflon Parts Manufacturer PTFE Beaker and Lids

People Also Ask

- Why are internal cooling coils used after hydrothermal treatment? Unlock Higher Yields in Biomass Processing

- How do cooling systems impact bio-oil collection? Maximize Pyrolysis Yield with Precision Multi-Stage Quenching

- Why is a circulating water cooling system required for photocatalytic hydrogen peroxide? Stability and Yield Explained

- What is the necessity of using a cooling circulation system after corncob hydrothermal reaction? Maximize Your Yield.

- What is the primary function of water baths and chillers? Mastering Precise Thermal Stability for Liquid Samples