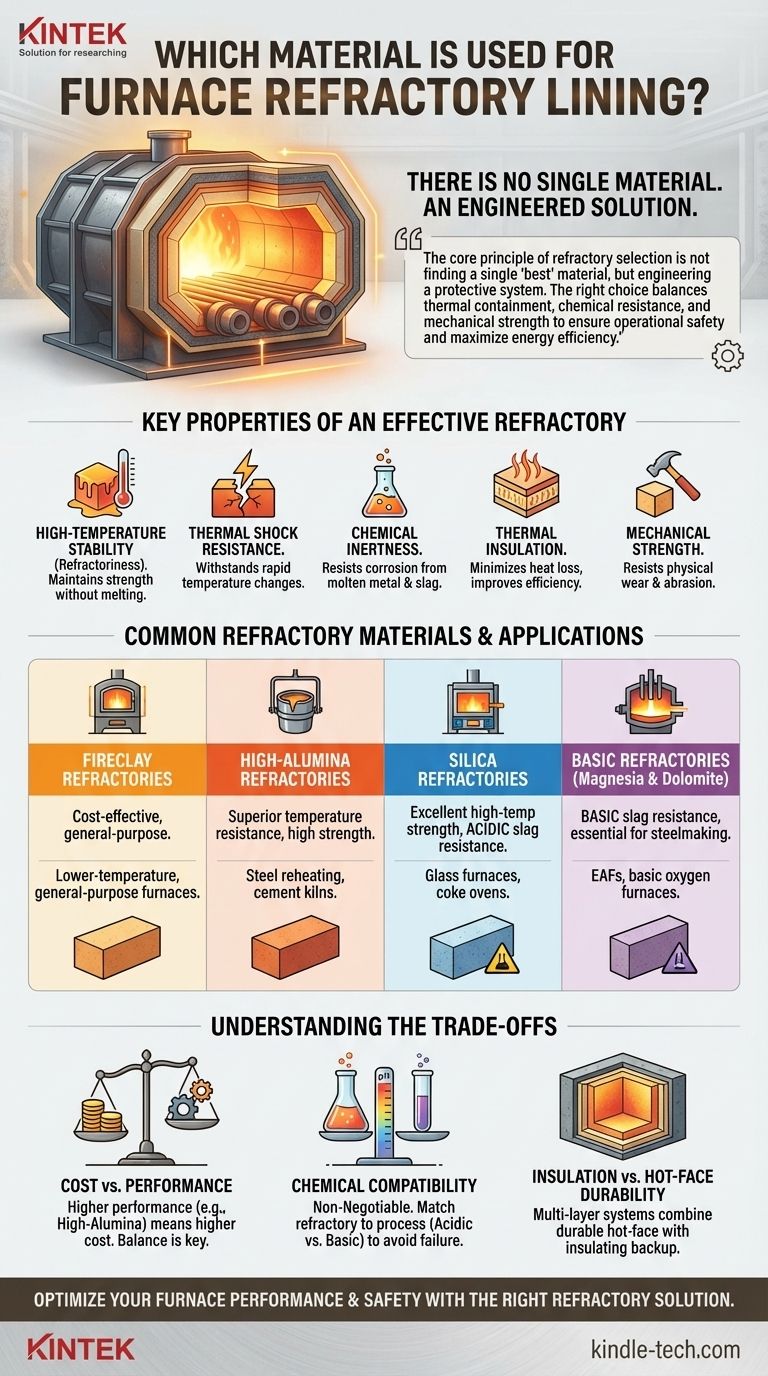

There is no single material for furnace refractory lining; instead, a range of specialized ceramic materials is chosen based on the furnace's operating temperature, the chemical nature of the materials being melted, and cost considerations. The most common families of materials include fireclays for general use, and high-alumina, silica, or magnesia-based refractories for more demanding, specific applications.

The core principle of refractory selection is not finding a single "best" material, but engineering a protective system. The right choice balances thermal containment, chemical resistance, and mechanical strength to ensure operational safety and maximize energy efficiency.

The Fundamental Role of a Refractory Lining

A furnace's refractory lining is the critical barrier that makes high-temperature industrial processes possible. Its primary job is to contain extreme heat and protect the furnace's structural components from thermal, chemical, and physical damage.

The Protective Barrier

Refractory materials stand between the intense heat and molten contents of the furnace and its outer shell or induction system. They prevent the structural steel from weakening or melting and protect sensitive components, like induction coils, from catastrophic failure.

A High-Stakes Environment

This lining must endure a combination of severe stresses simultaneously. It faces direct contact with molten metals, corrosive byproducts called slag, and extreme physical abrasion from charging materials, all while operating at temperatures that would destroy most other materials.

Key Properties of an Effective Refractory

The suitability of a material is defined by a specific set of properties. Understanding these characteristics is key to understanding why certain materials are chosen over others.

High-Temperature Stability (Refractoriness)

This is the most fundamental property. A refractory must maintain its strength and chemical structure at the furnace's maximum operating temperature without melting or softening.

Thermal Shock Resistance

Furnaces undergo rapid temperature changes during startup, shutdown, and charging. The lining must be able to withstand these thermal cycles without cracking, a failure known as thermal shock.

Chemical Inertness

Molten metals and slag can be highly corrosive. The refractory lining must be chemically compatible with the materials it contains to avoid being rapidly eaten away. This is why slag chemistry (acidic vs. basic) is a critical factor in material selection.

Thermal Insulation

An effective lining minimizes heat loss through the furnace walls. Modern systems often use a multi-layer design, featuring lightweight ceramic fibers or insulation boards that reduce energy consumption and improve overall efficiency.

Mechanical Strength

The material must be strong enough to resist the physical wear and tear (abrasion) from solid materials being loaded into the furnace and the erosive force of moving molten metal.

Common Refractory Materials and Their Applications

Different refractories are engineered to excel in different conditions. The main categories are based on their chemical composition.

Fireclay Refractories

Composed primarily of hydrated aluminum silicates, fireclays are the workhorses of the refractory world. They are a cost-effective choice for lower-temperature, general-purpose furnaces where the chemical environment is not overly aggressive.

High-Alumina Refractories

Containing a higher percentage of alumina (aluminum oxide), these materials offer superior temperature resistance and strength compared to fireclays. They are used in steel reheating furnaces, cement kilns, and as part of modern composite lining systems.

Silica Refractories

These materials are over 90% silicon dioxide and exhibit excellent strength at high temperatures. Their key characteristic is resistance to acidic slag, making them the standard choice for glass furnaces and coke ovens.

Basic Refractories (Magnesia & Dolomite)

Composed of magnesium oxide (magnesia) or a combination of magnesia and calcium oxide (dolomite), these are used in environments with basic slag. They are essential in modern steelmaking processes, such as in basic oxygen furnaces and electric arc furnaces.

Understanding the Trade-offs

Selecting a refractory material is always an exercise in balancing competing factors. There is no universally perfect solution.

Cost vs. Performance

Higher-performance materials, such as high-purity magnesia or high-alumina products, carry a significantly higher cost than standard fireclay bricks. The choice often comes down to the lowest acceptable cost for a material that can safely do the job.

Chemical Compatibility is Non-Negotiable

This is the most critical trade-off. Using an acidic refractory (like silica) to contain a basic slag will result in rapid chemical degradation and lining failure. The reverse is also true. The chemical nature of the refractory must match the chemical nature of the process.

Insulation vs. Hot-Face Durability

Materials that are excellent thermal insulators (like ceramic fiber blankets) often lack the density and strength to resist direct contact with molten metal. This is why multi-layer systems are common, combining a durable hot-face brick with a highly insulating backup layer to achieve both goals.

Making the Right Choice for Your Application

Your selection must be guided by the specific demands of your process.

- If your primary focus is general-purpose, lower-temperature applications: Fireclay refractories offer the most cost-effective and reliable solution.

- If you are melting steel or dealing with basic slag: You must use a basic refractory like magnesia or dolomite to prevent rapid chemical failure.

- If your process involves acidic slag (e.g., glassmaking): Silica-based refractories are specifically designed for this chemical environment.

- If your primary goal is maximum energy efficiency and high-temperature performance: A multi-layer system using high-alumina hot-face materials backed by ceramic fiber insulation is the modern standard.

Ultimately, the right refractory lining is an engineered solution that balances thermal performance, chemical compatibility, and cost to ensure safe and efficient furnace operation.

Summary Table:

| Refractory Type | Key Characteristics | Common Applications |

|---|---|---|

| Fireclay | Cost-effective, general-purpose | Lower-temperature, general-purpose furnaces |

| High-Alumina | Superior temperature resistance, high strength | Steel reheating furnaces, cement kilns |

| Silica | Excellent high-temperature strength, acidic slag resistance | Glass furnaces, coke ovens |

| Basic (Magnesia/Dolomite) | Basic slag resistance, essential for steelmaking | Electric arc furnaces, basic oxygen furnaces |

Optimize your furnace performance and safety with the right refractory solution. The correct lining is critical for energy efficiency, process integrity, and equipment longevity. KINTEK specializes in providing high-performance lab equipment and consumables, including expert guidance on furnace systems and their components. Let our specialists help you select the ideal refractory material for your specific application and thermal processing needs. Contact our experts today to discuss your requirements and enhance your laboratory's capabilities.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Graphite Vacuum Continuous Graphitization Furnace

- High Temperature Wear-Resistant Alumina Al2O3 Plate for Engineering Advanced Fine Ceramics

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing

- What is the drying zone in a rotary kiln? Boost Efficiency with Modern Drying Solutions

- How is the operational mode of bed motion selected for a rotary kiln? Optimize Heat Transfer and Material Homogeneity

- How does a rotary extractor work? Master Continuous High-Volume Solid Processing

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker