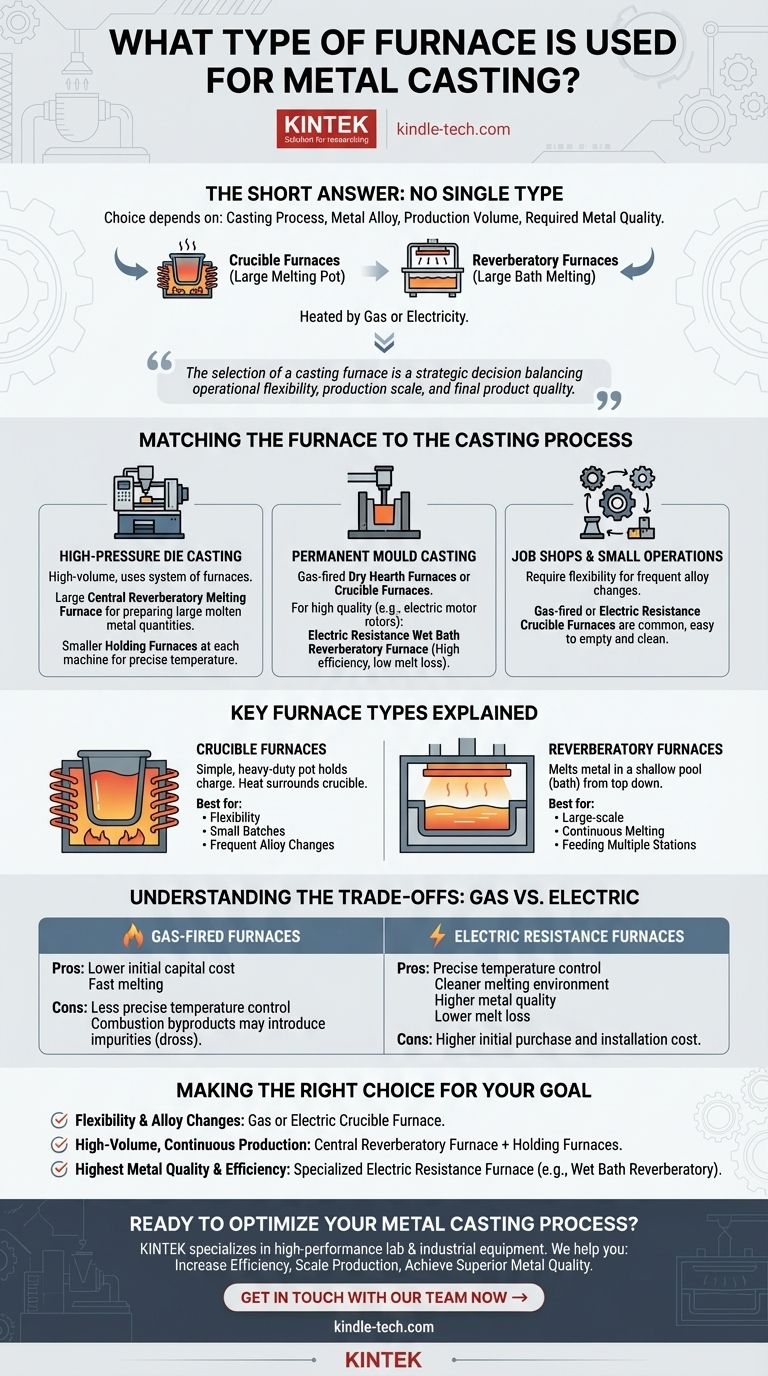

The short answer is that there is no single type of furnace for metal casting; the choice depends entirely on the casting process, the metal alloy, production volume, and required metal quality. The most common categories are crucible furnaces, which act like a large melting pot, and reverberatory furnaces, where metal is melted in a larger bath. These can be heated by either gas or electricity, each with distinct advantages.

The selection of a casting furnace is a strategic decision that balances operational flexibility, production scale, and final product quality. Understanding the core function of each furnace type allows you to match the technology to your specific manufacturing goal.

Matching the Furnace to the Casting Process

The type of furnace used is directly tied to the demands of the specific casting method. High-volume processes have different needs than smaller, more specialized operations.

For High-Pressure Die Casting

High-pressure die casting is a high-volume process that often uses a system of furnaces. It's common to see a large central reverberatory melting furnace to prepare large quantities of molten metal.

This metal is then transferred to smaller holding furnaces at each casting machine. These can be low-energy electric or gas-fired units that keep the metal at the precise temperature needed for casting.

For Permanent Mould Casting

Permanent mould applications typically use either gas-fired dry hearth furnaces or crucible furnaces heated by gas or electricity.

For applications where metal purity and quality are paramount, such as casting electric motor rotors, a specialized furnace is used. An electric resistance wet bath reverberatory furnace is preferred for its high energy efficiency (60-65%) and its ability to produce superior quality metal with very low melt loss.

For Job Shops and Small Operations

Smaller foundries or "job shops" require flexibility above all else. They often need to switch between different metal alloys frequently for various client projects.

In these environments, gas-fired or electric resistance crucible furnaces are the most common choice. Their design makes them relatively easy to empty and clean, which is essential when changing alloys.

Key Furnace Types Explained

While many variations exist, casting furnaces generally fall into two main families based on how they contain and heat the metal.

Crucible Furnaces

Think of a crucible furnace as a simple, heavy-duty pot (the crucible) that holds the metal charge. The heat source—either gas burners or electric resistance coils—surrounds the crucible to melt the contents.

Their key advantage is flexibility. Because the metal is fully contained, it's ideal for melting smaller batches and for operations that require frequent changes between different alloys.

Reverberatory Furnaces

A reverberatory furnace melts metal in a shallow pool, or "bath," within a large, rectangular chamber. The heat source (gas flame or electric elements) is located above the metal, heating it from the top down through radiation.

These are designed for large-scale, continuous melting. They act as a central reservoir of molten metal that can feed multiple casting stations, making them a cornerstone of high-volume foundries.

Understanding the Trade-offs: Gas vs. Electric

The choice of heating method is one of the most significant decisions, carrying direct implications for cost, control, and quality.

Gas-Fired Furnaces

Gas-fired systems are often favored for their lower initial capital cost and their ability to heat metal very quickly.

However, they can offer less precise temperature control, and the byproducts of combustion can sometimes introduce impurities into the melt. This can lead to slightly higher rates of metal loss (dross).

Electric Resistance Furnaces

Electric furnaces provide exceptionally precise temperature control and a much cleaner melting environment, as there is no combustion.

This results in higher metal quality, lower melt loss, and better overall energy efficiency. The primary trade-off is typically a higher initial purchase and installation cost compared to a gas-fired equivalent.

Making the Right Choice for Your Goal

Selecting a furnace is not about finding the "best" one, but the one that is best suited for your specific operational needs.

- If your primary focus is flexibility and frequent alloy changes: A gas-fired or electric resistance crucible furnace is the most practical and common choice.

- If your primary focus is high-volume, continuous production: A large central reverberatory furnace paired with smaller holding furnaces at each casting station is the standard industrial model.

- If your primary focus is achieving the highest metal quality and efficiency: A specialized electric resistance furnace, such as a wet bath reverberatory model, is the superior option.

Ultimately, selecting the right furnace is about aligning the technology's strengths with your specific production goals and quality requirements.

Summary Table:

| Furnace Type | Best For | Heating Method | Key Advantage |

|---|---|---|---|

| Crucible Furnace | Job shops, small batches, alloy changes | Gas or Electric | Flexibility, easy cleaning |

| Reverberatory Furnace | High-volume production, continuous melting | Gas or Electric | Large-scale melting capacity |

| Electric Resistance | High metal quality, efficiency, low melt loss | Electric | Precise temperature control |

| Gas-Fired | Fast melting, lower initial cost | Gas | Rapid heat-up, cost-effective |

Ready to Optimize Your Metal Casting Process?

Choosing the right furnace is critical to your operation's efficiency, cost, and final product quality. At KINTEK, we specialize in providing high-performance lab and industrial equipment tailored to your specific metal casting needs.

We help you:

- Increase efficiency with precise temperature control and reduced melt loss.

- Scale production with furnaces designed for high-volume or flexible batch operations.

- Achieve superior metal quality using clean, reliable electric heating technology.

Whether you're a job shop requiring flexibility or a large foundry focused on continuous production, KINTEK has the equipment and expertise to support your goals.

Contact us today to discuss your requirements and let our experts guide you to the ideal furnace solution for your success.

Get in touch with our team now →

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

People Also Ask

- What is the basic construction and temperature control mechanism of a laboratory tube furnace? Master Precision Heating for Your Lab

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation