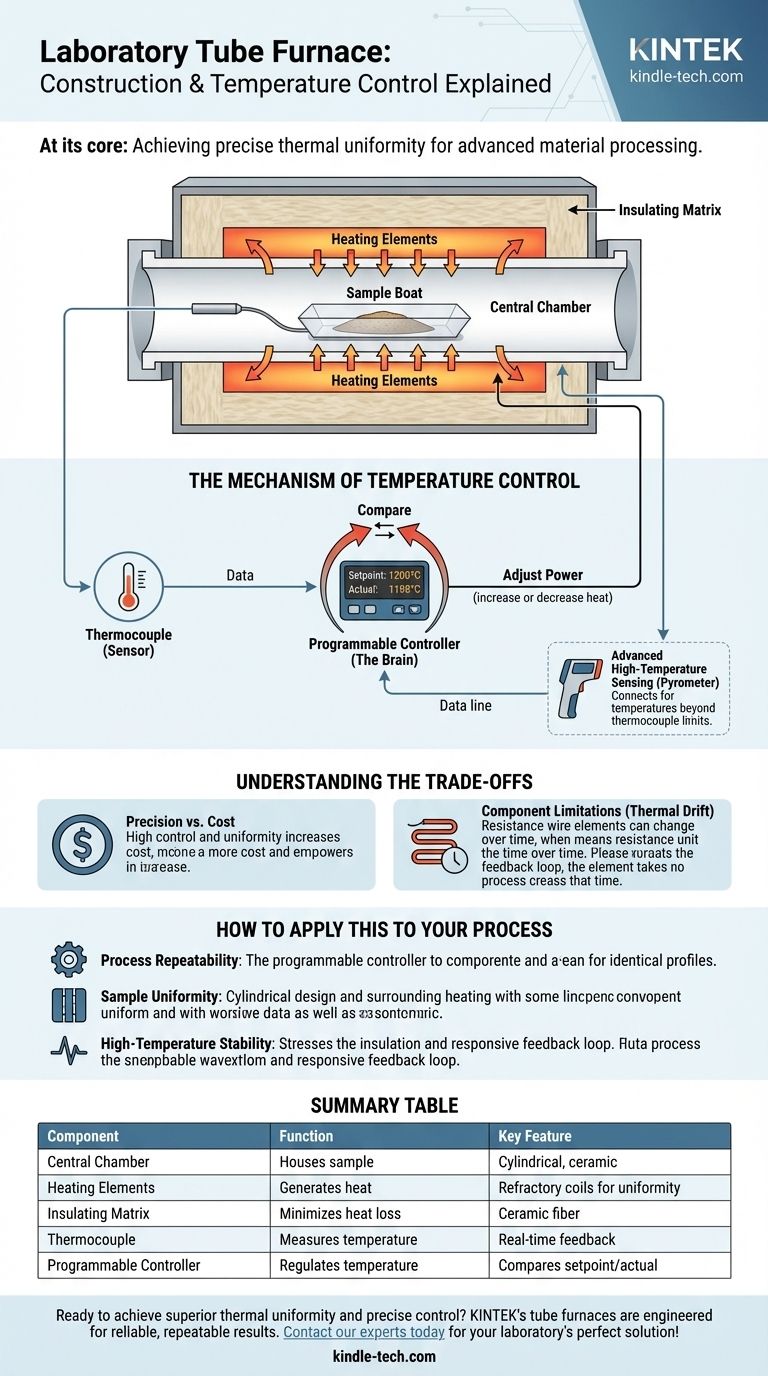

At its core, a laboratory tube furnace is a high-temperature heating device built around a central cylindrical chamber. This chamber is enclosed by heating elements embedded in a thermal insulation matrix, and its temperature is precisely managed by a feedback loop controlled by a thermocouple.

The design of a tube furnace is entirely focused on a single objective: creating a highly uniform and precisely controlled temperature zone within a cylindrical space for advanced material processing and analysis.

The Core Components of Construction

A tube furnace's effectiveness stems from the synergistic function of three primary components. Each part is engineered to contribute to thermal stability and uniformity.

The Central Chamber

The heart of the furnace is its cylindrical cavity or tube. This chamber is where the sample is placed for processing. It is typically surrounded by a circular wall made from high-temperature ceramics.

The Heating Elements

To generate heat, refractory heating coils or bands are embedded within this ceramic material. Their placement completely surrounds the central chamber, ensuring that heat is applied evenly from all directions. This design is critical for achieving high thermal uniformity.

The Insulating Matrix

The entire heating assembly is encased in a thermally insulating material, such as ceramic fiber. This insulation serves a crucial purpose: it minimizes heat loss to the surrounding environment, which helps maintain a stable internal temperature and improves energy efficiency.

The Mechanism of Temperature Control

Achieving and maintaining a precise temperature is not a passive process. It relies on a sophisticated, active feedback system.

The Thermocouple: The Primary Sensor

A thermocouple is a sensor that measures the temperature inside the chamber. It constantly relays this information back to the central control unit. This real-time data is the foundation of the entire control system.

The Programmable Controller: The Brain

The programmable temperature controller acts as the furnace's brain. It compares the actual temperature measured by the thermocouple to the desired temperature (the "setpoint") programmed by the user.

If the temperature is too low, the controller sends more power to the heating elements. If it's too high, it reduces the power. This continuous cycle of measuring and adjusting allows for incredibly precise temperature regulation, including programmed rates of temperature rise and fall.

Advanced High-Temperature Sensing

For extremely high temperatures that could damage a standard thermocouple, some advanced systems incorporate a pyrometer. The controller can be programmed to switch from using the thermocouple to the pyrometer at a specific temperature, protecting the sensor from overheating while maintaining control.

Understanding the Trade-offs

While highly effective, the design of a tube furnace presents specific trade-offs that are important to understand.

Precision vs. Cost

The sophisticated control systems and specialized construction required for high thermal uniformity make tube furnaces generally more expensive than simpler designs like muffle furnaces. You are paying for a higher degree of control.

Component Limitations

The heating elements themselves, often made of resistance wire, can experience thermal drift over time. This is a slow change in their electrical resistance at a given temperature, which can affect heating accuracy. The feedback loop from the thermocouple is essential to continuously correct for this and other potential instabilities.

How to Apply This to Your Process

Choosing and using a tube furnace effectively means aligning its capabilities with your specific scientific or industrial goal.

- If your primary focus is process repeatability: The programmable controller is your most critical tool, allowing you to execute identical, complex temperature profiles every time.

- If your primary focus is sample uniformity: The cylindrical design with surrounding heating elements is the key feature ensuring your entire sample experiences the same thermal conditions.

- If your primary focus is high-temperature stability: The combination of robust insulation and a responsive thermocouple feedback loop is what guarantees a stable and predictable heating environment.

Ultimately, a tube furnace is an instrument of precision, designed from the ground up to provide a controlled and uniform thermal environment.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Central Chamber | Houses the sample | Cylindrical, high-temperature ceramic |

| Heating Elements | Generates heat | Refractory coils for uniform heating |

| Insulating Matrix | Minimizes heat loss | Ceramic fiber for efficiency |

| Thermocouple | Measures temperature | Provides real-time feedback |

| Programmable Controller | Regulates temperature | Compares setpoint to actual temperature |

Ready to achieve superior thermal uniformity and precise temperature control in your lab processes? KINTEK's tube furnaces are engineered for advanced material processing and analysis, providing the reliable, repeatable results your research demands. Contact our experts today to find the perfect solution for your laboratory's specific heating needs!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What role does a low-temperature annealing furnace play in Na2S-NPS-C production? Enhance Stability & Performance

- What is the function of a high-vacuum tube furnace in graphene CVD? Optimize Synthesis for High-Quality Nanomaterials

- What are the primary functions of a high-temperature tube furnace for iridium-based inverse opals? Expert Annealing Guide

- What role does a high-temperature tube furnace play in the synthesis of micro-mesoporous graphene? Precision Engineering

- What role does a high-temperature tube furnace or muffle furnace play in the production of LiNbO3? Enhance Coatings.

- What is pyrolysis in biogas? A High-Temperature Process for Syngas, Bio-Oil, and Bio-Char

- Why is a multi-channel flow-controlled gas tube furnace necessary for g-CNTs? Master Graphene-Nanotube Synthesis

- What is the purpose of using vacuum-sealed glass tubes for Thio-LISICON sintering? Optimize Solid Electrolyte Purity