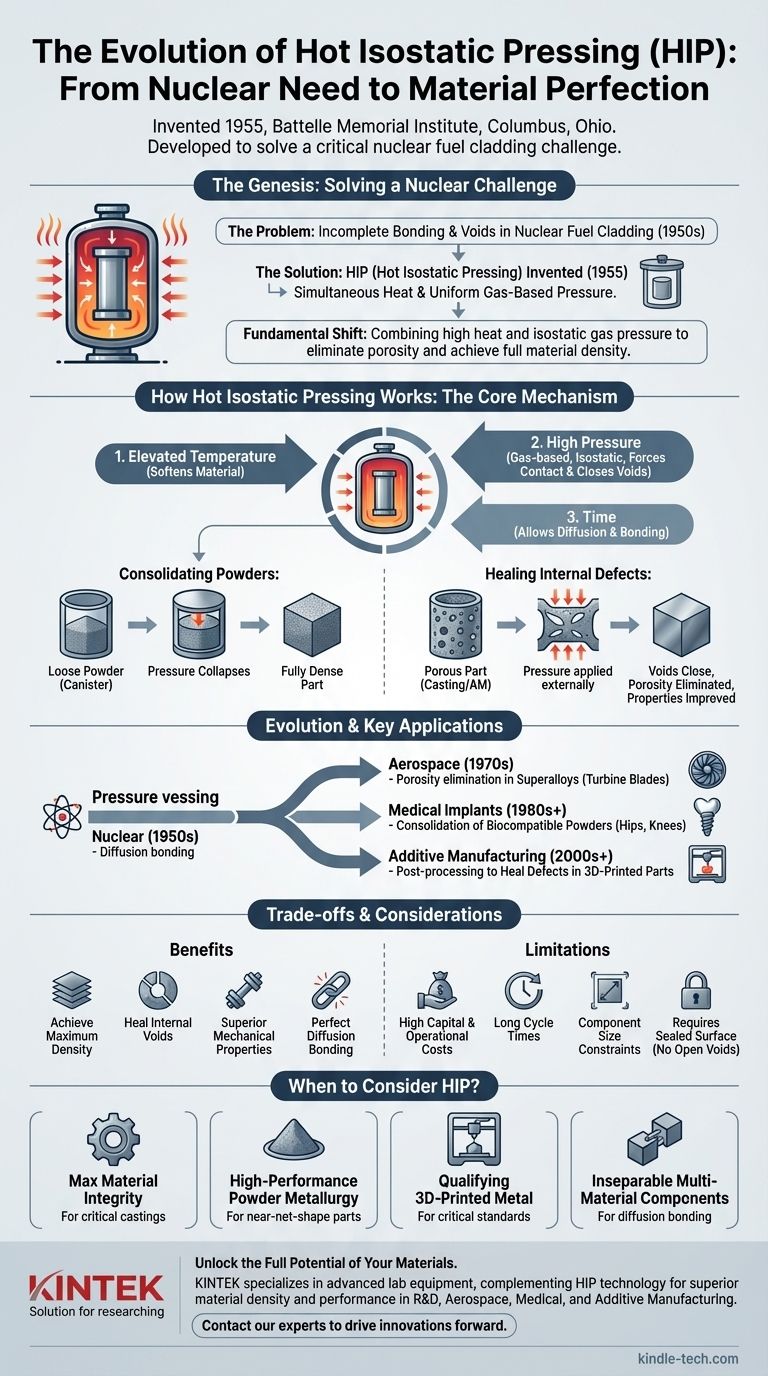

Invented in the mid-1950s, Hot Isostatic Pressing (HIP) was formally developed in 1955 by researchers at the Battelle Memorial Institute in Columbus, Ohio. The technology was not created for general-purpose manufacturing but to solve a highly specific and critical challenge in the nuclear industry: diffusion bonding a protective cladding onto nuclear fuel elements.

The invention of Hot Isostatic Pressing was a fundamental shift in materials processing. By combining high heat with uniform, gas-based pressure, it unlocked the ability to eliminate internal porosity and achieve full material density, creating parts with superior mechanical properties that were previously unattainable.

The Genesis of HIP: Solving a Nuclear Challenge

The original problem that HIP was designed to solve was one of extreme consequence. In a nuclear reactor, perfect contact between the uranium fuel and its protective cladding is essential for efficient heat transfer and safety.

The Problem of Incomplete Bonding

Traditional methods of bonding or cladding materials often left microscopic voids or areas of incomplete contact. In a nuclear environment, these tiny gaps would inhibit heat transfer, leading to dangerous hot spots and potential fuel failure.

The Battelle Innovation

The team at Battelle conceived of a new approach. They proposed placing the components inside a sealed vessel, heating them to a high temperature below their melting point, and simultaneously pressurizing the vessel with a high-pressure inert gas.

The "Isostatic" Breakthrough

The key was using a gas (typically Argon) as the pressure-transmitting medium. Unlike a mechanical press, which applies force in one direction, the gas exerted uniform, or "isostatic," pressure on the component from every direction. This forced the two materials into intimate, atom-to-atom contact, creating a perfect metallurgical bond free of any voids.

How Hot Isostatic Pressing Fundamentally Works

The process is a precise interplay of three critical parameters, each controlled within a specialized pressure vessel. This combination is what allows HIP to fundamentally alter a material's internal structure.

The Three Key Parameters

The core of the HIP process is the simultaneous application of elevated temperature, high pressure, and time. The temperature softens the material, allowing it to become plastic, while the pressure provides the driving force to close internal voids.

Consolidating Powders

One of the most common uses of HIP is in powder metallurgy. A metal powder is sealed in a canister shaped like the final part. During the HIP cycle, the pressure collapses the canister and consolidates the powder into a fully dense, solid part with properties often matching or exceeding those of forged materials.

Healing Internal Defects

HIP is also widely used as a "healing" process for parts made by other methods, such as casting or additive manufacturing (3D printing). The external pressure closes internal gas porosity, micro-shrinkage, and voids, dramatically improving fatigue life and ductility.

Understanding the Trade-offs and Limitations

While powerful, HIP is not a universal solution. Its application involves significant cost and process considerations that must be weighed against its benefits.

High Capital and Operational Costs

HIP systems are expensive, specialized pressure vessels that require significant infrastructure for gas handling and safety. This high capital cost makes the process more expensive than conventional heat treatments.

Long Cycle Times

A typical HIP cycle, including heating, holding at temperature and pressure, and cooling, can take many hours. This batch-processing nature can be a bottleneck in high-volume production environments.

Component Size Constraints

The size of the part that can be treated is limited by the internal dimensions of the HIP vessel's "hot zone." While very large HIP units exist, they are rare and extremely costly to operate.

Requires a Sealed Surface

For healing defects in an existing part, the internal porosity must not be connected to the surface. If a void is open to the outside, the pressure inside and outside the void will equalize, and it will not collapse.

The Evolution Beyond Its Original Purpose

From its niche nuclear application, HIP has become an indispensable process for manufacturing the most demanding components across numerous high-tech industries.

Aerospace Superalloys

HIP became essential for the aerospace industry in the 1970s. It is used to eliminate porosity in cast nickel-based superalloy components, such as jet engine turbine blades, ensuring they can withstand extreme temperatures and stresses.

Medical Implants

The process is critical for producing high-strength, fatigue-resistant medical implants like artificial hips and knees. It consolidates titanium or cobalt-chrome powders into durable, biocompatible final parts.

Additive Manufacturing (3D Printing)

More recently, HIP has become a vital post-processing step for metal 3D printing. It removes the inherent porosity often found in printed parts, transforming them into fully dense components suitable for critical, load-bearing applications.

When to Consider Hot Isostatic Pressing

The decision to use HIP should be driven by a clear performance requirement that other processes cannot meet.

- If your primary focus is achieving maximum material integrity: Use HIP to heal internal voids in critical castings, dramatically improving fatigue life and mechanical reliability.

- If your primary focus is producing high-performance powder metallurgy parts: Use HIP to consolidate metal powders into a fully dense, near-net-shape component with properties equivalent to wrought materials.

- If your primary focus is qualifying 3D-printed metal for critical use: Apply HIP as a crucial post-processing step to remove internal defects and ensure the part meets stringent aerospace or medical standards.

- If your primary focus is creating inseparable multi-material components: Leverage HIP's original strength in diffusion bonding to create a perfect metallurgical bond between dissimilar materials.

Ultimately, Hot Isostatic Pressing is the definitive tool for achieving the theoretical maximum density and performance locked within your advanced materials.

Summary Table:

| Key Milestone | Year | Primary Application |

|---|---|---|

| Formal Invention at Battelle Memorial Institute | 1955 | Diffusion bonding for nuclear fuel elements |

| Adoption by Aerospace Industry | 1970s | Porosity elimination in superalloy castings (e.g., turbine blades) |

| Critical for Medical Implants | 1980s+ | Consolidation of titanium/cobalt-chrome powders |

| Vital for Additive Manufacturing | 2000s+ | Post-processing to heal defects in 3D-printed metal parts |

Ready to unlock the full potential of your materials with Hot Isostatic Pressing?

KINTEK specializes in providing advanced lab equipment and consumables, including solutions for materials testing and processing that complement HIP technology. Whether you are in R&D, aerospace, medical device manufacturing, or additive manufacturing, our expertise can help you achieve superior material density and performance.

Contact our experts today via our Contact Form to discuss how KINTEK can support your laboratory's specific needs and drive your innovations forward.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Is hot isostatic pressing a heat treatment? A Guide to Its Unique Thermomechanical Process

- What is HIP treatment for metal? Eliminate Internal Defects for Superior Part Performance

- What are some of the attractive properties of hot isostatic pressed products? Achieve Perfect Density and Superior Performance

- What is the principle of hot isostatic pressing? Achieve 100% Density and Superior Performance

- What pressure is hot isostatic press? Achieve Full Density & Superior Material Performance