At its core, the type of deposition that relies on a high vacuum is known as Physical Vapor Deposition (PVD). This category encompasses several techniques where a solid or liquid material is vaporized in a vacuum chamber, transported across that vacuum, and then condensed onto a substrate to form a high-quality thin film. The vacuum is not an incidental condition; it is the fundamental enabler of the entire process.

The essential role of a high vacuum in deposition is to create an ultra-clean environment. By removing virtually all air and water molecules, the vacuum ensures that coating particles can travel from their source to the target without colliding with or reacting to contaminants, which is critical for creating pure, dense, and highly adherent films.

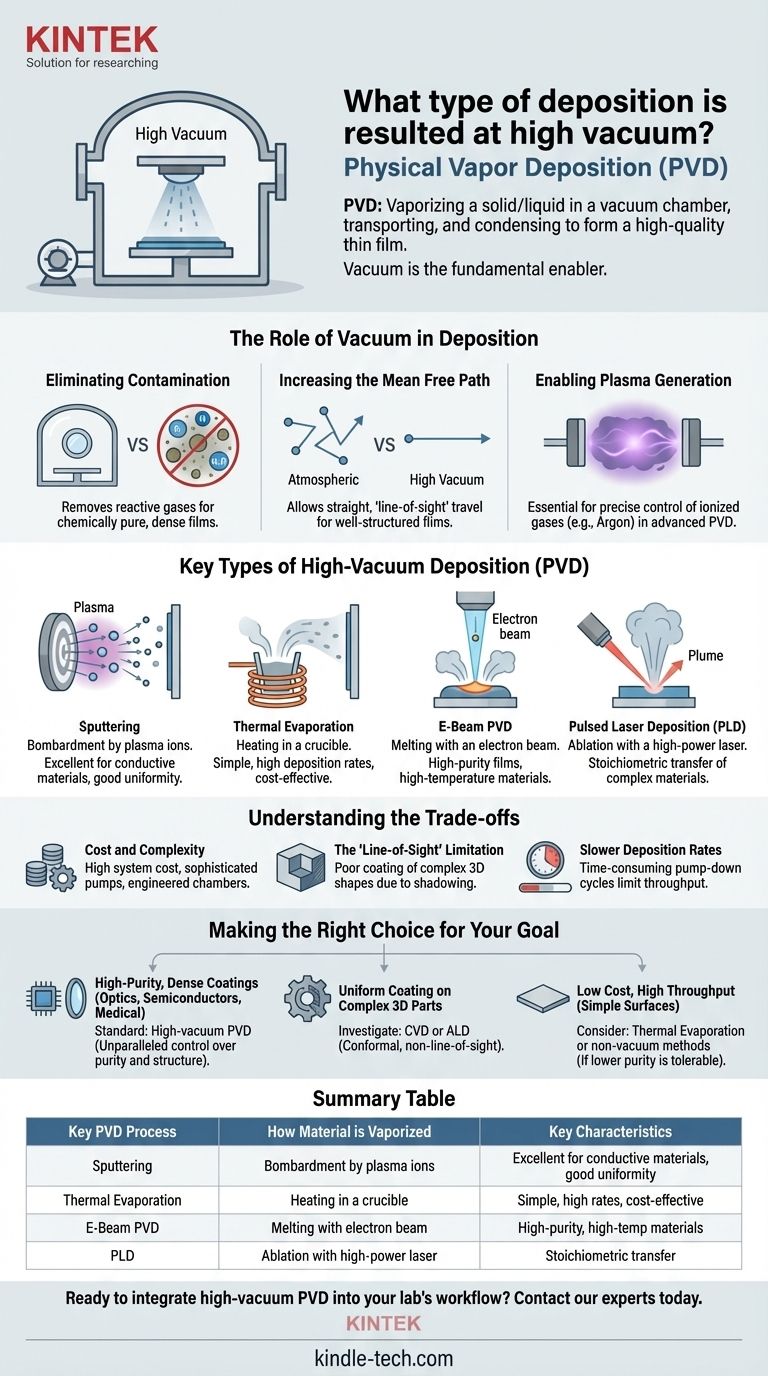

The Role of Vacuum in Deposition

Understanding why a vacuum is used is more important than simply naming the process. The vacuum fundamentally alters the physics of the deposition environment, enabling a level of control that is impossible at atmospheric pressure.

Eliminating Contamination

Atmospheric air is filled with reactive gases like oxygen, nitrogen, and water vapor. If these particles were present during deposition, they would readily react with the vaporized coating material.

This creates unwanted compounds, such as oxides and nitrides, within the film. A high vacuum removes these contaminants, ensuring the deposited film is chemically pure and possesses the intended properties.

Increasing the Mean Free Path

Mean free path is the average distance a particle travels before colliding with another particle. In the atmosphere, this distance is incredibly short, measured in nanometers.

A high vacuum increases the mean free path to meters, often longer than the chamber itself. This allows the vaporized coating atoms to travel in a straight, uninterrupted line from the source to the substrate. This "line-of-sight" trajectory is essential for creating dense, well-structured films.

Enabling Plasma Generation

Many advanced PVD processes, such as sputtering, use a plasma to generate coating vapor. A plasma is a state of matter where a gas is energized until its atoms become ionized.

These low-pressure plasmas can only be created and sustained in a vacuum environment. The vacuum allows for the precise control of the gas (typically an inert gas like Argon) used to create the plasma.

Key Types of High-Vacuum Deposition

Physical Vapor Deposition (PVD) is a family of processes. While all rely on a vacuum, they differ in how they vaporize the source material.

Sputtering

In sputtering, a target made of the coating material is bombarded by high-energy ions from a plasma. This bombardment acts like an atomic-scale sandblaster, ejecting or "sputtering" atoms from the target. These atoms then travel through the vacuum and deposit onto the substrate.

Thermal Evaporation

This is one of the simplest PVD methods. The source material is placed in a crucible and heated in the vacuum until it evaporates (for liquids) or sublimates (for solids). This vapor then travels through the chamber and condenses on the cooler substrate, much like steam condensing on a cold mirror.

Electron-Beam PVD and PLD

More advanced techniques use focused energy sources. Electron-Beam PVD (E-Beam PVD) uses a high-energy beam of electrons to melt and evaporate the source material. Pulsed Laser Deposition (PLD) uses a high-power laser to ablate material from a target, creating a plume of vapor that coats the substrate.

Understanding the Trade-offs

While essential for high performance, vacuum-based deposition is not a universal solution. It comes with significant engineering and practical challenges.

Cost and Complexity

High-vacuum systems are expensive to build and operate. They require a sequence of pumps (e.g., mechanical roughing pumps and high-vacuum turbomolecular or cryogenic pumps), sophisticated pressure gauges, and precisely engineered chambers, all of which represent a significant investment.

The "Line-of-Sight" Limitation

Because the coating particles travel in straight lines, PVD processes are poor at coating complex, three-dimensional shapes. Areas that are not in the direct line-of-sight of the source will receive little to no coating, a phenomenon known as shadowing.

Slower Deposition Rates

Pump-down cycles to achieve a high vacuum can be time-consuming. Combined with often slow deposition rates, this can limit the throughput of PVD systems, making them less suitable for certain high-volume manufacturing applications compared to atmospheric processes.

Making the Right Choice for Your Goal

Selecting a deposition method depends entirely on the required properties of the final film.

- If your primary focus is high-purity, dense coatings for optics, semiconductors, or medical implants: High-vacuum PVD is the standard because it provides unparalleled control over film purity and structure.

- If you need to coat complex 3D parts uniformly: You should investigate processes like Chemical Vapor Deposition (CVD) or Atomic Layer Deposition (ALD), which are not strictly line-of-sight and can produce highly conformal coatings.

- If your priority is low cost and high throughput on simple surfaces: Simpler PVD methods like thermal evaporation or non-vacuum techniques might be more appropriate, provided the application can tolerate lower film purity and density.

Ultimately, using a high vacuum is a deliberate engineering choice to control the deposition environment at the atomic level, enabling the creation of advanced thin-film materials.

Summary Table:

| Key PVD Process | How Material is Vaporized | Key Characteristics |

|---|---|---|

| Sputtering | Bombardment by plasma ions | Excellent for conductive materials, good uniformity |

| Thermal Evaporation | Heating in a crucible | Simple, high deposition rates, cost-effective |

| E-Beam PVD | Melting with an electron beam | High-purity films, high-temperature materials |

| Pulsed Laser Deposition (PLD) | Ablation with a high-power laser | Stochiometric transfer of complex materials |

Ready to integrate high-vacuum PVD into your lab's workflow?

At KINTEK, we specialize in providing state-of-the-art lab equipment, including PVD systems, to meet the precise needs of research and development laboratories. Our expertise ensures you get the right solution for creating high-purity, high-performance thin films for applications in semiconductors, optics, and medical devices.

Let's discuss your project requirements and how our equipment can accelerate your innovation.

Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use

- Why is a heated laboratory hydraulic press necessary for composite laminates? Achieve Void-Free Structural Integrity

- What is hot press forging? Creating Complex, High-Strength Metal Components

- What is hot press lamination? The Ultimate Guide to Strong, Durable Material Bonding