At their core, ceramics are used for furnace linings because of their exceptional ability to resist extreme heat and prevent its escape. Their unique molecular structure allows them to remain stable at temperatures that would melt metals, while their low thermal conductivity acts as a powerful insulator, ensuring the furnace operates efficiently and safely.

The decision to use ceramic linings is driven by three primary goals: protecting the furnace structure from thermal damage, minimizing energy loss to the environment, and resisting chemical attack from the process itself. This combination directly leads to higher efficiency, better process control, and a longer operational lifespan.

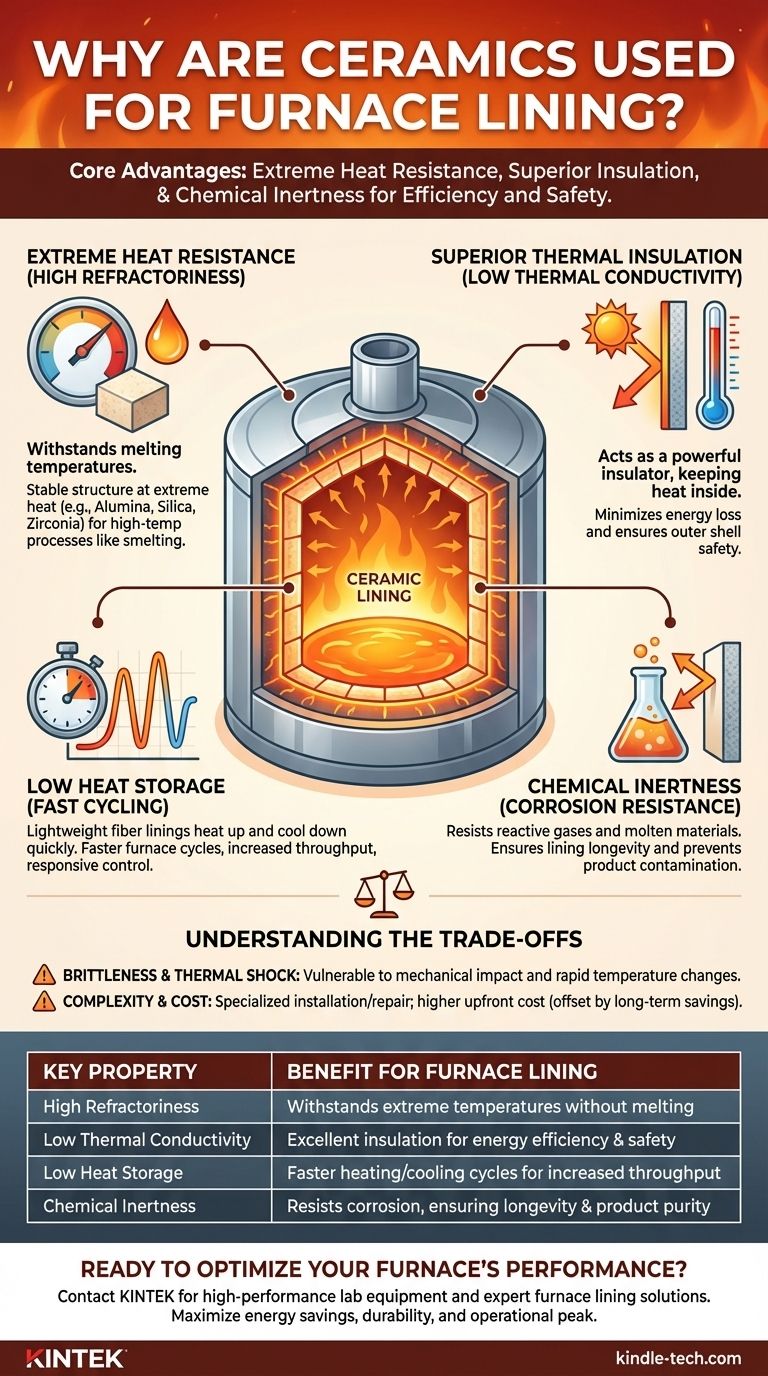

The Critical Properties of Ceramic Linings

To understand why ceramics are the material of choice, we must examine the specific properties that make them uniquely suited for high-temperature environments. These characteristics work in concert to create a stable and efficient thermal barrier.

Extreme Heat Resistance (High Refractoriness)

The most fundamental property is refractoriness—the ability of a material to withstand high temperatures without deforming or melting.

Ceramics, especially materials like alumina, silica, and zirconia, have exceptionally high melting points. This allows furnaces to operate at the extreme temperatures required for processes like metal smelting, glass manufacturing, and chemical synthesis.

Superior Thermal Insulation (Low Thermal Conductivity)

A material's thermal conductivity measures how easily heat passes through it. Ceramics are excellent insulators because they have very low thermal conductivity.

This means that instead of conducting heat to the furnace's outer steel shell, the ceramic lining keeps the thermal energy contained within the hot zone. This is the primary mechanism for achieving energy efficiency and ensuring worker safety.

Low Heat Storage

Modern ceramic linings, particularly those made of ceramic fiber, have the added benefit of low heat storage.

Unlike dense refractory bricks that absorb and hold vast amounts of heat, lightweight ceramic fibers heat up and cool down quickly. This allows for faster furnace cycles, increasing throughput and providing more responsive temperature control.

Chemical Inertness

Furnace atmospheres can be incredibly corrosive, containing reactive gases or molten materials that can degrade the lining.

Most ceramics are chemically inert, meaning they do not easily react with other substances. This resistance to chemical corrosion is critical for ensuring the lining's longevity and preventing contamination of the product being processed.

Understanding the Trade-offs

While ceramics offer unparalleled thermal performance, it is important to acknowledge their limitations. No material is perfect, and selecting a lining involves balancing competing priorities.

Brittleness and Thermal Shock

The primary trade-off for ceramics is their inherent brittleness. Unlike metals, they can crack under direct mechanical impact or from the stress of rapid temperature changes, a phenomenon known as thermal shock.

Careful design and the selection of appropriate ceramic grades (e.g., fiber vs. dense brick) are necessary to mitigate this risk based on the specific furnace operation.

Installation and Repair Complexity

Installing and repairing ceramic linings is a specialized skill. Whether laying bricks or anchoring fiber modules, the process requires precision to ensure a complete thermal seal with no hot spots.

Repairs can sometimes be more complex and time-consuming compared to linings made from monolithic castables, potentially leading to longer downtime.

Upfront Material Cost

High-performance ceramics can have a higher initial material cost compared to lower-grade refractories or traditional insulation.

However, this cost is frequently justified over the furnace's lifetime through significant energy savings, reduced maintenance cycles, and improved product quality, resulting in a lower total cost of ownership.

Selecting the Right Ceramic for Your Application

The term "ceramic" covers a wide range of materials, from dense bricks to lightweight fibers. The optimal choice depends entirely on your primary operational goal.

- If your primary focus is maximum energy efficiency: Choose a lining with the lowest possible thermal conductivity, such as a multi-layered system with ceramic fiber blankets.

- If your primary focus is durability against abrasion: Opt for dense, hard-wearing materials like high-alumina refractory bricks or castables in impact-prone areas.

- If your primary focus is rapid process cycling: Prioritize low-density materials with low heat storage, like ceramic fiber modules, to minimize heat-up and cool-down times.

Ultimately, choosing the correct ceramic lining is a strategic decision that directly governs your furnace's efficiency, reliability, and operational cost.

Summary Table:

| Key Property | Benefit for Furnace Lining |

|---|---|

| High Refractoriness | Withstands extreme temperatures without melting |

| Low Thermal Conductivity | Excellent insulation for energy efficiency & safety |

| Low Heat Storage | Faster heating/cooling cycles for increased throughput |

| Chemical Inertness | Resists corrosion, ensuring longevity & product purity |

Ready to optimize your furnace's performance and efficiency? The right ceramic lining is a strategic investment that directly impacts your operational costs, product quality, and equipment lifespan. At KINTEK, we specialize in providing high-performance lab equipment and consumables, including expert solutions for your furnace lining needs. Our team can help you select the ideal ceramic material—whether for maximum energy savings, rapid cycling, or superior durability—to ensure your laboratory operates at its peak.

Contact our experts today for a personalized consultation and discover the KINTEK difference in reliability and performance.

Visual Guide

Related Products

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- High Quality Alumina Ceramic Screw for Engineering Advanced Fine Ceramics with High Temperature Resistance and Insulation

- Custom Boron Nitride (BN) Ceramic Parts

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the application of SiC for energy? Revolutionizing Power Electronics for Maximum Efficiency

- What is zirconia in biomedical applications? A High-Strength, Biocompatible Ceramic for Implants

- What are the classification of ceramic powder? A Guide to Selecting the Right Material for Your Application

- Where are ceramics used in the body? Key Applications in Orthopedics, Dentistry & Bone Repair

- What are the drawbacks of tungsten carbide? Understanding the Brittleness vs. Hardness Trade-off

- What are the synthesis methods of SiC? From Industrial Abrasives to High-Performance Electronics

- Why does sintering increase density? Unlock the Secrets to Superior Material Performance

- Why is ceramic sintering used? To transform fragile powder into a strong, dense solid.